When you’re working on an injection molding project, getting the shot weight right can make or break your results. Many designers and engineers struggle with this calculation, leading to wasted material, poor part quality, or even costly mold damage. If you’ve ever felt unsure about how to calculate shot weight, you’re not alone.

To calculate shot weight in injection molding, you need to multiply the volume of the molded part (including runners and sprues) by the material’s density. This gives you the total weight of plastic needed for one shot, ensuring you choose the right machine and avoid defects.

Understanding shot weight is the first step to mastering injection molding. If you want to avoid production headaches and keep your projects on track, it’s important to know not just the formula, but also how to apply it in real-world scenarios. Let’s break down the details and see how you can use this knowledge to improve your work.

What is the formula for shot weight in injection molding?

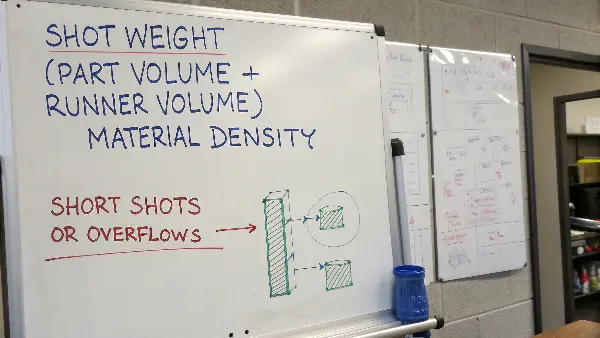

Many people get stuck when they try to figure out the exact formula for shot weight. They might guess or use rough estimates, which can lead to problems like short shots or overflows. I’ve seen this happen in my own projects, and it’s always better to use a clear, reliable method.

The formula for shot weight in injection molding is: Shot Weight = (Part Volume + Runner Volume) × Material Density. This calculation ensures you have enough material for each cycle, including the part and the runner system.

Let’s dive deeper into each part of the formula. First, you need to measure the volume of your molded part. This is usually given in cubic centimeters (cm³) or cubic millimeters (mm³). Don’t forget to include the volume of the runners and sprues, as these are filled with plastic during each shot. Next, you need the density of your chosen material, which is usually listed in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). Multiply the total volume by the density, and you have your shot weight.

Here’s a simple table to help you visualize the process:

| Step | What to Do | Units |

|---|---|---|

| 1. Part Volume | Measure or calculate part volume | cm³ or mm³ |

| 2. Runner Volume | Measure or calculate runner/sprue volume | cm³ or mm³ |

| 3. Total Volume | Add part and runner volumes | cm³ or mm³ |

| 4. Material Density | Find material density from datasheet | g/cm³ |

| 5. Shot Weight | Multiply total volume by density | grams |

For example, if your part and runner volume add up to 50 cm³, and your material density is 1.05 g/cm³, your shot weight is 52.5 grams. This method works for any thermoplastic material and helps you avoid surprises during production.

How do you calculate injection molding?

Calculating injection molding parameters goes beyond just shot weight. You need to consider several factors to ensure a successful molding process. I remember a project where I overlooked one small detail, and it led to a week of troubleshooting. That’s why I always double-check my calculations.

To calculate injection molding, you need to determine the shot weight, select the right machine with enough injection capacity, and set the correct processing parameters like temperature, pressure, and cycle time. Each step ensures your part is molded accurately and efficiently.

Let’s break down the main calculations involved in injection molding:

1. Shot Weight Calculation

As discussed, use the formula:

Shot Weight = (Part Volume + Runner Volume) × Material Density

2. Machine Selection

Check the machine’s maximum shot capacity. The shot weight should be between 30% and 80% of the machine’s rated shot size for best results.

| Machine Shot Size | Recommended Shot Weight Range |

|---|---|

| 100 grams | 30–80 grams |

| 200 grams | 60–160 grams |

3. Processing Parameters

Set the melt temperature, injection pressure, and cycle time based on the material’s datasheet and part design.

4. Mold Filling Analysis

Use simulation software or experience to predict how the mold will fill. Adjust gate size, runner layout, and venting as needed.

By following these steps, you can avoid common pitfalls like short shots, flash, or warping. Each calculation builds on the last, so accuracy at every stage is key.

How to calculate injection capacity?

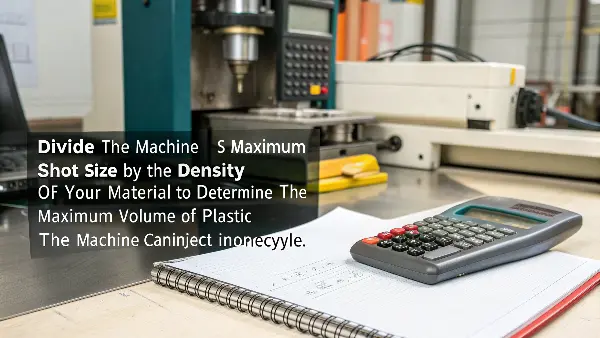

Injection capacity is a critical factor when choosing an injection molding machine. If you pick a machine that’s too small, you risk incomplete parts. If it’s too large, you waste energy and money. I’ve learned to always check this before starting a new project.

To calculate injection capacity, divide the machine’s maximum shot size (in grams or ounces) by the density of your material. This tells you the maximum volume of plastic the machine can inject in one cycle, helping you match the machine to your part.

Let’s look at this in more detail. Injection molding machines are rated by shot size, usually in grams or ounces of general-purpose polystyrene (GPPS). But different plastics have different densities. To find the actual volume the machine can inject, use this formula:

Injection Capacity (cm³) = Machine Shot Size (grams) ÷ Material Density (g/cm³)

For example, if your machine has a shot size of 200 grams, and your material has a density of 1.2 g/cm³:

Injection Capacity = 200 ÷ 1.2 = 166.7 cm³

Now, compare this to your calculated shot volume (part + runner). Your shot volume should be between 30% and 80% of the machine’s capacity for stable production. Here’s a quick reference table:

| Machine Shot Size (g) | Material Density (g/cm³) | Injection Capacity (cm³) | Recommended Shot Volume (cm³) |

|---|---|---|---|

| 100 | 1.0 | 100 | 30–80 |

| 200 | 1.2 | 166.7 | 50–133 |

| 300 | 1.05 | 285.7 | 85–229 |

This calculation helps you avoid problems like incomplete filling or excessive residence time, which can degrade the material.

What is shot weight in casting?

Shot weight is a term used in both injection molding and casting, but it means slightly different things depending on the process. I’ve worked on both types of projects, and knowing the difference can help you avoid confusion.

In casting, shot weight refers to the total weight of molten material injected or poured into the mold to form a single part, including any runners or gates. It’s similar to injection molding, but the materials and processes can differ.

Let’s explore the similarities and differences between shot weight in injection molding and casting:

Shot Weight in Injection Molding vs. Casting

| Aspect | Injection Molding | Casting |

|---|---|---|

| Material | Thermoplastics, some thermosets | Metals, alloys, some plastics |

| Process | High pressure injection | Gravity or low pressure pouring/inject. |

| Shot Weight Includes | Part + runner + sprue | Part + runner + gate |

| Importance | Machine selection, quality control | Material planning, mold filling |

In both cases, accurate shot weight calculation ensures you have enough material to fill the mold and produce a quality part. In casting, shot weight also helps you plan for material costs and melting requirements.

Conclusion

Calculating shot weight is a key skill in injection molding and casting. By using the right formulas and understanding the process, you can choose the right machine, avoid defects, and keep your projects running smoothly. Mastering these calculations will help you deliver better results and grow your expertise in the field.