Are you puzzled by how countless plastic items are made? It can seem like a hidden, complex world, but understanding it unlocks key manufacturing insights. This article will clearly explain injection mold manufacturing and its essential technology for you.

Injection mold manufacturing is a primary method for mass-producing parts by injecting molten material, typically plastic, into a custom-designed mold cavity. Once the material cools and solidifies, it takes the precise shape of the mold. This technique is exceptionally efficient for creating high volumes of identical items with great accuracy.

Now that we have a basic idea, let’s explore this fascinating technology further. I remember when I first started in a mold factory, the sheer precision of it all amazed me. We’ll break down the details so you can see it too, and understand why it’s so widely used.

What is the technology of injection molding?

Ever wondered what "injection molding technology" truly means? It sounds technical, and not knowing can make you feel out of the loop in manufacturing discussions. Let’s clear up what this essential technology involves, making it easy to understand.

Injection molding technology is a manufacturing method that produces parts by injecting molten material into a mold. The core idea is simple: melt material, force it into a shaped cavity, let it cool, and then remove the finished part. This technology is vital for creating complex and precise components efficiently.

At its heart, injection molding technology uses a mold, which is a hollow block filled with the shape of the part you want to make. Think of it like a very advanced jelly mold. We take a material, usually a type of plastic called a thermoplastic polymer, and heat it until it’s molten. Then, this molten material is forced under high pressure into the mold cavity. I’ve seen so many materials used, from common polypropylene for everyday items to specialized engineering plastics for high-performance applications.

Once inside the mold, the material cools down and hardens, taking on the exact shape of the cavity. This transformation from liquid to solid is crucial. The choice of material is also very important. Different plastics have different properties, like strength, flexibility, or heat resistance. For example, ABS is great for its toughness, while polycarbonate offers high impact resistance.

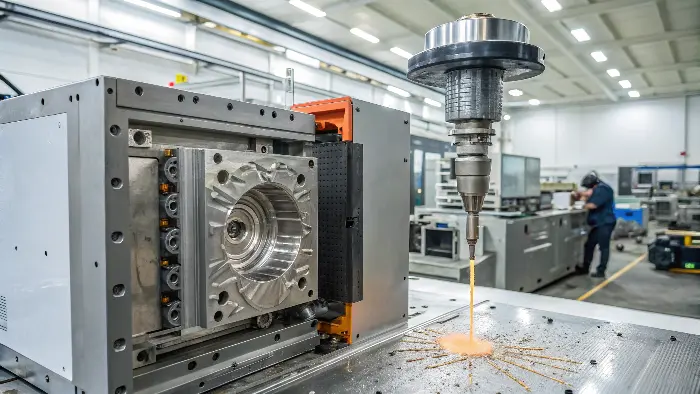

This technology allows for incredible precision and the creation of very complex shapes. Features like screw threads, living hinges, or intricate surface textures can be molded directly into the part. This reduces the need for later assembly or finishing steps, saving time and money. The mold itself has to be made with extreme accuracy, often using CNC machining, to achieve this level of detail.

| Aspect | Description | Example |

|---|---|---|

| Material Input | Typically thermoplastic or thermosetting polymers in pellet form. | Polypropylene (PP), ABS, Nylon (PA) |

| Process | Melting, injecting, packing, cooling, and ejecting. | High-pressure injection into a mold |

| Output | Solidified parts with precise geometry and good surface finish. | Electronic casings, bottle caps, toys |

| Key Advantage | High production rates, complex geometries, excellent repeatability. | Mass production of identical items |

Understanding this technology is the first step to appreciating how so many everyday items are made. It’s a sophisticated blend of material science, mechanical engineering, and process control.

What is the manufacturing process of injection molding?

Knowing what injection molding is is one thing, but how does it actually happen step-by-step? The sequence can seem complicated, making it hard to grasp the whole picture. Let’s walk through the manufacturing process clearly.

The injection molding manufacturing process generally involves four main stages: clamping, injection, cooling, and ejection. First, the two halves of the mold are securely closed. Then, molten material is injected into the mold cavity. Next, the material cools and solidifies. Finally, the mold opens, and the part is ejected.

Let’s break down each stage of the injection molding cycle. It’s a repetitive process, and each step is critical for producing good quality parts.

