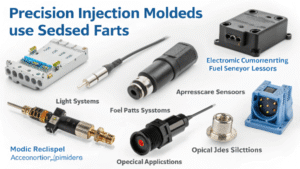

PTFE Manufacturing Methods: Beyond Injection Molding?

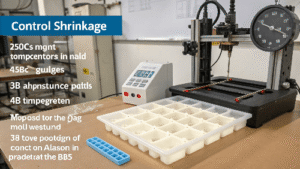

Trying to make parts from PTFE using standard plastic processing? You might find that typical methods like injection molding just don’t work for this unique material. This can be frustrating and costly if you’re expecting PTFE to behave like other thermoplastics. PTFE (Polytetrafluoroethylene)1 cannot be effectively processed using conventional melt