Picking the incorrect grade of nylon can seem like an expensive disaster in the making. You fret over part failure, costly mold retooling, and project delay. The plethora of available grades renders the choice seeming daunting. The doubt can freeze a project and cause unnecessary stress, all while performance and cost are at stake. You require an explicit guide to make the proper choice of material confidently.

Nylon 6/6 (PA66) is typically where to start with most injection molding projects. Boasting high mechanical strength, rigidity, good heat stability, and uniform processability, it offers the best overall mix for the broadest variety of demanding applications, as diverse as the auto parts to industrial components. However, the very "best" remains the function of your specific needs of the project.

While PA66 is a fantastic all-around performer, simply defaulting to it without understanding the alternatives can be a missed opportunity. Sometimes, another grade like PA6 might save you money and process time, or a filled nylon might be the only way to meet critical strength requirements. True mastery in design comes from knowing not just what to choose, but why you’re choosing it. Let’s break down the key differences to help you make an informed decision every time.

What’s the Real Difference Between Nylon 6 and Nylon 6/6?

You’re matching the data sheets of the PA6 and the PA66. At first glance, they look almost the same, yet we all know that subtle dissimilarity in the properties of the material can result in dramatic dissimilarity in actual performance. Getting the wrong one can result in a warped part exposed to heat or having insufficient toughness to withstand an impact. The decision seems crucial, and we want to feel that we are making the right choice.

Their most notable variation is in their molecular structure, which also has an impact on their performance. Nylon 6/6 (PA66) has a more regular, tightly packed crystalline structure. This gives it the higher mechanical strengths, being harder, and having a higher heat deflection temperature than Nylon 6 (PA6). The PA6, however, has an irregular structure, which gives it higher impact strengths and, by having a wider processing window, is slightly easier to process.

To really understand when to use one over the other, we need to look beyond the names and into their core characteristics. The names themselves come from the number of carbon atoms in the monomers used to create the polymer chain. PA6 is made from a single monomer with six carbon atoms, while PA66 is made from two different monomers, each containing six carbon atoms. This might seem like a small detail, but it creates the performance differences we see in the final product.

Key Property Comparison

The tighter molecular structure of PA66 makes it more rigid and able to withstand higher temperatures before deforming. PA6, with its less rigid structure, can absorb more impact energy before fracturing. I remember a project for an automotive engine cover. We initially considered PA6 because it was slightly cheaper. However, the high operating temperatures under the hood required the superior heat resistance of PA66. Making that switch in the design phase was a simple decision that prevented a certain field failure.

Here is a table to help you visualize the trade-offs:

| Property | Nylon 6 (PA6) | Nylon 6/6 (PA66) | Why It Matters |

|---|---|---|---|

| Tensile Strength | Good | Excellent (Higher) | PA66 is better for parts under constant tension or load. |

| Stiffness | Good | Excellent (Higher) | PA66 will deform less under load, making it ideal for structural parts. |

| Heat Deflection Temp. | Good (~160°C / 320°F) | Excellent (~200°C / 392°F) | PA66 maintains its integrity at higher temperatures. |

| Impact Strength | Excellent (Higher) | Good | PA6 is tougher and can withstand sudden shocks better. |

| Water Absorption | High | Slightly Lower | Both absorb water, but PA66 is marginally more stable dimensionally. |

| Processing | Easier (Wider Window) | More Demanding (Sharp Melting Point) | PA6 is more forgiving of temperature variations during molding. |

| Cost | Lower | Higher | PA6 can offer cost savings if its properties meet your needs. |

Ultimately, if your part needs to be strong, stiff, and resist heat, PA66 is your go-to. If your part needs to be tough and you want a more forgiving molding process, PA6 is an excellent choice.

Why Choose Nylon Injection Molding Over Other Processing Methods?

The injection molding of nylon is popularly chosen among other processing methods due to the fact that it provides a very good trade-off among efficiency, accuracy, and performance of the material. This is a good process to enable manufacturers to manufacture complex nylon parts with a consistent quality, tight tolerance, and high repeatability, which is suitable for both small as well as large-scale production.

