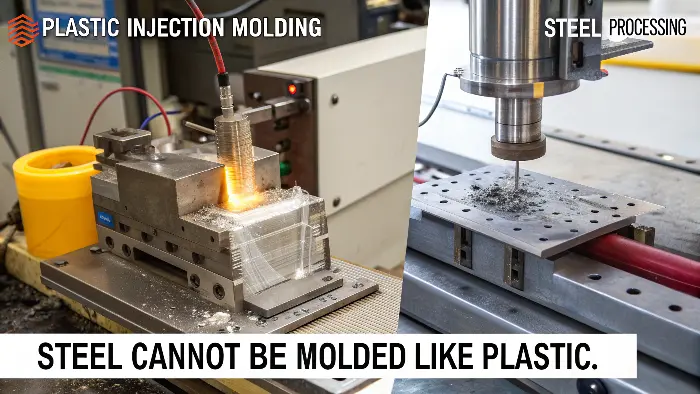

You are a designer and you have ever wondered why we cannot just exchange our plastic pellets with steel and recycle the method? It appears that it would dole out a universe of possibilities. The truth of the matter is any attempt at making steel act like plastic would be disastrous. It is not only inefficient to disregard the huge differences but also impossible. Behind the scenes is a major aspect in grasping the two materials.

The main reason of difficulty in the molding of steel is mainly by its varying melting point and material properties compared to plastic. Plastic will melt at a few hundred degrees, whereas steel cannot melt at all unless heat is applied in thousands. This excessive heat would annihilate a customary plastic injection mold Moreover, molten steel does not behave the way a molten plastic substance does; it demands special techniques such as casting, forging or metal injection molding (MIM), which process excessive heat and pressure differently. The inherent physical Chemistry of the materials determines quite different methods of production.

This basic difference in temperature is only the tip of the iceberg. Everything including the mold material as well as the process is affected. To get a better handle on this we have to examine the difficulties in dealing with steel, a little further. It is not only increasing the heat it is a new ball game altogether Then we will dig into the details as to why steel forming is such a special case and specifically how it compares to the plastic molding solutions you already know.

Is steel hard to mold?

You have made a complicated component and this customer desires it as steel because it is strong. But the techniques of molding you are familiar with cannot be used here, you see: You are working on the material that is not easy to form and your design goals appear to be unattainable. Steel is not easy to manufacture because the heat and enormous pressures it endures are enough to give nightmares. Tooling becomes rapidly worn out and the costs spiral. It is not impossible though, with the correct strategy.

Steel is much tougher to shape compared with plastics. The high melting temperature of its elements (~1500 o C / ~2750 o F) necessitates specialty, heat-resistant tooling and furnaces. Hot, molten steel is less fluid than molten plastic; hence difficult to use to fill complex mold cavities. The use of processes, such as casting, forging and metal injection molding (MIM), each come with their own complexity in terms of pressure, cooling rates, and possible defects of porosity or contractions. The input of the energy and equipment is much greater.

Talking about the "molding" of steel, in fact, we speak about the family of processes, which bear no resemblance to the process of plastic injection molding. I can recall a client who wanted a tiny, gear-type piece. They also required the strength of steel, and the part had fine teeth which could not be very cheaply machined. We would have to select the proper "molding." This involved the consideration of more than just filling a hole and really studying what steel meant.

The Challenge of Temperature

The most obvious obstacle is heat. Your average P20 or H13 tool steel, the workhorses of plastic injection molds, will melt if you try to fill them with liquid steel. The processes used to mold steel need to consider temperatures that can boil other metals.

- Sand Casting: Involves molds of sand, which are heat-resistant but are used once and then destroyed.

- Investment Casting: A heat-resistant ceramic mold, which is temporary and used once.

- Forging: Doesn’t melt the steel entirely, but they heat it so that it becomes pliable and requires large presses to shape it.

