Designing of complex parts that need both metal strength and versatility of plastics can prove to be a mess actually. The conventional operations of assembling tend to be very expensive, time-consuming as well as unreliable. Probably, you need a more built-in and resistant service.

Insert Molding is something that CKMOLD is able to offer as the ability to combine metal (such as threaded inserts, pins, contacts etc.) with other thermoplastics in one sweeping automated sweep. This produces sturdy, long lived and intricate components, minimising assembly time, and enhancing overall products quality in high tech applications, such as electronics and automobile components.

I have worked over a decades-long span of years in the mold industry, starting off working in a mold factory and then setting up my own mold and CNC trading company. I saw the effect of a wrong manufacturing partner and process which can break a project with my own eyes. Our mission at CKMOLD is to be a master of the right molding and a significant role in that is to share knowledge with our targets and others. So let us see how our expertise in insert molding and specifically in metal plastic combinations could help your complex designs.

What Exactly Are CKMOLD’s Insert Molding Capabilities?

You are aware that insert molding is there yet what are the particular advantages of a provider when it comes to offering quality outputs of challenging applications? It is so irritating when there is no way to find a supplier who will be able to look deep and grasp the complexity of the matter how to combine various materials successfully and particularly metal and plastic.

Insert molding functions of CKMOLD consist of accurate positioning of the insert (during manual or automated insertion), excellent experience with regard to the selection of materials to ensure a robust bond between the metal and plastic, this is compounded by compound mold-design skills to enable good retention of the insert, and stringent production1 controls. This provides consistent high strength amalgamated sections with numerous insert types and thermo plastic resins.

Dive deeper Paragraph:

At CKMOLD, when we talk about our insert molding capabilities, we’re focusing on several key areas that are critical for successfully combining metal with plastic.

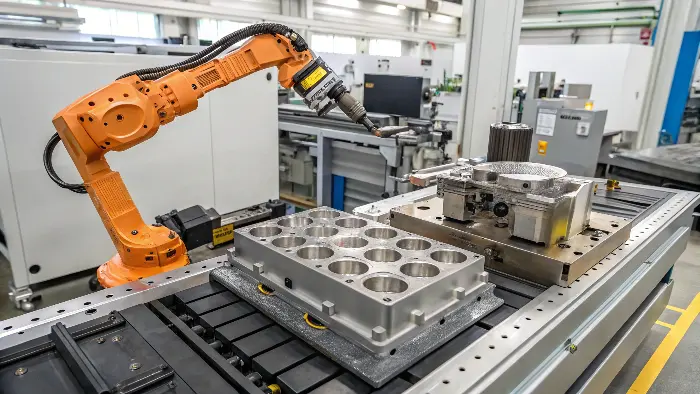

First is precision in insert placement. Whether we use robotic automation for high-volume runs or skilled manual placement for more intricate, lower-volume projects, the accuracy of where that metal insert sits in the mold is paramount. Even a slight misalignment can lead to a faulty part or damage to the expensive mold. We work to tight tolerances to ensure every insert is perfectly positioned.

Second is our concept of materials and bonding. Plastics do not all stick well on all metals. Our experience includes all sorts of metals such as brass, stainless steel, aluminum and all grades of steel, and an extensive line of thermoplastics: ABS, polycarbonate (PC), nylon (PA), PEEK and polypropylene (PP). We take into account such factors as a difference in thermal expansion, preparation of the surface of the metal insert and the way of creating the mechanical interlock (knurl, grooves, etc. on the insert itself), in order to make the bond as strong as possible.

