Are you struggling with TPE over-molded parts that peel, separate, or fail under stress? This common problem can lead to product recalls, wasted materials, and a loss of customer trust. You might be wondering if achieving that seamless, permanent bond is even possible. The key is understanding that a successful bond isn’t magic; it’s a science that combines material chemistry, smart design, and precise process control to create an inseparable connection.

To master TPE over-molding, you must focus on three core principles. First, ensure chemical compatibility by selecting a TPE grade and a rigid substrate that can form a strong molecular bond when melted together. Second, design the rigid part with mechanical interlocks like undercuts, shut-off grooves, or through-holes that physically anchor the TPE. Finally, you must optimize your injection molding process parameters, especially melt temperature and injection speed, to promote a complete and permanent fusion between the two materials.

Getting that flawless bond is the ultimate goal in any over-molding project. It’s what separates a premium product from a cheap imitation. This bond doesn’t just happen by chance; it’s the result of two types of adhesion working together: chemical bonding and mechanical interlocking. A chemical bond is a molecular-level fusion between the two materials, while a mechanical bond is a physical connection, like a key in a lock. To achieve true mastery, you need both. Let’s break down how to get them right, starting with the foundation of any great bond: material selection.

Why Is Material Selection The First Step To a Perfect TPE Bond?

Have you ever picked a high-quality TPE and a durable substrate, only to find they refuse to stick together? It’s a frustrating experience that can make you question your entire process and material choices. You start to think your project is impossible. The reality is that material compatibility isn’t about quality alone; it’s about chemistry. Understanding which materials work together is the first and most critical step toward creating a bond that will never fail.

Material selection is crucial because the strength of a TPE over-mold bond primarily relies on chemical compatibility. For a powerful molecular bond to form, the TPE and the rigid substrate must have similar chemical structures and polarity. For instance, styrenic-based TPEs (TPE-S) bond exceptionally well to non-polar plastics like polypropylene (PP). In contrast, polar materials like ABS or PC require polar TPEs, such as thermoplastic polyurethane (TPU) or copolyester (COPE), to achieve strong adhesion. Choosing incompatible materials guarantees a weak bond, no matter how perfect your design or process is.

The success of your over-molding project is often decided before the mold even closes. It’s decided when you choose your materials. Think of it like trying to mix oil and water—if the fundamental chemistries are incompatible, they will never truly combine. The same principle applies to plastics.

Understanding Chemical Polarity

At the molecular level, plastics are either "polar" or "non-polar."

- Polar plastics like ABS, Polycarbonate (PC), and Nylon have an uneven distribution of electron charges in their molecules.

- Non-polar plastics like Polypropylene (PP) and Polyethylene (PE) have an even charge distribution.

For a strong chemical bond, you must match polar TPEs with polar substrates and non-polar TPEs with non-polar substrates. This "like-attracts-like" rule is non-negotiable. Trying to bond a non-polar TPE-S to a polar PC substrate without a special adhesion promoter is a recipe for failure.

TPE and Substrate Compatibility Chart

To make this easier, here is a quick reference table. I’ve used this countless times to guide clients in making the right choice from the start.

| TPE Type | Common Name | Compatible Substrates | Bond Quality |

|---|---|---|---|

| TPE-S (SEBS/SBS) | Styrenic | PP, PE, PS, TPO | Excellent |

| TPU | Polyurethane | ABS, PC, PC/ABS, PMMA | Excellent |

| TPV | Vulcanizate | PP, EPDM | Excellent |

| COPE (TPE-E) | Copolyester | PC, PBT, PETG, ABS | Excellent |

| COPA (TPE-A) | Copolyamide | PA6, PA66 (Nylon) | Excellent |

Remember, this is a starting point. Always consult the material supplier’s datasheet. They provide specific bonding information for their grades, and some companies have developed special TPE formulations that can bridge the compatibility gap and bond to substrates they normally wouldn’t.

How Can Part Design Create An Unbreakable Mechanical Lock?

You’ve selected chemically compatible materials, yet you’re still not getting the robust bond your product requires for long-term durability. The chemical bond is good, but it might not be enough to withstand the prying, twisting, or pulling forces of real-world use. It’s disheartening when a part that looks perfect fails under physical stress. This is where clever part design transforms a good bond into an unbreakable one by adding a physical, mechanical connection.

To create an unbreakable mechanical lock, your part design must incorporate features that physically restrain the TPE, preventing it from peeling or separating from the hard substrate. This is achieved through strategic design elements like undercuts, shut-off grooves, or through-holes. These features allow the molten TPE to flow into and solidify within the substrate, forming a solid mechanical interlock. This physical connection works in tandem with the chemical bond to create a bond that can withstand significant force, ensuring product integrity and longevity.