The Problem with Flow (Viscosity)

When hot, steel does not flow very readily. Harry Please imagine it not so much like water as very thick, heavy lava. This viscosity is very high, which makes it hard to fill small-walled etc. or represent sharp contours and small details. This is one of key design constraints Whereas in plastic molding your concern may be 0.5mm in wall thickness, in steel casting, this would be practically impossible to fill reliably. That is why the majority of cast steel parts appear to be bulky or over-proportioned with fat radii; the design has to take into account the flow of material.

Comparing Steel Forming Processes

Choosing the right method depends on a trade-off between cost, precision, strength, and volume. For that client with the small gear, we ended up going with Metal Injection Molding (MIM). It was the only way to get the net-shape complexity they needed without expensive secondary machining.

| Process | Description | Key Advantages | Key Disadvantages |

|---|---|---|---|

| Sand Casting | Pouring molten steel into a sand mold. | Low cost for large parts, complex shapes possible. | Poor surface finish, low dimensional accuracy. |

| Investment Casting | Using a wax pattern to create a ceramic mold. | Excellent surface finish, high accuracy, complex parts. | Higher cost, more steps, size limitations. |

| Forging | Shaping steel using compressive forces (hammering/pressing). | Superior strength and durability due to grain structure. | Less complex shapes, requires secondary machining. |

| Metal Injection Molding (MIM) | Mixing fine metal powder with a binder to create a feedstock, then injection molding and sintering. | High complexity, excellent accuracy for small parts. | High tooling cost, limited to smaller parts, binder removal adds steps. |

What is the essential performance of plastic mold steel?

The characteristics and attributes that make plastic mold steel appropriate for producing plastic molds used in extrusion, blow molding, injection molding, and other plastic forming processes are primarily referred to as its essential performance. These steels are specifically made to withstand the extreme temperatures, pressures, and wears associated with the manufacturing of plastic. The following are the main performance factors:

1. High strength and hardness

For plastic mold steel to endure repeated pressure from the injection molding process, it must be sufficiently hard. High strength guarantees that even under extreme stress, the mold will keep its precise shape.

2. Strong Toughness

During production, toughness keeps the mold from chipping and shattering. Toughness is essential to prevent abrupt failure since molds frequently undergo cycles of heating, cooling, and pressure.

3. Strong Toughness

During production, toughness keeps the mold from chipping and shattering. Toughness is essential to prevent abrupt failure since molds frequently undergo cycles of heating, cooling, and pressure.

4. Resistance to Corrosion

Certain plastics can harm mold surfaces by releasing corrosive gasses during processing (such as PVC, which produces HCl). High-corrosion-resistant mold steel prolongs its useful life by preventing rusting and deterioration.

5. Stability and Thermal Conductivity

Repeated cycles of heating and cooling are applied to plastic molds. A homogeneous temperature distribution made possible by good thermal conductivity lowers the number of flaws in plastic components. Long-term use of the mold is guaranteed to preserve its dimensional correctness thanks to its high thermal stability.

The essential properties of plastic mold steel include hardness, toughness, wear resistance, corrosion resistance, thermal stability, and excellent machinability, which collectively ensure durability, precision, and cost-effectiveness in mold manufacturing.

Can you pour plastic into a mold?

You submit your CAD online to have a plastic part created and a few weeks later a finished object showed up. But what is the actual going on in between? It can be quite introvert similar to a black box process Lacking the knowledge of the principles of plastic filling a mould can cause manufacturing errors such as sinks, weld lines, and short shots. These defects may result in rework and loss of production time which is expensive. Unwraveling the process Let us understand it in common language

The most common industrial process uses injection molding, which is much more of an injection than a pour. During the process, plastic pellets are liquidized and currently injected under high pressure forcefully into a closed in a two-part mold cavity made of steel. It is this pressure that allows the molten plastic to fill in all details of the mold prior to cooling and solidifying into the finished part. Colloquially less elaborate gravity-pouring techniques, called casting, apply to some plastics as well.

