To produce complex components containing sensitive inserts out of thermoset plastics may be a tasking assignment. Those, although fragile, can be easily broken or out of position in the case of a standard compression molding but might not be ideal using other techniques with the material used. This can result into disappointed redraws, redraw rates, and compromises you want to avoid. Transfer molding gives another intelligent answer, it is accurate and delicate on these very occasions.

Transfer mold is an apparatus used in a manufacturing process where a thermoset plastic or rubber part is first softened with heat in a separate chamber known as a "pot." Then the softened part is forced by a plunger through channels, referred to as sprues and runners, into a completely closed mold cavity. This is a blend of the closed-mold advantage of injection molding and the pressure application of compression molding and is particularly suited to the manufacture of intricate parts and to plasticating plastic around delicate inserts such as metal pins or electrical parts.

Material used for Transfer Molding

A thermoset polymer is the most frequently used material in transfer molding. This kind of polymer can be molded and manipulated easily, but when it is cured, it becomes permanent.In simple homogeneous transfer molded parts, the part itself is just this plastic substrate.

Conversely, resin transfer molding enables the creation of a composite material by inserting a fiber in the mold and then injecting the thermosetting polymer

The first step would be in having the basic understanding of this definition. However to really utilize this process, you must venture further. What is its step by step process? What is its comparison with more popular compression molding? It is the answer to these questions which makes a good designer a great designer. Here is what we are going to discuss, and you can be very comfortable in making the decision to use or not to use transfer molding in your next project.

What is the difference between transfer mold and compression mold?

At first glance, transfer and compression molding is very similar. Both involve the use of heat and pressure in shaping thermoset materials and one finds it hard to distinguish between the two. Selecting an incorrect one can be a combination of expensive mistakes that results into defective parts, destroyed inserts or even inefficient production run that wastes both money and time. The good news is that there is one major distinction to be learnt and everything becomes clear.

The primary difference is where the plastic material is positioned prior to being molded. In compression molding, the material charge is loaded directly into the end mold cavity, and the mold closes over it. In transfer molding, the material starts in a different pot, and the material is only "transferred" into the cavity when the mold is nearly closed. This makes transfer molding much better suited for detailed parts and parts with delicate inserts since the material is allowed to flow over them softly and not be pushed by the closing mold.

This is one of the lessons I learned when attending a project with an automotive client. They should have a sensor housing which has some thinner and accurately-positioned brass pins. To reduce tooling costs we initially quoted a compression mold. Its first experimental run was a failure and the closing pressure of the press broke almost 40 percent of the pins. We were forced to recast the tool in the role of transfer mold. The initial capital was bigger and the scrap rate was almost zero. It made it clear that by selecting the right process initially, one saves a lot of money in the future.

Key Distinctions for Designers

Let’s break down the practical differences that will impact your design decisions.

Part and Mold Complexity

A compression mold is essentially an easy simple one a hole made by two-piece tool is in general. A transfer mold is more complicated. It needs an additional part, the transfer pot, a plunger and a set of runners in order to transfer the material in the pot to the cavities. Such added complexity implies that transfer molds cost more to design and construct.

Suitability for Inserts and Intricate Shapes

This is where transfer molding really shines. Since the mold is closed prior to the material flowing in, whatever inserts you’ve put into the cavity are held firmly in place. The plastic flow surrounds them gently. This makes it possible to produce very fine parts and the successful overmolding of electronics, pins, and connectors. Compression molding is most suited for simpler, heavier shapes with no fine internal details.

Material Waste and Cycle

In transfer molding, there is always a little cured material remaining in the pot (the "cull") and in the runners. Because thermosets cannot be recycled, this is purely waste. Compression molding, on the other hand, creates very little waste. Transfer molding can, sometimes, occasionally provide quicker cycle times for multi-cavity tools because the single large charge in the pot can be more evenly heated and transferred more quickly than filling many small charges into individual compression cavities.

| Feature | Transfer Molding | Compression Molding |

|---|---|---|

| Material Placement | In a separate "pot" outside the cavity | Directly inside the mold cavity |

| Mold Status During Flow | Closed | Open, closes on the material |

| Best for Inserts? | Yes, excellent | No, high risk of damage |

| Part Complexity | High, intricate shapes | Low to medium, bulkier shapes |

| Tooling Cost | Higher | Lower |

| Material Waste | Higher (cull and runners) | Very Low |

What are the disadvantages of transfer molding?