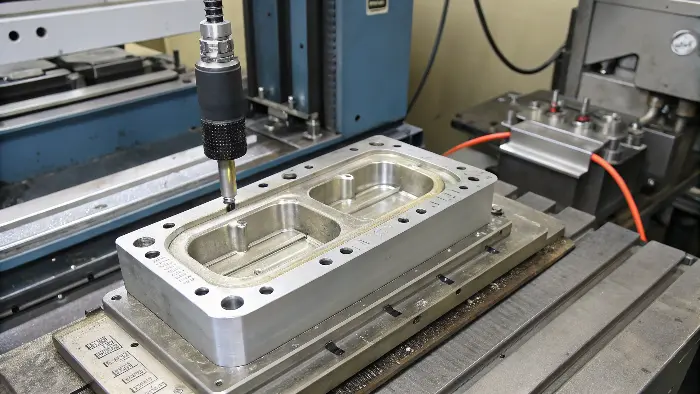

Third, we have essential expertise in mold design. The mold is not merely a hole, but a complicated machine, which has to firmly fix the metal insert against the high odds of the plastic melt injection. It requires such features that will avoid shifting of the insert, that plastic does not flash onto portions of the insert where it is not desirable and that the plastic properly flows around the insert so that the insert is fully encapsulated. I recall a project where the connector pins were extremely delicate, the shape of the mold to keep these connector pins safe during the shot was complex to the extreme.

Finally, process control ties it all together. We meticulously control injection speed, pressure, melt temperature, and cooling times to optimize the molding conditions for each specific metal-plastic combination. This consistent control is what allows us to produce reliable, high-quality parts batch after batch.

Insert molding Technologies and Machinery

As insert molding is a very tedious and accurate procedure, it demands special equipment and technologies. Examples of the same are:

- Insert molding requires a severe tightening up on injection parameters like pressure, temperature and the speed at which it is injected. Advanced control systems are inbuilt in specialized injection molding machines to enable adjustment and monitoring of such parameters with precision. This control is important so that binding is uniform and defects reduced and a strong bonding between the two is achieved by the plastic and the insert.

- The insert molding machines are frequently used with robotic systems that add inserts into molds through high precision and consistency. Automated positioning inserts using robotic arms and other automated devices will guarantee accurate and consistent insert positions with shortened cycle times and repeatability which is ideal in large quantities This kind of automation is essential with regard to high production efficiency and affordability of labor.

- As discussed above, there is a need of a very precise mold to fit both the plastic and the insert materials. The objective of these molds is to create tight tolerance and complex geometries because these molds need to hold the insert steadily and the molten plastic must be able to fill the stem and cover the insert optically. The high-performance molds may incorporate multi-cavity tooling, fine alignment machineries, and intricate gating systems to control the flow to the plastic around the insert. Special purpose hot runner systems holding the plastic in a molten condition in the mold causes less wastage and shortens the cycle times.

- As mentioned earlier, proper cooling should be undertaken to harden the plastic around insert. Specialized cooling equipment will frequently involve sophisticated cooling systems capable of being adjusted to the needs of the insert and the plastic materials to achieve optimum cooling rates and avoid defects including warping.

- There must also be improved ejection system to push the completed product away without affecting insert and adjacent plastic. Specialized equipment includes carefully designed ejection mechanisms that can handle delicate and complex parts, ensuring smooth and damage-free ejection.

When combined, these unique characteristics guarantee the creation of dependable, high-quality parts with the required mechanical characteristics and functionality.

Can You Give a Real-World Example of Insert Molding from CKMOLD?

It is one thing to read abstract definitions, and then it is a different story when one sees a real life application in which the benefits become more apparent. The question on how this process actually translates to real product improvement may be what is on your mind, especially when it comes to blending metal and plastic.

A great example of insert molding is creating an automotive sensor housing where brass connector pins are precisely molded into a robust PBT (polybutylene terephthalate) plastic body. This ensures a sealed, durable connection point, vital for electronics exposed to engine heat and vibrations, a common project type we handle at CKMOLD.

Dive deeper Paragraph:

I would like to talk more about that automotive sensor housing because it truly demonstrates the potential of insert continuous injection of metal and plastic. The client required a component that would survive an extreme under-hood environment, which was characterized by flucuation of temperature, moisture, and vibrations without being affected by the same, and an ideal connectivity in electrical terms.