The following are the chief advantages that make nylon injection molding a better option compared to other manufacturing techniques like extrusion, compression molding, or machining.

High Accuracy and Repeatability.

The injection molding offers outstanding dimensions and repeatability. After designing the mold, all the parts manufactured will be of the same shape and size. This degree of accuracy cannot be attained by any other process, such as extrusion or machining, which may necessitate further finishing processes. Nylon injection molding guarantees consistency, which is vital in components that are utilized in automotive, electronics and mechanical.

High-quality Material Properties.

The nature of nylon as a material that is tough, wear-resistant, heat-resistant, and has a chemical resistance makes it a perfect material in injection molding. These properties are uniformly spread throughout the component when injection molded giving the same performance and strength characteristics. Several grades of nylon (reinforced nylon, e.g., glass-filled or carbon-filled) may be injected to achieve increased stiffness, impact strength and dimensional stability.

Multifaceted Form and Architectural Fluidity.

The complex and detailed parts can be produced in one process with nylon injection molding. New capabilities to mold features like threads, undercuts, thin walls and complex geometries eliminate the secondary machining or assembly of the part. This is why it is appropriate to high-performance parts such as gears, bushings, and housings in which parts that require precise designing are necessary.

High Production Efficiency

Large scale production is best achieved through injection molding. When the mold is constructed, thousands of the same parts can be made in a short time with minimum wastage of materials. The cycle times are low and continuous production can be done with automated systems, therefore, making the production cost effective as compared to compression molding or CNC machining.

Superior Surface Finish

Components manufactured using nylon injection molding usually come out with smooth clean surfaces with the mold itself, which do not usually require any post-processing or paint. It is also useful when it comes to consumer goods, interior automotive, and electrical parts in which appearance and consistency is important.

Combines with Advanced Additives and Fillers.

Before injection molding, nylon may be mixed with additives such as glass fiber, carbon fiber, lubricants or flame retardants, with ease. This enables manufacturers to adapt the properties of their products, like strength, wear resistance and heat tolerance, to particular application needs that is not easily done with extrusion and compression molding.

Long-term Production Cost-Effective Tooling.

Although the first mold is not cheap, it is highly cost-effective for producing in bulk. After the mold is created, it will be able to create thousands or even millions of parts through minimum maintenance. This is a long-term payback, which makes nylon injection molding very cost-effective compared to other manufacturing processes in high volume.

The uniqueness of nylon injection molding is that it provides a combination of accuracy, effectiveness, and strength of the product in a single process. It supports elaborate plans, offers high mechanical strength, and also allows mass production at a cost-effective level with minimal wastage. Injection molding has better part quality, reduced cycle times, and extended manufacturing reliability compared to other processes like extrusion, compression molding or machining.

Advantages of Nylon Injection Molding

Nylon injection molding comes with a series of benefits that qualify it as one of the most popular and efficient manufacturing processes of making durable parts of plastics. It is a material that integrates the good qualities of nylon material with the accuracy and efficiency of the injection molding process. The main benefits of nylon injection molding in the industrial and commercial production are outlined below.

Increased strength and toughness.

Nylon has an excellent mechanical strength and toughness. When injection molded, it retains these properties; it attains constant density and structure. The resulting parts are found to be resistant to heavy loads, frequent impacts, and wear over time, hence they are suitable in gears, bearings and structural components.

High Wear and Friction Resistance.

Nylon injection molded components have a high level of resistance to abrasion and friction. This renders them appropriate in the transportation of those components that touch other surfaces, like bushings, pulleys, and mechanical housings. The low coefficient of friction also contributes towards the minimization of energy loss and heat production in the machinery.

Light and High Performance.

Nylon parts are very light compared to metals yet they are strong enough to perform the demanding tasks. This weight saving assists in enhancing the performance of vehicles, machinery and equipment without reducing their performance and reliability.

Very good Thermal Stability.