The word "pour" is a bit mild when what occurs actually happens. The injection molding equipment is unforgiving and of high speed, pressure and intense. I have designed one thin walled enclosure in electronics. Initial shot groups were not complete: the plastic would solidify before it could fill the whole mold. We did not require any modifications in the design, just substantially greater injection speed and injection pressure. It is a very strong reminder that this is not simply a matter of accomplishing a task that is placing a bucket of water; it is managing a dynamic happening.

The Injection Molding Cycle Explained

To understand the process, you must study its separate steps. It is a repeatable, accurate process that takes place very quickly, at times in a few seconds.

- Clamping: The two steel mold halves are clamped together by huge pressure using the hydraulic or electric clamp of the molding machine. The pressure applied must be strong enough to withstand approaching injection pressure.

- Injection: A screw within a hot barrel forces molten plastic ahead, injecting it into the mold cavity at pressure and high speed.

- Dwelling (Packing): After the cavity is almost filled, there is pressure applied. This "packing" pressure forces additional material in to compensate for shrink when the plastic sets. This helps prevent sink marks.

- Cooling: Cooling channels are present in the mold. Water flows through these channels to cool the plastic component until it reaches a solid state to be pushed out. This is usually the longest segment of the cycle.

- Opening of Mold: The two mold halves open and the clamp releases.

- Ejection: Ejection pins push the finished part out from the mold.

Pressure: The Unsung Hero

The designer will concentrate on the part form, however, the molder is concerned with pressure. Pressure is used to inject the part, and packing pressure to perfect it. Lack of sufficient packing pressure leaves you with sink marks and voids. Too little and you may not cleanly flash the mold (where you have plastic bleeding at the parting line) or overstress the part. It is important to know that your design will be put under tens of thousands of PSI.

Beyond Injection: Other Plastic Molding Methods

While injection molding is king for high-volume, solid parts, it’s not the only way to shape plastic. Different part requirements call for different methods.

| Method | Description | Common Use Case |

|---|---|---|

| Injection Molding | High-pressure injection of molten plastic into a steel mold. | High-volume, complex parts (e.g., electronics casings, gears). |

| Rotational Molding | Plastic powder is heated and rotated in a mold to coat the walls. | Large, hollow parts (e.g., water tanks, kayaks, playground slides). |

| Blow Molding | A parison (tube of hot plastic) is inflated into a mold cavity. | Hollow parts with thin walls (e.g., bottles, containers). |

| Thermoforming | A heated plastic sheet is stretched over a mold. | Packaging (blister packs), trays, and simple enclosures. |

What is a P20 mold steel?

One of the most often used materials for die-casting dies, plastic molds, and other tooling components is P20 mold steel. This alloy steel is pre-hardened and offers a great mix of toughness, hardness, and machinability. P20 steel is commonly supplied pre-hardened, often at 28 to 34 HRC, so it doesn’t need to be heat-treated further before being used to make molds. For mold makers, this characteristic makes it an economical and time-saving option.

Carbon, chromium, molybdenum, manganese, nickel, and silicon are all present in P20 mold steel in certain amounts.

Carbon, chromium, molybdenum, manganese, nickel, and silicon are all present in P20 mold steel in certain amounts. These alloying elements give it good strength, uniform hardness across large sections, and resistance to cracking during high-pressure molding operations. Another advantage of P20 steel is its ability to be polished to a very fine finish, which is particularly useful when producing molds for transparent plastic products like lenses, bottles, or cosmetic packaging

In the plastics sector, P20 steel is frequently used to create die-casting dies, blow molds, and injection molds. In particular, the automobile, consumer products, and packaging industries use it for press tools and extrusion dies. Large molds and complex parts can both benefit from its hardness and machinability, which enables producers to create accurate and long-lasting tooling.

P20 mold steel does, however, have certain drawbacks despite its great benefits. Because of its comparatively lesser hardness in comparison to tool steels such as H13 or 718, it might not endure as long in production settings with exceptionally high volumes. Furthermore, P20 needs surface treatments like nitriding or chrome plating to increase its resistance to wear and corrosion when molding corrosive plastics like PVC.

Can mold penetrate steel?