Stage 1: Clamping

Before any plastic is injected, the two halves of the mold tool must be securely closed. An injection molding machine has a clamping unit, usually hydraulic or electric, that provides the force to hold the mold halves together. This force must be strong enough to counteract the pressure of the molten plastic being injected. If the clamp isn’t strong enough, the mold could push open slightly, causing molten plastic to seep out, creating a defect called "flash." I’ve seen this happen, and it leads to wasted material and extra cleanup work. The required clamping force depends on the projected area of the part and the injection pressure.

Stage 2: Injection

Once the mold is clamped shut, the raw plastic material, usually in the form of small pellets, is fed from a hopper into the injection unit’s barrel. Inside the barrel, a reciprocating screw melts the plastic through heating bands and frictional heat from its rotation. The screw then moves forward like a plunger, forcing the molten plastic under high pressure through a nozzle, then through the mold’s sprue, runners, and gates, and finally into the cavity. The amount of material injected, known as the "shot size," is precisely controlled.

Stage 3: Cooling

After the molten plastic fills the cavity, it begins to cool and solidify, taking the shape of the mold. Cooling time is a significant part of the overall cycle time and can greatly impact production efficiency and part quality. Molds are designed with internal cooling channels through which water or oil circulates to remove heat from the plastic. Proper and uniform cooling is essential to prevent defects like warping or sink marks. I remember optimizing cooling times was always a big focus to improve output.

Stage 4: Ejection

Once the part has cooled sufficiently and is solid, the clamping unit opens the mold. An ejection system, typically consisting of ejector pins or plates, then pushes the solidified part out of the mold cavity. The part may fall onto a conveyor belt, be collected in a bin, or be removed by a robotic arm. The machine is then ready to close the mold and begin the next cycle.

| Stage | Action | Key Consideration |

|---|---|---|

| Clamping | Mold halves are closed and held under high pressure. | Sufficient and consistent clamping force |

| Injection | Molten plastic is forced into the mold cavity at high pressure. | Injection speed, pressure, shot size |

| Cooling | Plastic solidifies within the mold, taking its shape. | Cooling time, coolant temperature |

| Ejection | Mold opens, and the finished part is removed from the cavity. | Ejector system design, part release |

This entire cycle can take anywhere from a few seconds to a couple of minutes, depending on the part size, complexity, and material.

How do injection molds work in manufacturing?

We’ve discussed the process, but what about the star of the show – the injection mold itself? It might seem like just a metal block, but its inner workings are crucial and quite clever. Understanding how it functions is key to understanding injection molding.

An injection mold works by providing a precisely shaped cavity into which molten material is injected. It typically consists of two main halves: the cavity side (A-side) and the core side (B-side). These halves meet to form the part’s shape, and the mold also includes systems for material flow, cooling, and part ejection.

The injection mold is the heart of the injection molding process. It’s a highly engineered tool, usually made from hardened steel, aluminum, or beryllium-copper alloy. Its design directly impacts the quality of the final part and the efficiency of production.

The Two Halves: Cavity and Core

A mold is typically constructed in two main halves.

- Cavity (A-Side): This is often the stationary half of the mold, mounted on the fixed platen of the injection molding machine. It usually forms the exterior, more cosmetic surface of the plastic part. The molten plastic is injected through this side.

- Core (B-Side): This is usually the moving half of the mold, mounted on the movable platen. It forms the internal features of the part and often houses the ejection system.

When the mold closes, the space created between the cavity and the core defines the shape of the part. I remember the first time I saw a complex mold opened up; the intricate details of the core and cavity were amazing.

Material Delivery System

The mold needs a pathway for the molten plastic to travel from the machine’s nozzle into the part cavity. This system includes:

- Sprue: The main channel that receives molten plastic from the nozzle.

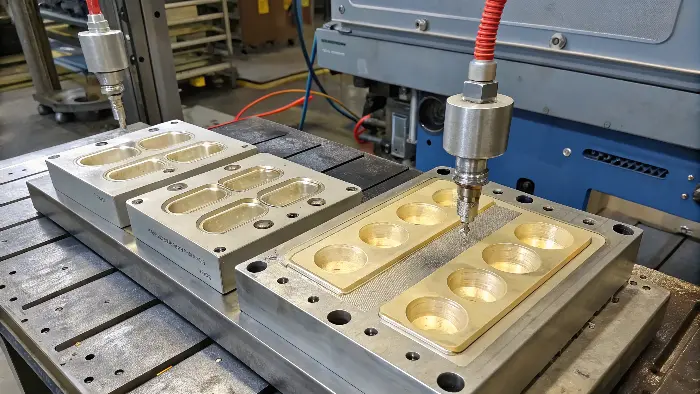

- Runners: Channels that distribute the plastic from the sprue to the individual cavities (if it’s a multi-cavity mold making several parts at once).

