Your TPU parts pop out of the mold, looking pretty good. But are they truly finished? Sometimes, hidden issues or the need for a better look means more work.

Post-processing TPU injection molded parts often involves annealing for improved dimensional stability, surface treatments like painting or printing for aesthetics and durability, and assembly techniques such as welding or adhesive bonding to create the final functional product.

So, the injection molding machine has done its job, and you’ve got a batch of freshly minted TPU components. You might think, "Great, job done!" And sometimes, it is. But often, to get that part from just "molded" to "market-ready," there are a few more crucial steps. I’ve learned over the years that these finishing touches can make all the difference in performance, appearance, and overall quality. It’s these extra steps, the post-processing, that can truly elevate your TPU parts. Let’s explore what these techniques are and why they matter.

Does Injection Molding Always Require Post-Processing, You Wonder?

It’s a fair question. You’ve invested in a good mold, dialed in your machine. Do you really need to do more? Well, it’s not always a straight yes or no.

Not every injection molded TPU part requires post-processing. The necessity depends heavily on the specific application, the complexity of the part, cosmetic requirements, and whether it needs to be assembled with other components.

I’ve seen plenty of TPU parts, like simple industrial washers or bumpers, go straight from the mold to the assembly line, and they work perfectly fine. But then there are other cases—think of a consumer electronic housing made of TPU or a medical device component—where post-processing is absolutely non-negotiable. It really boils down to the end-use and the standards you need to meet.

So, what makes us decide? Here are a few things I always consider:

- Dimensional Stability & Tolerances: TPU, like any plastic, shrinks as it cools. If your part needs to hold super tight dimensions, or if it’s a bit stressed from the molding process, a step like annealing might be crucial.

- Appearance: Is it a customer-facing part? Then color consistency, gloss level, and freedom from blemishes are paramount. This is where surface treatments shine.

- Functionality: Does the part need to be bonded to something else? Does it need specific markings? Will it be subjected to harsh environments? These functional needs often dictate post-processing.

-

Molding Imperfections: Even with the best process, tiny bits of flash (excess material at parting lines) or gate vestiges (where the plastic entered the mold) might need to be trimmed.

Here’s a quick way I think about it for clients like Michael, who’s making components for consumer electronics where both function and aesthetics are key:Scenario Post-Processing Likely Needed? My Usual Rationale Simple, internal TPU grommet Rarely Basic function, usually hidden, loose tolerance okay. High-precision TPU seal for a device Often (Annealing, deflashing) Needs exact dimensions, clean edges for sealing. Consumer-facing TPU phone case Almost Always (Surface work) Aesthetics (color, feel), branding (printing), durability. TPU part needing strong bond to metal Yes (Surface preparation) Adhesion is tricky with TPU; prep is key. Complex TPU overmolded handle grip Often (Deflashing, texturing) Clean finish, good grip feel. So, while not always required, post-processing is a powerful set of tools in our arsenal to ensure TPU parts perform and look their best. Sometimes, skipping it is a false economy. I remember one project where a client initially skipped annealing on some critical TPU seals to save a few cents per part. They ended up with field failures due to dimensional changes over time, costing them way more in the long run. A simple post-molding annealing step fixed it right up!

So, How is TPU Processed Before We Even Think About Post-Processing?

Before we get too deep into fixing and finishing, it helps to quickly understand how these TPU parts are made in the first place. Knowing the main manufacturing route gives context to why some post-processing steps are needed.

TPU is predominantly processed using injection molding. This involves melting the TPU pellets and injecting the molten material under high pressure into a precisely machined mold cavity where it cools and solidifies into the desired shape.

Now, when I say "processed," for TPU parts, nine times out of ten, we’re talking about injection molding. Sure, TPU can be extruded into films or tubes, or even sometimes blow-molded, but for discrete parts, especially complex ones, injection molding is king. It’s efficient for high volumes and can produce really intricate geometries.

One thing I can’t stress enough when processing TPU—and this happens before it even sees the inside of the molding machine—is drying. TPU is hygroscopic, meaning it loves to suck moisture out of the air like a sponge. If you try to mold wet TPU, you’re asking for trouble: splay marks, brittleness, bubbles, you name it. I’ve seen perfectly good molds produce garbage parts simply because the material wasn’t dried properly. So, proper drying in a desiccant dryer, usually for a few hours at a specific temperature (check the supplier’s datasheet!), is step zero.

