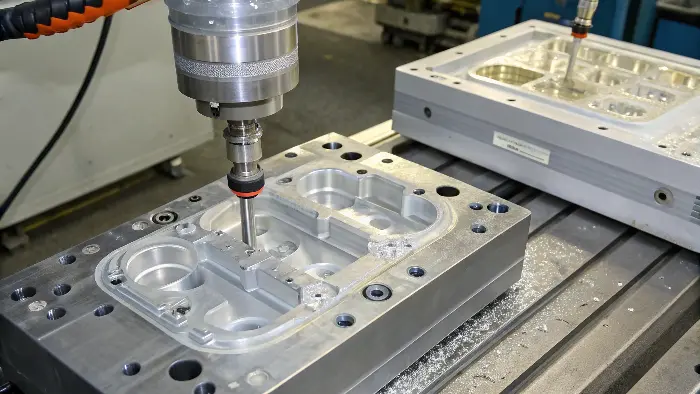

The operation of an injection mold remains unclear to numerous individuals. The fundamental understanding of this process enables people to recognize the manufacturing process behind common daily products.

A plastic injection mold works by providing a precisely machined cavity that forms the shape of the desired part. Molten plastic is forced into this cavity under high pressure. The mold then cools the plastic until it solidifies, after which the mold opens and the finished part is ejected.

Understanding the process is essential for anyone interested in product design, engineering, or manufacturing. In this article, we’ll break down the step-by-step workings of a plastic injection mold, highlighting the key components and stages involved.

How does plastic injection molding function?

Did you ever consider how all of the complex plastic pieces of your smartphone or automobile are made in huge quantities? The process may look daunting on the outside. If you’re attempting to wrap your brain around manufacturing today, understanding this is crucial.

Plastic injection molding is the process of pumping plastic material, usually pre-dried, into a machine where it is melted. The molten plastic is then injected under high pressure into a mold cavity that is closed. The plastic, within the mold, hardens and cools, taking the shape of the cavity, before being pushed out as a finished article.

Let’s break this down further into the main steps:

- Material Preparation: Often, plastic pellets need to be dried before molding. Moisture can cause defects in the final part, so this is an important first step. The dried pellets are then fed into the hopper of the injection molding machine.

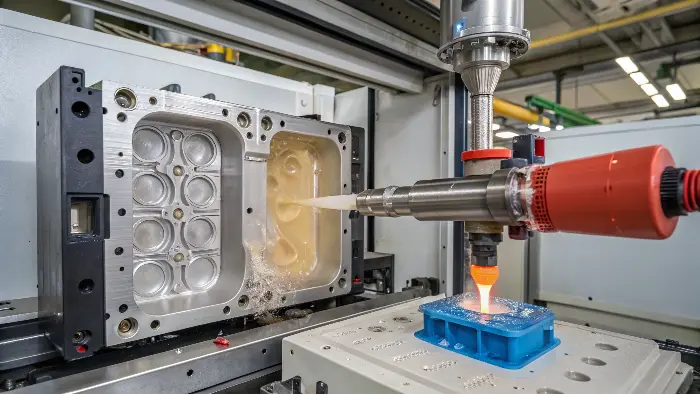

–Clamping: The injection molding machine has two main parts: the injection unit and the clamping unit. The clamping unit holds the mold. Before plastic is injected, the two halves of the mold are securely closed by the clamping unit. This unit must exert enough force to keep the mold shut against the high pressure of the incoming molten plastic. - Injection: The injection unit melts the plastic and forces it into the mold. We’ll talk more about melting soon. Once enough molten plastic is ready, it’s injected rapidly into the closed mold cavity.

- Cooling: Once the cavity is filled, the molten plastic starts to cool. The mold has internal cooling channels, usually circulating water, to help the plastic solidify quickly and take the shape of the mold. This cooling phase is often the longest part of the cycle.

- Ejection: After the component has cooled and hardened sufficiently, the clamping unit opens the mold. The ejection system, normally plates or pins, then pushes the finished component out of the mold.

All of this process—clamping, injecting, cooling, and ejecting—is referred to as the molding cycle. It continues to produce parts in quantity. It comes in handy for a designer like Jacky to know this so that he can design parts that are simple to mold, and it saves him money and time.

How is plastic melted in injection molding?

Do you want to know how an injection molding machine transforms solid plastic pellets into a hot, liquid that flows? Although the precise mechanism underlying this transformation may not always be evident, it is crucial. The entire process fails if the plastic is not melted properly.

The main methods of melting plastic in an injection molding machine are conductive heat from external heater bands wrapped around the barrel and frictional heat produced by a revolving screw. The screw conveys, compresses, and shears the plastic pellets, which creates most of the heat needed for melting.

Let’s take a closer look at what occurs:

Plastic is melted by a combination of pressure and heat in a barrel machine in the process of injection molding. This is how it is achieved:

The first step is the addition of plastic pellets to a container known as the hopper. Inside the hopper, the pellets are fed into a heated, long barrel with a reciprocating screw. While the screw rotates, it pushes the pellets forward along the barrel.

The plastic is melted by two processes: by the heat generated by electric heaters that encircle the barrel and by friction generated by the turning screw. The mixture of both heats up the pellets and melts them down to liquid, molten state.

The plastic is melted and molded at the leading edge of the screw. Once there is enough, the screw moves forward, forcing the melted plastic out through a nozzle into a cavity in a steel mold. The plastic solidifies, cools, and assumes the shape of the mold to create the final product.

The entire process is closely regulated in terms of temperature, pressure, and screw speed so that there is even melting and quality molded products. The average melting temperature also varies with the plastic material type to be employed, typically ranging between 160°C to 300°C.