Even high temperatures do not deteriorate the mechanical properties of nylon. Nylon components that have been injection molded can be exposed to the constant effect of heat without much deformation or loss of properties. This is specifically helpful in engine compartments, electrical housings and industrial machinery.

Design Flexibility

High designing freedom is found in the injection molding process. Complex shapes, fineness of details and incorporated features like threads, clips and hinges can be shaped directly without secondary machining or assembly. This is capable of minimizing the number of parts and makes production easier.

Dimensional Accuracy and Consistency.

Injection molding is offering close tolerances and uniform dimensions of parts. When the design of the mold is completed, all individual parts manufactured will be the same and will fit and work perfectly in assemblies. This fidelity is not easy when using other manufacturing techniques such as machining or extrusion.

Low Service and Durability.

The toughness, wear resistance and chemical stability of nylon results in long service life and low maintenance of parts. This stability enables the manufacturers to save time and cost of replacements in the long run.

Economical Expenses in mass production.

After establishing the mold, nylon injection molding is a very cost effective way of manufacturing high volumes of the same products. The process is also characterized by short cycle times, low material wastes and it is easily automated. This saves labor and makes sure that there is uniform quality in each batch.

Coatability with Reinforcements and Additives.

Nylon may be reinforced with glass fibers, carbon fibers, lubricants or flame retardants so as to better suit a particular application. Correspondingly, glass-filled nylon is used to enhance stiffness, heat resistance, whereas lubricated grades are used to enhance wear performance. These additives are distributed uniformly in the parts, which is done by injection molding.

High Finish and Beauty of the Surface.

Components made of nylon by injection molding can be of smooth, uniform surfaces immediately out of the mold. They might be made in other colors and finishes, and eliminate or minimise the necessity of post-processing. This particularly applies to visible or consumer facing products.

Environmental Benefits

Nylon injection molding produces very little waste of materials since the unused material like sprues and runners can be recycled and re-utilized once more. Bio-based and recyclable grades of nylon also work with the process, which facilitates sustainable manufacturing.

The strength of nylon injection molding combined with thermal stability and flexibility in design is few other manufacturing techniques that can compete with this type of manufacturing. It allows high volume manufacturing of hardwearing, lightweight, and high-performance parts of high quality of surface and dimensional accuracy. These benefits have ensured that it is a choice in various sectors of the automotive industry, electronics, consumer goods and industrial machinery.

When Should You Use Glass-Filled or Carbon-Filled Nylon?

Your raw, empty nylon part simply isn’t tough or rigid enough for the task. You realize that incorporating a filler is the answer, yet you are torn between carbon and glass. The wrong choice can result in incorporating unnecessary cost for performance that’s not needed, or the part can still fall short in the mechanics. You want to know which filler offers the appropriate kick for your particular application.

Resin to Consider: GF Nylon

Use glass-filled (GF) nylon when the requirements are a substantial jump in strength, rigidity, and heat resistance at an affordable cost. It’s the structural component’s workhorse.

Use carbon-filled (CF) nylon when the needs are the absolute maximum in the stiffness-to-weight ratio, the very best in dimensional stability, and electrical conductivity. The result is elite performance, but at a much higher cost.

Think of fillers like rebar in concrete. The nylon base resin provides the form, but the fibers provide the real strength. When you add these short fibers to the nylon, they create an internal scaffold within the plastic. This dramatically improves most mechanical properties, but it’s important to understand the trade-offs between the different types of fillers.

The Workhorse: Glass-Filled (GF) Nylon

Glass fiber is the most common reinforcement used in nylon. It provides a fantastic performance boost for its cost. You’ll typically see it specified in percentages by weight, like 15% GF, 30% GF, or even 50% GF. The more glass you add, the stronger and stiffer the part becomes. However, there’s a trade-off. Higher glass content also makes the material more brittle and significantly more abrasive to the mold steel. For most applications, 30% GF offers a great balance.