- Gates: The small openings where the plastic actually enters the part cavity. The design and location of gates are critical for proper filling, part appearance, and ease of removal from the runner system.

Cooling System

As we’ve mentioned, cooling is vital. Molds have channels drilled through them, strategically placed near the cavity and core surfaces. A cooling fluid, usually water, circulates through these channels to absorb heat from the molten plastic, causing it to solidify. Efficient cooling shortens the cycle time and helps ensure dimensional stability of the part.

Ejection System

Once the part has solidified, it needs to be removed from the mold. This is the job of the ejection system. Most commonly, ejector pins are located in the core half. When the mold opens, these pins push forward to eject the part. Other methods include stripper plates for parts with large surface areas or air ejection.

| Mold Component | Function | Importance |

|---|---|---|

| Cavity (A-Side) | Forms one side of the part, often the cosmetic exterior. | Defines part shape and surface finish. |

| Core (B-Side) | Forms the other side of the part, often internal features. | Defines internal geometry, supports ejection. |

| Runner System | Channels molten plastic from the sprue to the gates. | Ensures even filling of cavities. |

| Gate | Point of entry for plastic into the cavity. | Affects part quality, appearance, and de-gating. |

| Cooling Channels | Circulate fluid to cool the mold and solidify the plastic. | Controls cycle time and part dimensional stability. |

| Ejection System | Pushes the solidified part out of the mold. | Enables automated and damage-free part removal. |

The design and construction of an injection mold are complex and require specialized knowledge. A well-designed and well-maintained mold is essential for producing high-quality parts consistently and efficiently.

What type of manufacturing technology is injection molding described as?

So, where does injection molding fit into the bigger world of manufacturing? It’s a powerful technique, but just calling it "making stuff" doesn’t quite capture its specific role. Let’s define what kind of manufacturing technology it truly is.

Injection molding is primarily described as a mass production forming technology. It’s a "forming" process because it shapes raw material into a desired form without removing material (unlike machining). It’s "mass production" because it’s highly efficient for creating large quantities of identical parts at low unit costs.

Understanding how injection molding is classified helps us see its strengths and where it’s best applied. It’s not just one thing; it fits into several important manufacturing categories.

Forming Process

Manufacturing processes can be broadly grouped. Injection molding is a forming process (also sometimes called a shaping process). This means it takes a raw material (plastic pellets) and changes its shape by forcing it into a mold under heat and pressure. This is fundamentally different from subtractive processes like CNC machining, where you start with a larger block of material and cut away unwanted portions to achieve the final shape. It’s also distinct from additive processes like 3D printing (additive manufacturing), which build parts layer by layer from nothing.

Mass Production Technology

The most significant classification for injection molding is as a mass production technology. While the initial investment in creating a high-quality mold can be substantial, the cost per part becomes very low when producing thousands, hundreds of thousands, or even millions of units. The cycle times are typically very fast, often ranging from a few seconds to a minute or two. This high speed and efficiency make it ideal for products that require large volumes. I’ve worked on projects where millions of parts were needed, and injection molding was the only practical choice.

Net-Shape or Near-Net-Shape Manufacturing

Injection molding is often considered a net-shape or near-net-shape process. This means that the parts produced come out of the mold very close to their final, desired dimensions and surface finish. Little to no secondary machining or finishing operations are usually required. This minimizes material waste (apart from runners, which can often be reground and reused) and reduces overall production time and cost.

| Category | Injection Molding’s Classification | Reason |

|---|---|---|

| Material State | Forming/Shaping Process | Material is reshaped from a molten state to a solid part within a mold. |

| Production Volume | Mass Production Technology | High-speed cycles and low cost per part in large quantities. |

| Material Change | Transformation Process | Material changes state (solid to liquid to solid) and shape. |

| Final Shape | Net-Shape/Near-Net-Shape | Parts require minimal or no post-processing for their final form. |

So, when you think of injection molding, recognize it as a highly efficient way to shape plastics (and sometimes other materials like metals or ceramics with specialized versions of the process) into complex forms, especially when a large number of identical items are needed. It’s a cornerstone of modern manufacturing for a very good reason.

Conclusion

In summary, injection mold manufacturing is a vital technology that shapes our world by efficiently producing vast quantities of plastic parts. From understanding the core technology and its step-by-step process to how molds work and its classification as a mass production method, we’ve covered the essentials for you.