The Problem Solved: They were using a combination of ditches and were manually putting the connector pins into the housing which was designed in two or three parts. This was cumbersome to do and the seals were a point of failure and water ingress causing sensors to fail. The insert molding technique enabled us to make one big piece out of it which significantly increased the hermetic seal and sturdiness of the product.

- Insert Material: We used specific brass alloy pins chosen for their conductivity and corrosion resistance.

- Plastic Material: Glass-filled PBT was selected for its high-temperature resistance, dimensional stability, and good adhesion to the brass pins after proper surface treatment of the pins.

- Difficulties We Overcame: The primary difficulties were making sure the delicate pins stayed precisely positioned and perfectly straight throughout the molten PBT injection process. We also had to prevent the PBT from flowing onto the critical contact surfaces of the pins. This required very precise mold design and careful control of the injection parameters.

- Benefits Achieved: The final insert-molded part had fewer components, significantly reduced assembly time for the client, offered superior environmental sealing, and increased the overall reliability of their sensor.

I recall when I was building my trading company, a client in the consumer electronics space had an issue with screws constantly stripping the plastic threads in their device enclosures during assembly and by end-users. We helped them redesign the enclosure to incorporate brass threaded inserts using insert molding. This small change dramatically improved the product’s durability and user experience, and it helped their business grow. That’s the kind of practical problem-solving that makes this work so rewarding.

What’s the Molding Process for Thermoplastics in Insert Molding at CKMOLD?

Understanding the "how" behind insert molding, especially with thermoplastics and metal inserts, can help you design better parts for the process. If the process seems like a black box, it’s hard to optimize your designs for manufacturability and cost-effectiveness.

The molding process for thermoplastics in insert molding at CKMOLD involves: 1. Precise placement of the metal insert into the mold cavity. 2. Securely clamping the mold shut. 3. Injecting molten thermoplastic resin around the insert. 4. Applying holding pressure as it cools. 5. Allowing adequate cooling for solidification. 6. Ejecting the finished, integrated component.

Dive deeper Paragraph:

Let’s walk through the typical steps when we’re insert molding a metal component with a thermoplastic material at CKMOLD. This process is a specialized form of injection molding.

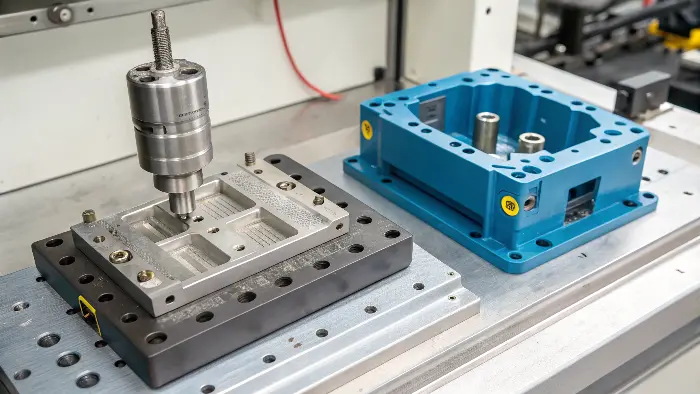

- Insert Preparation and Loading: This first step is critical. The metal inserts (e.g., threaded bushings, pins, plates) are inspected. Sometimes they require pre-treatment like cleaning or even pre-heating. Pre-heating can improve the bond with the plastic and reduce stress in the final part. Then, the insert is carefully placed into its designated position within the mold cavity. This can be done manually by an operator for complex or low-volume parts, or by a robotic arm for high-speed, high-volume production. Accuracy here is key.

- Mold Closure and Clamping: Once the insert is securely in place, the injection molding machine closes the two halves of the mold. A high clamping force is applied to keep the mold tightly shut against the pressure of the injected plastic.