What are the key injection molding Parameters?

Controlling and understanding important injection molding parameters is key to achieving high-quality production.

- Injection pressure is most critical, typically between 500 to 1500 bar, to ensure material flow and fill the mold.

- Mold temperature plays a significant role in part quality, with precise control required to maximize flow and cooling.

- Nozzle pressure is required for uniform material injection, and mold locking pressure ensures the integrity of the mold against injected material pressure.

- Recovery rate is what determines how fast the material is available for the next cycle, impacting manufacturing efficiency.

- Shrinkage rate is also an important parameter, which influences the size accuracy of the finished product.

- Clamping force keeps the mold shut up during processing to prevent defects.

- Screw speed affects material homogenization and injection stability.

Plastic injection molding is a highly efficient and precise manufacturing process that transforms plastic pellets into complex, high-quality parts. From feeding raw material into the hopper to melting it in the barrel and injecting it into a mold, every step is designed for accuracy, speed, and repeatability. This method is widely used across industries because it supports mass production, reduces material waste, and delivers consistent results with minimal manual labor.

What are the Different Injection Molding Types?

Below is a brief outline of the different types of injection molding applied in industry:

1. Thermoplastic Injection Molding

This is the most widely used injection molding process to date. It employs thermoplastic polymers that can be melted, formed, and cooled repeatedly without altering their chemical structure. ABS, polypropylene, and nylon are just some of the many materials employed in this process. This process is best suited for producing strong, light, and recyclable plastic parts utilized in everything from automotive parts to home products.

2. Silicone Injection Molding

Silicone injection molding uses liquid silicone rubber (LSR) instead of traditional plastics. It involves injecting two-part liquid silicone compound into a heated mold where it quickly cures. It is best suited for the manufacture of flexible, heat-resistant, and biocompatible products like medical devices, baby products, and cookware.

3. Metal Injection Molding (MIM)

This method is a mixture of powdered metallurgy and plastic injection molding technology. Metal powders of fine size are blended with binder plastic, injected into molds, and the binder is extracted and the part sintered at high temperature to obtain solid shape of metal. MIM is applied in manufacturing small and intricate metal components in aerospace, medical, and electronic sectors.

4. Rapid Injection Moulding

Speed and fast runs are emphasized by rapid injection molding. It’s often used for low-volume runs or prototyping. Molds can be built with aluminum rather than steel in order to reduce lead times and cost. The method allows for rapid testing and market validation before entering mass production.

5. Thermoset Injection Molding

With thermoset molding, thermosetting plastics are employed — plastics that become irreversibly hardened when they are heated and cannot be re-melted. The plastic is injected into a heated mold where the plastic irreversibly cures. The operation is ideally suited to parts requiring high temperature and chemical resistance, including electrical parts and automotive under-the-hood components.

How long does a plastic injection mold last?

This is a big question for anyone investing in tooling, as molds can be expensive. The lifespan of a mold isn’t fixed; it depends on many things.

A plastic injection mold’s lifespan can range from a few thousand shots for softer aluminum prototype molds up to over a million shots for hardened steel production molds.

Key factors influencing longevity include the mold material, the type of plastic being molded, design complexity, operating conditions, and the quality of maintenance.

Here are the main factors that determine how long a mold will last:

| Factor | Impact on Mold Lifespan |

|---|---|

| Mold Material | Aluminum: Softer, less expensive. Good for prototypes or low-volume (e.g., 5,000-50,000 shots). Wears faster. |

| Pre-Hardened Steel (e.g., P20): More durable than aluminum. Good for medium-volume (e.g., 50,000-500,000 shots). | |

| Hardened Tool Steel (e.g., H13, S7): Very hard and durable. Best for high-volume (e.g., 500,000 to 1,000,000+ shots). | |

| Part Material | Abrasive plastics (like those with glass fibers or certain flame retardants) will wear down the mold surfaces, especially gates and textured areas, much faster than non-abrasive plastics like polyethylene or polypropylene. |

| Mold Complexity & Design | Molds with very intricate details, sharp corners, thin sections, or complex actions (like slides or lifters) may experience wear or fatigue in those specific areas sooner than simpler molds. Tolerances also play a role; tighter tolerances mean less wear can be accommodated. |

| Operating Conditions | High injection pressures, fast cycle times, and extreme temperatures can put more stress on a mold, potentially shortening its life. Proper machine setup is key. |

| Maintenance | This is huge. Regular cleaning to remove plastic residue and gas deposits, proper lubrication of moving parts, careful handling, and correct storage can significantly extend a mold’s life. Neglect leads to premature failure. |

You can see well-maintained hardened steel molds that have produced millions of parts and are still going strong. Conversely, you may have experience of molds, even good quality ones, fail earlier than expected due to running abrasive materials without proper surface treatments or due to poor maintenance practices.

Choosing the right mold material based on expected production volume is a key decision to manage costs and ensure supply.

Conclusion

An advanced device called a plastic injection mold uses a cycle of injection, cooling, and ejection to precisely shape molten plastic. Anyone working in the plastic part manufacturing industry can benefit greatly from knowing how plastic melts, how the parts of a mold work together, and what affects a mold’s lifespan. This knowledge helps in making informed decisions from design to manufacturing.

If you’re in search of a reliable partner for plastic injection molding, think about collaborating with CKMold. Equipped with state-of-the-art machinery, a skilled engineering team, and a dedication to maintaining high standards, CKMold offers customized solutions for everything from prototype creation to large-scale manufacturing.

Whether your needs lie in mold design or substantial production runs, CKMold is prepared to transform your plastic component concepts into reality with accuracy and dependability. Explore our website today for more information or to request a quote.