You have plunked down tens of thousands of dollars in a hardened steel mold. You assume that it can withstand a million shots but what happens when the material you are injecting resumes to degrade it? Hidden conditions such as abrasion and corrosion can corrode your costly tooling over time. This creates parts out of spec, higher maintenance and ultimately, the untimely death of your mold, destroying the profitability of your project. So let us consider how this can be prevented.

No, plastic itself will not go in solid steel on a molecular basis. The wear and damage of steel mold during the molding process is an absolute possibility. Abrasive fills in plastics (such as glass fibers) may wear away at the mold surface, whereas the corrosive traces released by certain polymers (such as PVC) can chemically damage a mold. When high injection pressure is used it can also lead to mechanical fatigue of delicate mold features due to high injection pressure. Although it does not entail penetration, material interaction definitely impairs the mold.

I acquired this lesson at the wrong end of the stick early in my career. A client was insistent on standard P20 tool steel in a mold that was in use with a 30 percent glass-filled nylon. They wished to save on the tooling up-front cost. The mold was perfect out of the box but, after 50,000 cycles the parts began to stick and the surface was rough. The sand abrasive glass fibers had actually blasted the cavity surface through sand blasting. These "savings" on the tool steel were counterbalanced by the expense of continual repairing and frequent replacement. The plastic did not penetrate the steel but it definitely ruined it.

The Three Types of Mold Wear

Knowing the enemy is the beginning of beating the enemy. Mold wear is generally in three types:

- Abrasive Wear: It is mechanical wear due to hard fillers incorporated into the plastic. Glass fibers, carbon fibers, and even certain mineral fillers behave like sandpaper to wear down the steel with each shot, particularly in high-flow areas such as gates.

- Corrosive Wear: Certain plastics such as PVC emit corrosive gases (hydrochloric acid) when heated. The corrosive gases diffuse into the steel surface and result in rusting and pitting. Even flame retarder additives may result in the same corrosive effect.

- Adhesive Wear (Galling): This one is not as apparent. At elevated heat and pressure, small particles of the steel mold surface weld onto the plastic part at the microscopic level. When the part is forced out, it tears away these microscopic steel particles with a progressively rougher surface.

Material Choice Matters: Abrasive vs. Corrosive

The plastic you choose dictates the type of steel and protection your mold needs. You can’t use a one-size-fits-all approach.

| Plastic Type | Common Fillers | Wear Potential | Mitigation Strategy |

|---|---|---|---|

| Polypropylene (PP) | Talc, Calcium Carbonate | Low to Medium Abrasion | Standard hardened steel (P20). |

| Nylon (PA) | Glass Fiber (GF) | High Abrasion | Harder tool steel (H13), surface coatings (e.g., TiN). |

| PVC | None | High Corrosion | Stainless tool steel (e.g., S136/420SS), proper venting. |

| ABS | None | Low | Standard hardened steel (P20). |

Protecting Your Investment: Coatings and Maintenance

Against aggressive materials you must enhance your defense. This implies that selection of a higher strength tool steel at the outset (such as H13 against abrasion or S136 against corrosion) is the first principle. Add to this the availability of specialized surface coatings that have the capacity to increase the lifespan of a mold exponentially. A TiN coating (or Diamond-Like Carbon (DLC) coating) makes the surface ultra-hard, slick and resistant to both abrasion and adhesion. When added to the regimen of frequent cleaning and polishing, such measures will help to ensure that your mold remains intact throughout its projected lifecycle.

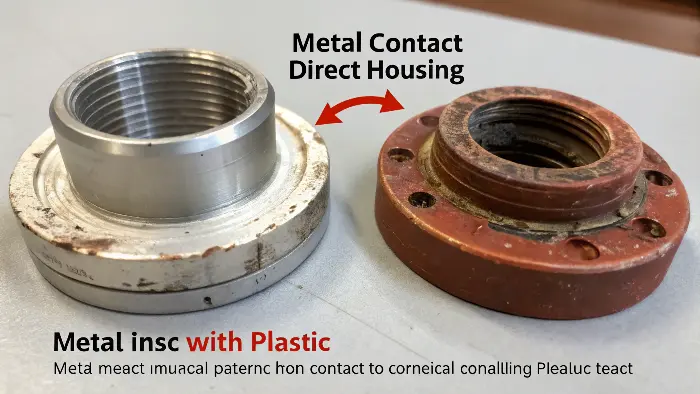

Can metal corrode plastic?

