What Are the Key Mold Design Considerations for TPE Materials?

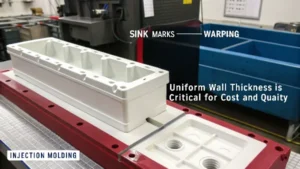

Struggling with defects like flash or sink marks in your TPE parts? These issues often point back to a mold design that doesn’t account for the unique properties of thermoplastic elastomers. This can lead to increased cycle times, high scrap rates, and ultimately, lost profits. Mastering a few key design