Tired of your injection molding process wasting resources and extra plastic? It’s a big problem that’s bad for the environment and your bottom line. But what if smart design decisions could reduce that waste and make your operations more sustainable?

To reduce waste, injection molds can be designed with optimized runner systems like hot runners that store molten plastic and minimize scrap. Proper gate design and location also reduces material loss. Molding the mold with long life materials also extends the life of the mold and reduces mold replacement waste. And designing for material flow and part ejection eliminates defects that result in scrap parts.

We all know waste in manufacturing is a big deal. I’ve seen firsthand how small inefficiencies add up to big losses. The good news is we can address this directly by focusing on the injection mold design phase. Let’s look at how detailed design can lead to a more tolerant and cost effective manufacturing process. This journey will show us what to do to make a real difference.

Does injection molding create waste?

It’s sad to see plastic waste mountains isn’t it? You wonder if injection molding, as efficient as it is, must create a ton of waste. The reality is, if you don’t plan ahead, yes it does, and it hurts your bottom line and the environment too.

Yes, injection molding can create waste in one way or another. Sources are sprues and runners on cold runner systems, defective parts due to design or process irregularities, material degradation due to mishandling, and overproduction. But much of the waste can be eliminated or minimized in bulk through good design and process engineering.

The amount of material that didn’t make it into the finished product shocked me when I first started working in the mold industry. Rejected pieces, runners, and spruces were all too prevalent. This waste includes lost energy, time, and resources in addition to discarded plastic. The first step in determining how to eliminate this waste is to understand its source. Let’s dissect the typical offenders.

Sources of Waste in Injection Molding

| Waste Source | Description | Impact |

|---|---|---|

| Sprues & Runners | In cold runner systems, these channels deliver molten plastic to the mold cavities but solidify with the part. | Material scrap, requires regrinding or disposal. |

| Defective Parts | Parts that don’t meet quality standards due to warpage, sink marks, short shots, flash, etc. | Material loss, wasted machine time, energy. |

| Material Purging | Cleaning out the barrel of the injection molding machine between material changes or colors. | Significant material scrap. |

| Overproduction | Producing more parts than needed due to poor forecasting or minimum batch sizes. | Unused inventory, potential obsolescence. |

| Mold Wear/Damage | An old or damaged mold can produce faulty parts, leading to increased scrap. | Increased defects, material waste. |

| Setup Scrap | Parts produced during the initial setup and calibration of the molding machine and mold. | Necessary but can be minimized. |

The total waste load of an injection molding process is influenced by each of these sources. Cold runners, for example, at times can account for a very high proportion of total shot weight, especially with small parts or multi-cavity tools. Scrap parts waste not only material, but also the energy and time used to produce them. I remember a job where a badly designed gate resulted in a high percentage of defects, and the scrap was appalling until we redesigned that small piece. It taught me the importance of every design detail.

How are injection molds designed?

Have you ever been curious about what goes into the heart of plastic production – the injection mold itself? It seems overwhelming, and it is, but learning a few things about the basics can give us a sense of where waste reduction changes can be made. It’s an engineering technology that involves some good old-fashioned manufacturing common sense.

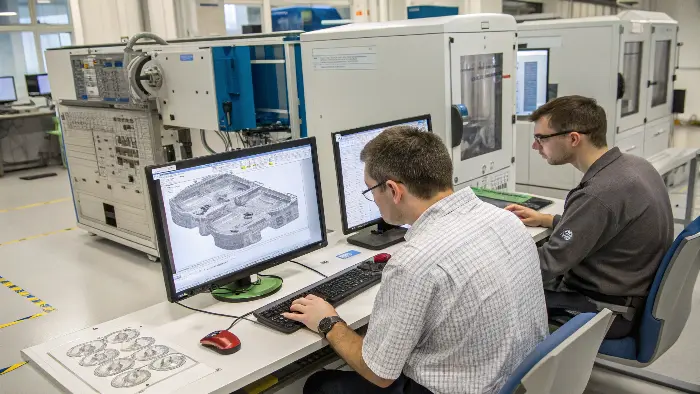

CAD software is employed to design injection molds, starting from the 3D model of the part to be produced. The core and the cavity are subsequently designed by designers, which shape the part. Designers also establish the runner system to guide plastic, the gating system for plastic flow into the cavity, cooling channels to solidify plastic, and an ejection system to eject the produced part. Material choice for the part and mold is also crucial.

An injection mold’s design is an intricate procedure. Making a cavity that fits the part shape is not enough. In-depth knowledge of thermal dynamics, plastic flow behavior, and material properties are required. Over the years, I’ve discovered that a well-designed mold is a collaborative effort between engineering and art. It is the cornerstone of effectively producing high-quality parts. Let us examine in more detail the essential components of this design process.

Key Elements in Mold Design

A standard injection mold design process incorporates a number of important steps and considerations:

-

Part Design Analysis:

- We start by looking at the 3D part model of the product designer. We look for features that will cause molding problems, like undercuts, sharp corners, or thick sections.