- Injection: The thermoplastic material, which has been melted to a precise temperature in the machine’s barrel, is then injected under high pressure into the closed mold. The molten plastic flows into the cavity and around the metal insert. We carefully control the injection speed and pressure to ensure the plastic fills the cavity completely without dislodging or damaging the insert.

- Packing and Holding: After the cavity is filled, we maintain pressure (the packing or holding phase) for a set time. This forces more material into the mold to compensate for shrinkage as the plastic begins to cool and solidify. This is vital for part accuracy and minimizing voids.

- Cooling: The mold is kept closed while the plastic cools and solidifies around the insert, forming a strong mechanical (and sometimes chemical) bond. The cooling time depends on the type of thermoplastic, the wall thickness of the part, and the mold temperature.

- Mold Opening and Ejection: Once the part has cooled sufficiently, the mold opens. Ejector pins then push the finished part, with the metal insert now an integral component, out of the mold.

Throughout this cycle, parameters like melt temperature, mold temperature, injection pressure, holding pressure, and cooling time are precisely controlled by the molding machine, based on our established process settings for that specific part and material combination. This ensures consistency and quality.

How Does Insert Molding Differ From Overmolding at CKMOLD?

Insert molding and overmolding have gotten to be interchanged indifferently phrases which can prompt a misunderstanding and loss of communication when initially having a project talk. Misconstruing the process and selecting the wrong process may be an expensive and time-consuming process to your project.

Insert molding Insert molding at CKMOLD is the act of inserting a distinct, usually metal, part into a mold prior to start of a plastic injection cycle. Overmolding though has something to with molding a plastic material onto an already existing part (which might be plastic or metal) and which is normally referred to as a substrate. Although both are used to produce multi-material parts, the process is different in flow, intentions and usual applications..

Dive deeper Paragraph:

It’s a common point of clarification I make with clients. Both techniques are fantastic for creating parts with multiple materials, but they are distinct.

Here’s a table to highlight the differences from CKMOLD’s operational perspective:

| Feature | Insert Molding (CKMOLD’s Approach) | Overmolding (CKMOLD’s Approach) |

|---|---|---|

| Primary Goal | To embed a functional or structural component (often metal) within a plastic part. | To add an outer layer (e.g., soft grip, seal, aesthetic feature) onto an existing substrate part. |

| The "Insert" | A pre-formed, distinct component (e.g., metal bushing, ceramic pin, another plastic part) placed into the mold. | The "substrate" is the first part, which is then placed in another mold (or different cavity of same mold) for the second material. |

| Process Sequence | Insert is placed before a single injection molding cycle that encapsulates it. | Substrate is typically molded first (or supplied). Then, a second material is molded over it in a subsequent step or shot. |

| Typical Use Cases | Creating strong metal threads in plastic, encapsulating electronic components, integrating structural supports. | Adding soft-touch TPE grips to rigid handles, creating watertight seals, multi-color aesthetic effects. |

| CKMOLD Focus | Precision placement of diverse inserts, achieving robust mechanical bonds between dissimilar materials (especially metal-plastic). | Material compatibility for strong adhesion between the substrate and overmold layer, complex two-shot (2K) molding capabilities. |

I’ve guided many clients through this decision. For example, if you need a robust metal screw thread inside a plastic knob, that’s a clear case for insert molding. We place the metal threaded insert into the mold, and then the plastic knob is molded around it. But if you want to add a soft, rubbery grip onto an already existing rigid plastic handle, that’s overmolding. The handle is the substrate, and we mold the softer material onto its surface. Sometimes, a very complex part might even use both techniques in different areas! Our job at CKMOLD is to understand your application and recommend the most efficient and effective process.

Conclusion

CKMOLD’s insert molding capabilities, particularly for combining metal and plastic, offer a powerful way to create advanced, integrated components. By understanding our specific strengths in precision, material science, mold design, and process control, along with real-world applications and the nuances of the thermoplastic molding process, you can better leverage this technology for stronger, more reliable, and often more cost-effective products. We’re dedicated to helping you "Master Molding Right."