We had a client designing a housing for a handheld power drill. The unfilled PA6 prototype felt flimsy and we worried it would crack if dropped. We switched to a 30% glass-filled PA6. The new housing was incredibly rigid and tough, giving the product a high-quality feel and the durability it needed. It’s a perfect example of how GF nylon elevates a part from a simple plastic shell to a robust structural component.

The High-Performer: Carbon-Filled (CF) Nylon

Carbon fiber is the high-end option. Although it is more costly, it has advantages that cannot be equalled by glass. For the same stiffening, a part filled with carbon will weigh less than a similar glass-filled part. This is where weight saving is essential in aerospace, drones, or performance robots. The carbon fibers also possess an extremely low coefficient of thermal expansion (CLTE), so the pieces made out of CF are vastly dimensionally stable over a wide operating temperature range. Another unusual trait that carbon fiber has is that it is possible to make the nylon electrically active, something that is ideal for applications where electrostatic discharge (ESD) protection is required.

Here’s a quick comparison:

| Feature | 30% Glass-Filled (GF) Nylon | 30% Carbon-Filled (CF) Nylon |

|---|---|---|

| Stiffness | Very High | Extremely High |

| Strength | Very High | Very High |

| Weight | Heavier | Lighter |

| Dimensional Stability | Good | Excellent |

| Electrical Property | Insulative | Conductive (can be) |

| Cost | $$ | $$$$ |

The choice is clear: for most structural upgrades, glass-filled nylon is the smart, cost-effective choice. When you need the ultimate in lightweight stiffness or specific electrical properties, carbon-filled nylon is worth the investment.

How Does Moisture Affect Nylon’s Performance in Molding?

You’ve molded a batch of nylon parts that look perfect right out of the machine. But a week later, you get a call that they are failing in the field or no longer fit their assembly. The invisible culprit is likely moisture. Ignoring how nylon absorbs water can lead to drastic dimensional changes and a severe loss of mechanical strength, completely sabotaging an otherwise excellent design.

Nylon is a hygroscopic material, by definition, that absorbs moisture readily in the air. The absorbed water is a plasticizer, reducing the structure’s strength and rigidity, yet making it much tougher and more flexible. Nylon pellets, prior to molding, need to be completely dried to avoid processing defects. In the molded form, there has to be an allowance made for the dimensional and properties shift as the part comes into equilibrium with the environment.

Dealing with moisture in nylon is a two-part challenge: you have to manage it before molding and account for it after molding. Getting either part wrong can ruin your project.

Part 1: Drying is Non-Negotiable Before Molding

If you try to injection mold nylon pellets that have absorbed moisture from the air, the intense heat of the barrel will turn that water into steam. This causes a chemical reaction called hydrolysis, which breaks the polymer chains and permanently degrades the material. The result is a brittle part full of cosmetic defects like silver streaks or splay marks on the surface. To prevent this, you must dry the resin properly. For most nylons, this means using a desiccant dryer for 4 to 6 hours at around 80°C (175°F) to get the moisture content below 0.2%. Never skip this step.

Part 2: Designing for the "Conditioned" State

Once molded, it begins to take up moisture in the air around it until it comes to equilibrium. Meanwhile, its properties alter. I learned the hard way in my early practice. We sent a shipment of tight-limit clips in the "dry as molded" condition. Perfect. The customer was perplexed a week later as the clips would not engage. The reason was that they had taken in moisture in the air and swelled by just enough to be out of spec. Since then, I design all nylon parts using their "conditioned" properties—the conditions they would assume after they come to equilibrium in an average environment (say, 50% Relative Humidity).

Here’s how properties shift from a dry to a conditioned state:

| Property | Dry As Molded | Conditioned (50% RH) | Impact on Design |

|---|---|---|---|

| Tensile Strength | High | Decreases ~30% | Your part will be weaker than it is out of the mold. |

| Stiffness | High | Decreases ~40% | Your part will be much more flexible. |

| Impact Strength | Lower | Increases ~100%+ | Your part will be significantly tougher. |

| Dimensions | Smaller | Swells (Increases) | Your part will grow in size; account for this in fits. |

Always use the material supplier’s "conditioned" data sheet for your design calculations. This ensures your part will perform as expected in its final, real-world environment, not just in the moments after it leaves the mold.