While a chemical bond is essential, you should never rely on it alone, especially for products that will be frequently handled, stretched, or bent. A mechanical bond is your insurance policy. I once worked on a project for a power tool handle. The chemical bond between the TPE grip and the PC housing was decent, but during drop tests, the edges of the grip would start peeling. We went back to the design phase and added a simple groove around the entire perimeter of the TPE area. This small change created a mechanical hook that locked the TPE edge in place, and the peeling problem was completely solved.

Key Mechanical Interlocking Features

Let’s look at some of the most effective design features you can use to create a strong mechanical bond.

-

Undercuts and Grooves: These are small channels or lips designed into the substrate. As the TPE is injected, it flows into these features and, once cooled, acts like a hook or anchor. A groove around the perimeter of the over-mold is one of the most effective ways to prevent edge peeling.

-

Through-Holes: By designing holes that pass completely through the substrate in the over-mold area, you allow the TPE to flow through and connect on both sides. This creates a TPE "rivet" that physically clamps the soft material to the hard plastic from two directions.

-

Textured Surfaces: Applying a rough or textured finish (like an MT-11020 from the Mold-Tech Graining catalogue) to the substrate’s bonding surface significantly increases the surface area. This gives the TPE more to grip onto, enhancing both the chemical and mechanical bond.

Design Guidelines for Mechanical Interlocks

| Feature | Design Recommendation | Why It Works |

|---|---|---|

| Shut-off Groove | Minimum depth and width of 1mm. Place around the over-mold perimeter. | Prevents the TPE from peeling up at the edges, which is the most common failure point. |

| Through-Holes | Diameter should be at least 1.5 times the TPE wall thickness. | Creates a strong TPE rivet, locking the material from both sides of the substrate. |

| TPE Thickness | Maintain a minimum thickness of 1.5mm to 2mm. | Ensures there is enough material mass to create a durable-feeling part and fill features. |

| Sharp Corners | Avoid sharp internal corners on the substrate; use generous radii instead. | Prevents stress concentration points and helps the TPE material flow smoothly. |

By incorporating these features, you are no longer just gluing two surfaces together; you are physically weaving them into one another. This dual-pronged approach of chemical and mechanical bonding is the secret to creating TPE over-molded parts that last.

What Are The Critical Mold Design Features For Flawless Over-molding?

Your materials are compatible and your part design includes strong mechanical locks. However, during production, you’re experiencing issues like flash, incomplete filling, or damage to the substrate inserts. Your operators struggle with inconsistent quality, slowing down production and increasing scrap rates. These problems often point not to the part, but to the tool itself. An improperly designed mold can undermine even the best material and part design choices, making flawless execution impossible.

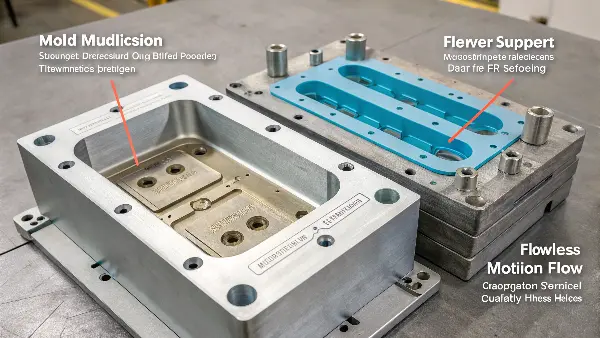

A successful over-molding mold must be designed for precision, stability, and efficient TPE flow. Critical features include robust insert support to prevent the substrate from shifting or deforming under high injection pressure. The gating strategy is also key; gates should be placed to direct TPE flow across the bonding surface without causing substrate erosion. Finally, effective venting is essential to allow trapped air to escape, preventing short shots and ensuring the TPE cavity fills completely for a perfect, void-free bond.

The mold is where theory becomes reality. I’ve seen beautifully engineered parts fail spectacularly because of a poorly thought-out mold. The most common mistake is underestimating the forces involved. When you inject molten TPE at high pressure, it will find any weakness. If the substrate insert isn’t held perfectly rigid, it will move. If air can’t escape, the TPE can’t fill the space. A great over-molding tool anticipates these challenges and is built to overcome them. For high-volume production, we often recommend a two-shot rotary platen mold, which molds the substrate and then rotates it into the second cavity for over-molding in one seamless cycle. This keeps the substrate hot, promoting an excellent chemical bond.

Core Principles of Over-molding Mold Design

Let’s break down the three most critical areas of mold design that will make or break your project.

-

Substrate Support and Sealing:

The substrate (the first shot part) becomes an insert in the second shot mold. It must be held securely to prevent it from moving or being damaged by the pressure of the TPE injection. The "shut-off" areas, where the mold steel seals against the substrate to stop the TPE from flowing where it shouldn’t, must be precise. We often design custom locators and supports that perfectly match the substrate’s geometry, ensuring it stays locked in place. -

Gating Strategy:

Where and how you inject the TPE is critical. The gate location determines how the material flows over the substrate.- Tab Gate: Often preferred because it creates a wide flow front that gently pushes air out.

