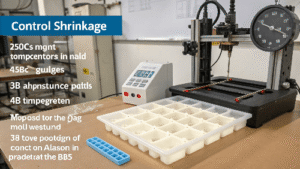

How Can You Prevent Ugly Weld Lines in Your Plastic Parts?

You’ve just received a batch of new plastic parts, but they’re marred by faint, unsightly lines where the plastic flowed together. These weld lines not only ruin the cosmetic appearance but can also create weak spots, leading to part failure and customer complaints. But what if you could anticipate and