Having been educated on how great transfer molding is for intricate parts, it’s easy to think it’s the greatest thing for every thermoset application. But diving in blind without knowing the downsides can introduce some unpleasant surprises. You might be faced with higher-than-anticipated tooling costs, struggle with material loss, or find that the process is less efficient than you had hoped, and all of these can hurt your project budget and timeline.

The major drawbacks of transfer molding are higher material scrap, more expensive and more complex tooling, and potentially longer cycle times than compression molding. The cull, or remaining material in the transfer pot and runners that is cured and not reusable, is another drawback. The complexity of the mold and its pot and runner system also contributes to manufacturing and maintenance costs.

It is essential to put into balance these shortcomings, and advantages. I also was in a high volume part in which the actual material cost was very high. The amount of wasted material to a cull and runners using transfer molding is growing in each and every shot and the price of the utilized material was beginning to leave us with an impressive bill. Extra time and money were involved to optimize the runner system to minimize the wastes as much as possible. It is a trade-off you need to take into account already at the very beginning.

Advantages of Transfer Molding

There are a number of advantages of transfer molding. It has greater tolerances than, say, compression molding. This is because transfer molding employs greater pressure than compression molding. Both kinds of molding processes require pressurized raw material. In compression molding and transfer molding, the raw material is pressurized when it is injected into the mold cavity. Transfer molding, however, exerts greater pressure on the raw material, thus enabling greater dimensional tolerances.

Transfer molding is also rapid. Transfer molding is less time consuming when compared to other molding processes. The raw material in compression molding does not need to be fully liquid, it can be semi-solid. The plunger is able to inject or otherwise force the semi-solid raw material into the mold cavity. This increases the speed of transfer molding compared to most other molding processes, especially those that can only accommodate liquified material.

Transfer molding also has variations. Among the various variations, there are resin transfer molding, vacuum-assisted resin transfer molding and micro transfer molding. Between these various variations, there are nuances. However, all of them can be regarded as a form of transfer molding.

A Closer Look at the Drawbacks

Let’s break down these disadvantages so you can anticipate and plan for them.

Inevitable Material Waste

As indicated, the largest economic liability is the waste. The biscuit of cured material remaining in the transfer pot, after the plunger has been at work, is called the cull. This, together with the sprue material and runners is a part and parcel of the process. As thermosets have a chemical change that is also irreversible (curing), this residual cannot be reground and reused as in a thermoplastic. It causes one to lose raw material at every cycle, and it can be serious when costly compounds are involved.

Higher Tooling and Maintenance Costs

A transfer mold is not a simple tool. It has more moving parts and more intricate features than a compression mold.

- Complexity: Designing and machining the pot, plunger, and runner system requires more time and precision, driving up the initial tooling investment.

- Maintenance: These channels and the pot need to be cleaned regularly to prevent material buildup, which can affect part quality. Wear and tear on the plunger and pot are also concerns that add to the long-term maintenance costs.

Process Limitations

Though flexible, transfer molding has limitations.

- Cycle Times: Charging the charge, mold closure, material transfer, and curing could in certain cases take more than a simple, direct compression cycle, especially for single-cavity molds.

- Part Size: The process is best suited for small- to mid-size parts. The cost of equipment and material for very large parts makes the process unaffordable and impractical compared to compression or other molding processes.

| Disadvantage | Why it Happens | How to Mitigate It |

|---|---|---|

| Material Waste | The process requires a cull and runner system. | Optimize runner design; use multi-cavity molds to improve the ratio of part volume to waste volume. |

| High Tooling Cost | Molds are more complex (pot, plunger, runners). | Carefully evaluate if the part complexity truly requires transfer molding. |

| Longer Cycle Times | Multi-step process (load, transfer, cure). | Use plunger molding for faster injection; optimize pre-heating of the material charge. |

| Higher Maintenance | More components to clean and service. | Design the mold for easy access to the pot and runners; use durable tool steels. |

Which of the following is a type of transfer moulding?