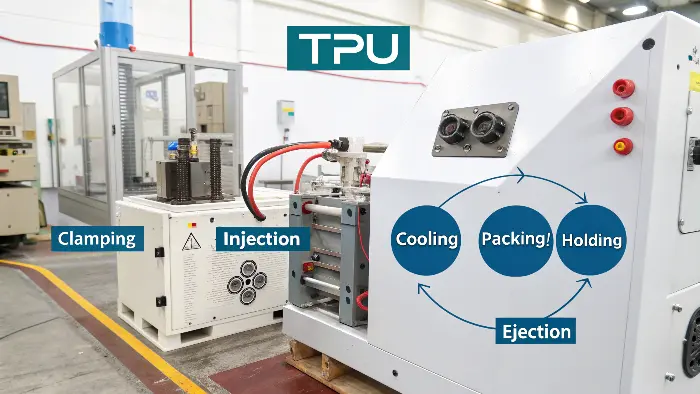

Once it’s dry, the basic flow of injection molding TPU looks something like this:

- Melting & Plasticizing: The dried TPU pellets are fed into the barrel of the injection molding machine, where a screw melts them and mixes them into a homogenous molten state.

- Injection: The screw then pushes this molten TPU forward at high speed and pressure, injecting it into the closed mold cavity.

- Packing & Holding: After the cavity is mostly full, additional pressure (holding pressure) is applied to pack more material in to compensate for shrinkage as it cools.

- Cooling: The mold is cooled (usually with circulating water), allowing the TPU part to solidify. This is often the longest part of the cycle.

- Ejection: Once solid enough, the mold opens, and the part is ejected.

These steps, if not perfectly controlled, can introduce issues that post-processing aims to correct. For example, stresses can build up during rapid cooling, leading to a need for annealing. Or the gate, where the plastic enters, might leave a mark that needs trimming. Understanding this main process helps us appreciate why we might need those finishing touches. It’s all connected!Could You Outline the 4 Stages of Injection Molding That Might Affect TPU Parts?

You got it. While we just touched on the flow, let’s break down the core injection molding cycle. Knowing these stages helps pinpoint where potential issues that necessitate post-processing for TPU might arise.

The four primary stages of the injection molding cycle are clamping, injection, cooling (which includes packing/holding), and ejection. Each stage has specific parameters critical for TPU that can influence the final part’s quality and need for finishing.

I always tell my team, thinking about these stages isn’t just academic; it’s practical troubleshooting. When a TPU part comes out wrong, we walk back through these stages in our minds.

- Clamping: This is where the two halves of the mold are brought together and held shut with immense force. For TPU, especially softer grades, if your clamp force isn’t high enough to counteract the injection pressure, you can get "flash" – thin films of TPU squeezing out at the parting line. Guess what? That flash needs to be removed, which is a post-processing step (deflashing).

- Injection: Here, the molten TPU is shot into the mold cavity. The speed and pressure are critical. Too fast, and you can degrade the TPU through shear heating, causing burns. Too slow, and it might cool before filling the part, leading to a "short shot." The way TPU flows can also create weld lines or internal stresses. These aren’t always visible immediately but can affect strength or lead to dimensional changes later.

- Cooling (and Packing/Holding): This is usually the longest stage. As the TPU cools and solidifies, it shrinks. The "packing" or "holding" pressure phase pushes a bit more material in to compensate for this. If cooling is uneven, or if the part has thick and thin sections cooling at different rates (very common!), you can get warpage or sink marks. Internal stresses also get locked in here. This is prime territory for why annealing is so often needed for TPU.

-

Ejection: Once the part is cool enough, the mold opens, and ejector pins push the part out. If the TPU is still a bit too soft, or if the ejector pin design isn’t optimal, you can get pin marks, distortion, or even tears. These might need to be trimmed or smoothed.

Let’s put it in a table for clarity:Molding Stage Key Action Potential TPU Issue Leading to Post-Processing Example Post-Processing Fix Clamping Mold halves close & are held under pressure. Insufficient force leads to flash. Manual or automated deflashing. Injection Molten TPU forced into mold cavity. Flow lines, weld lines, shear degradation, stress. Surface treatment, Annealing. Cooling/Packing Part solidifies; shrinkage compensated. Warpage, sink marks, internal stresses. Annealing, Fixturing during cooling. Ejection Mold opens, part removed. Ejector pin marks, distortion, scuffs. Trimming, Surface smoothing, Annealing. You see, each stage has its own gremlins that can pop up, especially with a material like TPU that can be a bit more sensitive than, say, rigid polypropylene. I remember a project with intricate TPU bellows. We struggled with them distorting during ejection. We tweaked the cooling time, the ejection speed, even the ejector pin layout, and eventually added a post-mold cooling fixture to hold their shape. It’s all part of mastering the material!

What Specific Post-Processing Techniques Enhance TPU Parts, Then?

Alright, we know why we might need it and how the molding process influences it. So, what are the actual tools and techniques we use to give those TPU parts the final polish or functionality?