- Draft angles are required. These are slight tapers on the surface of the components that enable you to take it out of the mold easily. Without draft, parts can be stuck, warped, or cause mold wear.

-

Cavity and Mold Core Design:

- These two halves in the mold are joined to form the shape of the part. The outside surfaces are formed by the cavity and the inside surfaces by the core.

- Accuracy is the priority here. The measurements need to be precise in terms of material shrinkage.

-

Runner and Gating System:

- The runner system is a channel system that transports molten plastic from the nozzle of the injection molding machine to the mold cavities.

- The gate is the location where the plastic itself enters the cavity. Gate type, size, and location are critical to determining part quality and minimizing waste. More on this later.

-

Cooling System Design:

- Channels are created in the mold halves to make a flow of a cooling liquid (typically water).

- Proper cooling is important in reducing the cycle time and ensuring consistent part quality. Non-uniform cooling can lead to warpage and other forms of defects.

-

Ejection System Design:

- This mechanism pushes the hardened part out of the mold after it is chilled. It typically comprises ejector pins, sleeves, or stripper plates. * The construction should enable the part to be ejected safely.

- Mold Material Selection: * Molds can be built from various steels (i.e., P20, H13, S7) or aluminum, based on the number of parts being made, part material, and desired mold life. The choice of material affects durability and indirectly waste from mold failure.

I remember a customer who was having trouble with high defect rates. Upon analyzing their mold design, we discovered that the cooling channels were positioned inefficiently, resulting in uneven cooling and distorted components. Their output was significantly increased and waste was decreased by a cooling system overhaul. This demonstrates the interdependence of all these design components.

How Does Mold Design Impact Material Waste?

Mold design directly affects material wastage in injection molding through material flow, part quality, and manufacturing efficiency. Non-uniform part designs with non-uniform wall thickness result in overpacking or defects, material wastage, whereas uniform designs use material to the optimum. Inefficient cold runners or poorly located gates result in runner and sprue waste, whereas hot runners or well-located gates minimize scrap. Single-cavity molds generate more wastes per part than multi-cavity molds, dispensing material in an efficient way.

Inefficient precision design generates flash, whereas inefficient cooling systems generate defects or material degradation, resulting in scrap. Designs with material recyclability and mold flow simulations, however, reduce scrap by maximizing flow and eliminating trial-and-error. Optimum mold design uses maximum minimum material, minimizes defects, and encourages sustainability, whereas poor design maximizes waste and cost.

How to reduce waste in injection molding?

Faced with plastic waste, are you looking for viable solutions to lean and green your injection molding operation? It’s a wish we can all make, and the best news is that there are viable strategies, and more significantly, in mold design, that can actually make a difference. The key is to be smart in the first place.

To reduce waste, take note of material optimization by using recycled or bio-based materials and hot runner systems. Streamline molds for efficiency by using optimized gating and runner systems, lean manufacturing techniques, and designing for extended mold life. These directly reduce material scrap and improve overall resource effectiveness.

Reducing garbage isn’t just about being ecologically aware; it’s also about improving efficiency and saving costs. I’ve witnessed businesses change their operations by implementing more intelligent material and design choices. It often begins with an affirmation to look at every stage of the process with a critical eye. Let’s dive into some detailed design-centered techniques.

Material Optimization Strategies

One of the simplest ways of reducing waste is to be more selective about the materials we use.

-

Use of Recycled and Recyclable Materials:

-

Incorporating post-consumer or post-industrial plastic regrind into your product can significantly reduce virgin plastic usage. Ensuring that the quality of the regrind is at an acceptable level for the usage is important.

-

Parts manufacturing and material selection that can easily be recycled at the end of their life also contributes to a circular economy.

-

I worked with a firm that had an effective system for collecting and recycling their in-plant scrap. They closely monitored the level of regrind that was blended with virgin material so that part quality remained high while significantly reducing their raw material expenses and scrap.

-

Hot Runner Systems:

-

Hi, as opposed to cold runner systems in which the runners and sprue freeze with the part and are scrap (or must be reground), hot runner systems keep the plastic in the runners in a molten form. The plastic is now ready to be used in the next shot.

-

Advantages:

-

Eliminates runner scrap, saving much material, especially for extended runs or large parts.

-

Reduces cycle times as there is no runner to cool.

-

Regularly improves part quality and consistency. * While hot runner molds cost more to buy, reducing material cost and the increased efficiency can repay the investment within a short period of time.

Mold Efficiency Design

Optimizing the design of the mold itself is key.

-

Improved Gating and Runner Systems (for Cold Runners also):

-

Even when a cold runner is utilized, its design can be optimized. The goal is to design the runners as short and as small in diameter as possible without sacrificing full and balanced filling of all cavities.

-

Optimal gate design (size, type, location) is essential. It dictates how plastic enters the cavity, impacts part quality (e.g., avoiding jetting or sink marks), and dictates ease of gate removal from part with less scarring or waste.