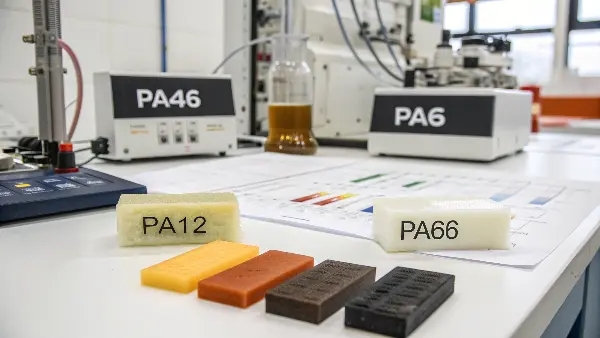

Are There Other Specialty Nylons I Should Consider?

You’re familiar with PA6 and PA66, and how to apply fillers, but how about when presented with an extreme situation in design? An extreme-temperature application, severe chemical exposure, or extreme flexibility can take a standard nylon beyond its capabilities. Utilizing the basics by itself can cost you the ultimate material for the tough task.

Yes. There are solutions in the form of specialty nylons where commodity grades offer no solution. For temperatures above those of PA66, consider using PA46. Where extreme chemical resistance, zero moisture absorption, and exceptional flexibility are needed, choose PA12. These are specialty grades that are the answer to highly specialized engineering needs, but they come at a higher cost and with more stringent processing requirements.

Expanding your material knowledge beyond the common grades can give you a serious design advantage. Let’s look at two powerful specialty nylons that I’ve used to solve tough problems.

The High-Temperature Hero: PA46

When even glass-filled PA66 can’t take the heat, PA46 is the next step up. It has a significantly higher melting point and heat deflection temperature (HDT) than PA66, making it suitable for the most demanding under-the-hood automotive components, high-temperature electrical connectors, and gears that operate in hot, greasy environments. Its highly crystalline structure gives it excellent wear and creep resistance at elevated temperatures. The trade-off is that it absorbs even more water than PA66 and requires very careful processing due to its high melting point, but for pure high-temperature performance, it’s hard to beat.

The Stable & Flexible Choice: PA12

PA12 stands in a league by itself. Its overriding virtue is very low moisture absorption. While PA6 and PA66 will swell and undergo properties with humidity, PA12 stays very stable. It’s the superior option where high-accuracy components such as gears or meter parts are required that can withstand tight tolerances in any environment. It has good chemical resistance as well to an incredibly wide range of chemicals such as fuels and hydraulic fluids, and it’s the first consideration where flexible tubing or fuel lines are required. Although it has no raw strength or rigidity matching PA66, the combination of properties comprised of dimensional stability, chemical resistance, and flexibility can’t be beaten.

Here’s a quick guide to help you place these materials:

| Property | PA66 (Baseline) | PA46 (High-Temp) | PA12 (Stable & Flexible) |

|---|---|---|---|

| Heat Resistance | High | Highest | Moderate |

| Moisture Absorption | High | Very High | Very Low |

| Stiffness | High | Very High | Moderate |

| Flexibility | Low | Low | High |

| Chemical Resistance | Good | Good | Excellent |

| Cost | $$ | $$$$ | $$$ |

Knowing these specialty nylons exist gives you more tools in your toolbox. When a client comes to you with a problem that seems impossible for a standard nylon, you can be the expert who introduces them to the perfect solution.

Conclusion

Nylon selection is more than selecting the strongest material from a data sheet. It’s the understanding of the trade-offs. PA66 has superior all-around strength, and PA6 has toughness and favorable processing. Fillers such as carbon and glass move these plastics into the realm of real structure. And, most importantly, moisture control is the ingredient for success. Controlling these variables is where the good design turns great, where your parts truly function reliably in the real world.