- Submarine (Tunnel) Gate: Good for automatic de-gating but can create high shear.

The goal is to gate in a way that maximizes adhesion without dislodging the insert or causing cosmetic defects on the final part. Avoid gating directly onto a small, delicate area of the substrate.

-

Venting:

This is one of the most overlooked aspects of mold design. When TPE fills the cavity, the air inside needs a place to go. If it’s trapped, it can cause incomplete filling (short shots), burn marks, and weak knit lines. Vents are very shallow channels (usually 0.01-0.02 mm deep) machined into the parting line of the mold. They are too small for the TPE to flow into but allow air to escape freely, ensuring a complete and flawless part.

By focusing on these mold design principles, you create a robust and repeatable process, turning the potential for defects and inconsistency into a reality of high-quality, perfectly bonded parts, cycle after cycle.

How Do You Optimize Processing For The Strongest Possible Bond?

You have the right materials, a smart part design, and a precision mold. Yet, your parts are inconsistent. Some have a perfect bond, while others can be peeled apart with little effort. This inconsistency is maddening and can point to a process that isn’t properly dialed in. Simply having the right tools isn’t enough; knowing how to use them is essential. Optimizing your injection molding processing parameters is the final, critical step to ensuring a strong, reliable bond every single time.

To optimize the TPE over-molding process, you must carefully control temperatures, pressures, and speeds to promote ideal bonding conditions. The most critical parameter is the TPE melt temperature; it must be high enough to reactivate the surface of the hard substrate, allowing the two materials to fuse at a molecular level. Maintaining sufficient injection pressure and hold time ensures the TPE cavity is fully packed out, maximizing surface contact. Furthermore, minimizing the time between molding the substrate and over-molding it keeps the substrate warm, which significantly enhances the chemical bond.

Think of the injection molding machine’s control panel as a chef’s stove. You can have the best ingredients (materials), the best recipe (design), and the best cookware (mold), but if your temperatures and times are wrong, you’ll ruin the dish. Processing is where we fine-tune the interaction between the TPE and the substrate. The goal is to get the TPE hot enough to create a molten interface with the substrate’s surface. This brief moment, when both surfaces are in a melt state, is where the chemical bond forms. A difference of just 10 degrees Celsius can be the difference between a weak bond and one that is stronger than the TPE itself.

Key Processing Parameters to Control

To achieve a consistently strong bond, focus on dialing in these four areas. I always start with the material supplier’s recommendations and then adjust based on the specific part and mold.

-

Melt Temperature: This is arguably the most important parameter. The TPE needs to be at the higher end of its recommended processing window. This ensures it has enough thermal energy to heat and soften the surface of the substrate upon contact, which is essential for creating an intermolecular fusion.

-

Injection Speed: A faster injection speed is generally better. It minimizes the time the molten TPE spends traveling through the runners and gate, so it arrives at the substrate surface with maximum heat. This helps prevent premature cooling and ensures a better melt bond. However, be careful not to inject so fast that it creates shear burning or flash.

-

Substrate Temperature: As we discussed, a warmer substrate bonds better. If you’re using a two-shot process, this is handled automatically. If you’re using a manual insert-molding process, over-mold the substrates as quickly as possible after they are molded. In some cases, pre-heating the substrates with infrared lamps just before loading them into the mold can dramatically improve bond strength.

-

Hold Pressure and Time: After the TPE fills the cavity, hold pressure must be applied to pack out the material and compensate for shrinkage as it cools. Sufficient hold pressure ensures intimate contact is maintained between the TPE and substrate during the critical cooling and bonding phase.

A Typical Optimization Process

| Parameter | Setting | Reason |

|---|---|---|

| Drying TPE | Yes, per supplier specs | Removes moisture which can cause splay and degrade bond quality. |

| Melt Temperature | Upper end of recommended range | Maximizes thermal energy for fusing with the substrate. |

| Mold Temperature | 25°C – 60°C | Controls cooling rate and part aesthetics. |

| Injection Speed | Fast, but not to the point of flash | Gets hot material to the bond interface quickly. |

| Hold Pressure | 40-60% of injection pressure | Ensures maximum surface contact during cooling. |

By systematically controlling these variables, you move from "hoping" for a good bond to "engineering" one. This level of process control is what separates amateurs from masters in the world of TPE over-molding.

Conclusion

Mastering TPE over-molding is not about a single secret trick. It’s about a holistic approach that meticulously integrates four key pillars: choosing chemically compatible materials, embedding mechanical locks into your part design, engineering a precision mold, and fine-tuning your processing parameters. By ensuring these elements work in harmony, you can transform the challenge of bonding soft TPE to hard substrates into a reliable, repeatable process for creating high-quality, durable, and inseparable products.