-

Multi-cavity molds require balanced runner systems in order to enable all cavities to fill at the same pressure and rate. This prevents overpacking some cavities and underfilling others, reducing part-to-part variation and scrap.

-

Extending Mold Life:

-

Proper heat treatment and high-quality, long-lasting material lengthen their service life.

-

Regular cleaning, servicing, and proper storage are also required.

-

A longer-lasting mold results in fewer replacements, which reduces waste in making new molds and disposing of the old. Always I recommend clients to invest a little more for a good mold initially to avoid a lot of hassle and money in the long run. These are basic design principles. By thinking about how material is being utilized and how the mold operates, we can accomplish a great deal to reduce waste.

Key Tips for Reducing Material Waste when injection moulds are designed

Tips to Reduce Material Waste in Injection Mold Design

Reducing material waste in injection mold design is key to efficiency and cost savings in injection molding.

1. Optimize Part Shape:

Design parts with uniform wall thickness to get consistent material flow and minimize excess. Avoid thick sections that cause overpacking or sink marks.

Simplify geometries to reduce material volume without losing strength.

2. Use Efficient Runners:

Use hot runners to eliminate cold runner waste, they keep the material molten and reusable.

For cold runners, design thin, short runners to minimize sprue and runner material.

3. Multi-Cavity Molds:

Use multi-cavity molds to make multiple parts per cycle, reduce material waste in runners and sprues per part.

Balance cavity layouts to get even material distribution.

4. Use Simulation Software:

Use mold flow analysis to simulate material flow, find overfill areas and optimize gate placement, reduce trial-and-error waste.

Predict and adjust for shrinkage to avoid material waste.

5. Choose the Right Gate:

Choose gate types (e.g. edge or pinpoint gates) that minimize material use while getting proper filling.

Place gates to reduce runner length and waste.

These are some key tips for reducing material waste when injection moulds are designed

How to make injection molding more sustainable?

Do you want to further reduce waste and increase the sustainability of your injection molding business as a whole? The adverse environmental effects can be considerably reduced by broader techniques that go beyond mold design. The goal is to establish a manufacturing ecosystem that is more responsible and circular.

Make injection molding more environmentally friendly by adding closed-loop recycling systems to recycle internal plastic waste. Employ energy-efficient machinery and processes, reduce water usage for cooling, and utilize bio-based or biodegradable plastics where feasible. Moreover, disassembly and recycling part design contributes to a circular economy.

In manufacturing, sustainability is a process rather than a final goal. I’ve seen the economy evolve, and there’s a growing understanding that tolerable procedures are not just good for the planet but also good for companies. It involves looking at the bigger picture, from plain content sourcing to end-of-life goods control. Let’s investigate some key sustainable practices.

Implementing Sustainable Practices

While mold design is a critical starting point for waste reduction, other operational and strategic choices enhance sustainability:

-

Closed-Loop Recycling:

- This involves setting up systems within your facility to collect, regrind, and reintroduce plastic scrap (like runners from cold runner systems, or rejected parts) back into the production process.

- This creates a "closed loop" where waste material is immediately repurposed, reducing the need for virgin plastic and minimizing disposal.

- It requires good quality control to ensure the regrind doesn’t compromise the final product’s integrity. I helped a client implement a simple color-coded bin system for different types of scrap, making it easier to manage their regrind process effectively.

-

Energy Efficiency:

- Modern injection molding machines are often more energy-efficient than older models. Consider upgrading to all-electric or hybrid machines.

- Optimize process parameters (like melt temperature, injection speed, and cooling time) to use only the necessary amount of energy.

- Regular maintenance of machinery ensures it operates at peak efficiency.

-

Water Conservation:

- Mold cooling is a significant water consumer. Implementing closed-loop cooling tower systems can recycle and reuse water, drastically reducing consumption compared to open-loop systems.

- Regularly check for leaks in cooling lines and optimize flow rates.

-

Lean Manufacturing Principles:

- Applying lean principles helps identify and eliminate all forms of waste in the production process – not just material scrap, but also wasted time, motion, energy, and overproduction.

- Practices like 5S (Sort, Set in order, Shine, Standardize, Sustain), value stream mapping, and continuous improvement (Kaizen) can streamline operations and reduce overall resource consumption.

-

Designing for Disassembly and Recyclability (DfD/DfR):

- While this is more on the product design side, mold designers can contribute by ensuring parts are molded in ways that facilitate easy separation of different materials at the end of the product’s life.

- Using single material types where possible, or clearly marking different plastics, aids recycling efforts.

By adopting these broader sustainable practices in conjunction with waste-minimizing mold designs, we can significantly improve the environmental footprint of injection molding. It’s about a holistic approach to responsible manufacturing.

Conclusion

Waste reduction in injection molding starts with smart design. Optimizing runner systems, hot runners, good selection of mold material, and efficient material flow in design allows us to significantly cut scrap. Such design choices, along with eco-friendly measures like closed-loop recycling and energy efficiency, pave the way for a greener, less expensive future for manufacturing. It’s a matter of extracting every gram of plastic.