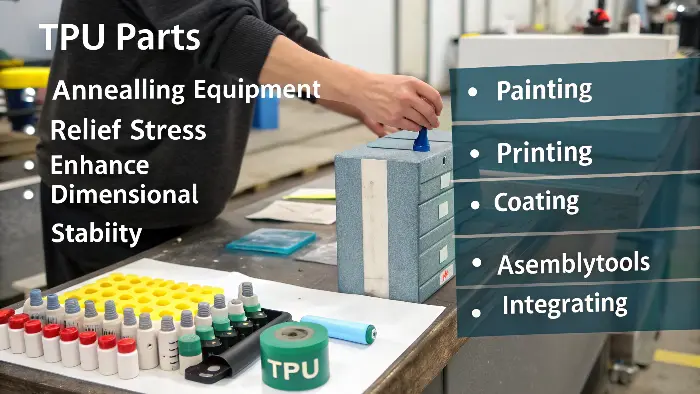

Key post-processing for TPU includes annealing to relieve stress and boost dimensional stability, various surface treatments (like painting, printing, or coating) for aesthetics and protection, and assembly methods if the TPU part is a component in a larger product.

This is where my insights from years of working with TPU really come into play. We’re moving beyond just getting the part out of the mold to actually perfecting it.

Annealing: The Stress Reliever for TPU

Think of annealing as a spa day for your TPU parts. It’s a heat treatment process done after molding. You heat the parts to a temperature below their melting point, hold them there for a specific time, and then cool them slowly and controllably.

- Why do it for TPU? The biggest reason is to relieve molded-in stresses. These stresses are almost inevitable due to the rapid cooling and pressure changes during molding. They can cause parts to warp or change dimensions over time, especially if exposed to temperature fluctuations. Annealing helps achieve better dimensional stability. It can sometimes even improve certain mechanical properties like creep resistance or compression set.

- How it’s done: Typically, TPU parts are placed in an oven. Temperatures might range from 70°C to 110°C (160°F to 230°F), but this is highly dependent on the specific TPU grade. The supplier datasheet is your best friend here! Soak times can vary from a few hours to even 20+ hours for some critical applications. Slow, controlled cooling is also vital.

I often recommend annealing for Michael’s kind of products – consumer electronics – where a TPU button or seal needs to maintain its precise shape and feel for years. It’s a relatively simple step that adds a lot of reliability.Surface Treatments: Making TPU Look, Feel, and Perform Better

TPU often comes out of the mold with a decent surface, but "decent" might not cut it for a high-end product.

- Painting & Coating: This is common for aesthetics (custom colors, gloss/matte finishes) or functional reasons (UV protection, improved chemical resistance, soft-touch feel). TPU can be a bit tricky to paint because it’s flexible and often has low surface energy, meaning paint doesn’t want to stick. So, proper surface preparation (cleaning, sometimes a primer or adhesion promoter like plasma treatment) is essential.

- Printing & Marking: For logos, instructions, or decorative patterns. Pad printing and screen printing can work, but again, adhesion can be a challenge. Laser marking is often an excellent choice for TPU as it can create durable, precise marks without solvents or inks. I’ve used laser marking on TPU watch bands and cables with great success.

- Texturing (Secondary): While much texturing is done in the mold, sometimes a light secondary texturing process like vapor honing or a very gentle abrasive blast can modify the gloss level or improve the tactile feel.

- Surface Energy Modification: For really tough adhesion challenges (paints, inks, or adhesives), treatments like plasma or corona discharge can chemically alter the TPU surface to make it much more receptive. This was a game-changer for one of Michael’s wearable projects where the paint on a TPU strap kept peeling until we introduced plasma treatment.

Assembly: When TPU is Part of a Bigger Picture

Often, a TPU part isn’t a standalone product; it’s a component that needs to be joined to other parts (TPU or different materials).

- Welding: For TPU-to-TPU joints, ultrasonic welding is quite common and effective. It uses high-frequency vibrations to create frictional heat and melt the interface. Heat staking (melting a TPU stud to form a rivet head) and RF (Radio Frequency) welding can also be used for specific TPU types and applications.

- Adhesive Bonding: This is probably the most common way to join TPU to other materials. Success hinges on choosing the right adhesive (cyanoacrylates with a primer, specialized polyurethane adhesives, or some UV-curable adhesives work well) and, critically, surface preparation. Cleaning is a must, and often, a primer or surface treatment like plasma is needed to get a strong, durable bond on low-surface-energy TPU.

- Mechanical Fasteners: Good old screws, rivets, or clips can be used. For screws, you can design self-threading features into harder TPUs, or more commonly, use threaded inserts that are molded-in or heat-staked post-molding. Snap-fit designs are also very popular with TPU due to its flexibility, allowing for easy assembly and disassembly.

Each of these techniques requires its own expertise and equipment, but they open up a world of possibilities for creating complex, functional, and beautiful TPU products.Conclusion

Post-processing isn’t an afterthought; it’s a vital part of producing high-quality TPU injection molded parts. From annealing to surface treatments and assembly, these steps ensure your components meet all functional and aesthetic requirements. Master these, and you’ll master TPU.