The geometry you have needs a metal insert or some other metal fastener against a plastic housing. You expect them to blend well together, but what if there is an anticipated chemistry inside one that is just waiting to occur? The plastic enveloping the metal may also crack over time, turn brittle or discolour. It is this random material degradation that may cause failure of the product, warrant claims and reputation damage to your company. The interaction is significant to the long-term reliability.

Metal usually does not oxidize plastic, in the classical sense of surface reactions. Metals however can sometimes be catalysts which hasten the chemical degradation of some plastics, in particular when exposed to elevated temperature or UV light. An example is that the copper and copper alloys may hasten the thermal oxidation of polymeric structures such as polypropylene. This is not a rusting of the plastic but a degradation brought about by metals and results in making it brittle and weak. The compatibility and material selection is hence very vital.

This is one of those sub tricky which can ambush a designer. I was once engaged in the product recall of a hot water appliance. The pieces had brass fitting that came in direct contact with a polypropylene housing. After rough service of about a year these housings began to crack and leak, just about the brass fittings. The presence of the brass alone was good, but its addition along with the heat greatly sped up the disintegration of the PP polymer chains, making it very brittle. It is an exemplary situation of how the metal does not corrode plastic, but it can help destroy it perfectly.

Catalytic Degradation: The Real Threat

The chemical term used to describe this occurrence is catalytic degradation. There is no consumption of the metal itself in the reaction, but its ions interfere with the chemical bonds of the polymer. This hurry up the process of natural ageing of the plastic which, already, is being corroded by various factors; the oxygen, the heat, and the UV rays. The metal does no more than step on the accelerator. This is the reason why a plastic component may be very stable in itself but when a certain metal component is inserted, then it loses stability.

Common Culprits: Metals and Plastics to Watch

Fortunately, this reaction is specific to certain material pairings. Knowing the bad combinations is half the battle. Copper and its alloys (brass, bronze) are the most common offenders.

| Plastic | Compatible Metals | Metals to Use with Caution | Reason for Caution |

|---|---|---|---|

| Polypropylene (PP) | Stainless Steel, Aluminum | Copper, Brass | Strong catalytic degradation, especially at elevated temperatures. |

| Acetal (POM) | Stainless Steel, Aluminum | Copper, Brass, Zinc | Very sensitive to catalytic degradation. Avoid direct contact. |

| Polycarbonate (PC) | Stainless Steel, Aluminum, Chrome Plating | N/A | Generally good compatibility, but sensitive to certain chemicals. |

| ABS | Most common metals | N/A | Generally robust and compatible with most metals. |

Designing for Compatibility

As a designer, you might have various methods of preventing this kind of failure.

- Select Compatible Materials: The easiest thing to do is refer to a compatibility chart and select a metal-plastic material that is widely known to be stable. Replacing brass with stainless steel is a widely used and effective solution.

- Use a Barrier: If you need to use an incompatible pair (for example, for electrical conductivity reasons), you can isolate them. Applying a non-reactive metal plating to the metal piece, such as nickel or chrome, provides a good barrier.

- Find a Stabilized Polymer: There exist certain grades of polymers from the majority of plastic manufacturers that have additives known as inhibitors. These inhibitors are designed to counteract the catalytic effect of metals, providing an added protection.

Conclusion

Steel and plastic molding are two different planets, driven by temperature and physics of materials. Steel is difficult to mold, requiring casting, or even more complicated techniques such as MIM, rather than injection molding. It is a high-stakes game of plastic molding where knowledge of the process can avoid defects. To achieve longevity, you have to guard your steel mold against the plastic you are shaping and guard your plastic part against particular metals that will destroy it. These are the different principles that one must master in order to have good design.