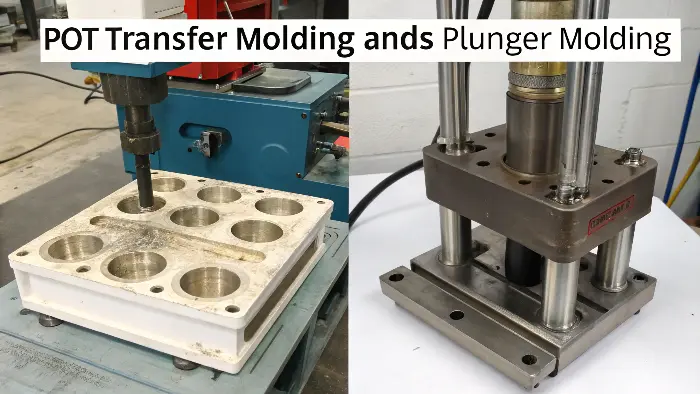

Your really getting to know your transfer molding, when you may overhear engineers or toolmakers talking about pot transfer and plunger molding. Are they different names of the same thing or are they different processes? A lack of knowledge of these differences may place you at a disadvantage whereby you may struggle to express your needs or even to know the kind of equipment that you definitely need in your work.

The two major transfer molding methods are pot transfer molding and plunger molding. They employ the same principle of material transfer from pot to cavity but with varied method of actuating the plunger. In pot transfer, the plunger is integral to the mold and actuated by the main press action. In plunger molding, the plunger consists of an independent hydraulic ram on the molding press, with much greater control of the process.

The tendency to define the correct process according to high-precision jobs depends on this difference. As an illustration, microchip encapsulation, where fragile microchips are encapsulated (and thus called semiconductor packaging), virtually exclusively depends on plunger molding. This fine regulation of speed and pressure provided by the auxiliary ram is necessary to prevent damaging the fine delicate wire bonds within the chip. Pot transfer would just not be that delicate.

Pot Transfer vs. Plunger Molding

Let’s look at these two methods side-by-side to see how they work and where they are best used.

Pot Transfer Molding

This is the more traditional and less mechanically sophisticated of the two models.

- Operation: The mold is typically a three-plate setup. Charge material is filled in the pot, which is part of the center plate. When the main press closes, a plunger connected to the top plate falls into the pot, pressing the material through the runners into the cavities of the bottom plates. Rate of closure of the press is functionally related to force and transfer rate.

- Benefits: May be applied using a standard, simple compression press without the requirement for any extra hydraulic cylinder. The mold is contained within itself.

- Cons: Offers very minimal regulation of transfer rate and pressure. It is a "one-speed" operation that is press-controlled.

. Plunger Molding (or Auxiliary Ram Transfer Molding)

This is a more detailed and specific description of the process.

- How it works: The mold is usually a less complicated two-plate mold. The magic lies in the press itself, which has a separate, smaller hydraulic cylinder on top (the auxiliary ram or plunger). Once the main press closes the mold, the plunger is driven independently to drive the material from the pot into the cavities.

- Benefits: Allows precise, independent control of transfer speed, pressure, and timing. This produces higher quality parts, better consistency, and is required with sensitive applications.

- Benefits: Does not require a higher and more expensive transfer molding press with an auxiliary ram.

| Feature | Pot Transfer Molding | Plunger Molding |

|---|---|---|

| Actuation | Main press closing action | Separate hydraulic plunger on the press |

| Control | Limited; tied to press speed | High; independent control of speed & pressure |

| Press Type | Standard compression press | Specialized transfer press with auxiliary ram |

| Mold Design | More complex (often 3-plate) | Simpler (often 2-plate) |

| Best For | General-purpose, less critical parts | High-precision, delicate parts (e.g., electronics) |

| Consistency | Good | Excellent |

Conclusion

Transfer molding is a very strong process that intelligently fills the gap between compression moulding and injection moulding. It is the ultimate method to produce intricate thermoset/rubber components, particularly those that need the careful inlay of inserts that need the process of encapsulating inserts. Now that you know the essence of its process, its key factors of differences with compression molding, the possible drawbacks attached with it such as, wasting of material, and its specific types such as, pot and plunger molding, you now have a complete set of knowledge needed to help you make more knowledgeable design and production decisions.