Getting inconsistent results with TPE injection molding? Perhaps your parts have defects like flash, sink marks, or a poor surface finish. These issues waste time, material, and money, hurting your production schedule and your bottom line. It’s frustrating trying to pinpoint the exact cause. The key is mastering the core process parameters: temperature, pressure, and speed. Nailing these settings is how you ensure high-quality, consistent TPE parts every time.

To master TPE injection molding parameters, you must carefully control three key areas. First, set the barrel temperature between 160°C and 220°C (320°F to 428°F), depending on the specific TPE grade. Second, use a multi-stage injection pressure, starting with a higher pressure to fill the mold and a lower holding pressure to prevent defects. Third, adjust the injection speed to a medium-to-high setting, ensuring a smooth and complete fill without trapping air. Balancing these is the secret to success.

Getting the basic settings right is a great start. But TPE is a complex family of materials. To truly achieve consistent results, you need to understand how each parameter affects the final product. Let’s break it down further, looking at each element in detail. This will help you troubleshoot problems and optimize your process for any TPE grade you work with.

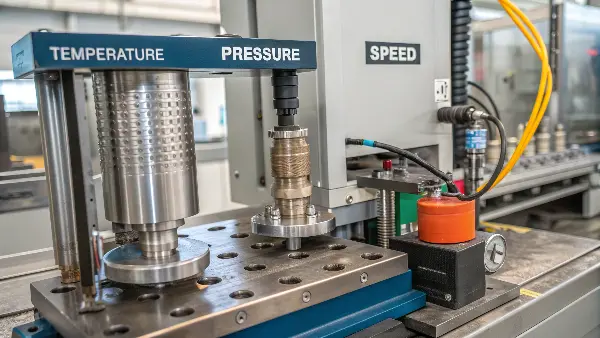

What Are the Key Parameters of Injection Molding?

Ever feel like you’re just guessing with your injection molding machine settings? You change one thing, and another problem pops up. This trial-and-error approach is inefficient and very costly. It leads to high scrap rates and unpredictable quality, which is something suppliers simply can’t afford. Focusing on the three fundamental parameters—temperature, pressure, and speed—gives you a systematic way to control the process and produce perfect parts consistently.

The key parameters of injection molding are temperature, pressure, and speed. Temperature controls the material’s flowability. Pressure, including injection and holding pressure, ensures the mold is filled completely and compensates for shrinkage. Speed, or injection rate, dictates how fast the material enters the mold, affecting surface finish and internal stress. Mastering the interplay between these three pillars is essential for achieving high-quality molded parts and an efficient, repeatable process.

To really get a handle on this, you have to see these parameters not as separate dials, but as interconnected levers. Adjusting one will almost always require a tweak to another. When I first started, I used to focus only on barrel temperature, wondering why I still got defects. It was only when I began to understand the relationship between all three that I started getting predictable results. Let’s look at each one more closely.

The Role of Temperature

Temperature is more than just how hot the plastic gets. It involves three distinct zones:

- Barrel Temperature: This is a profile, with multiple heating zones from the feed throat to the nozzle. For TPEs, you want a gradual increase to ensure a consistent melt without degradation.

- Nozzle Temperature: This is critical. It’s the last temperature the material sees before entering the mold. Keep it slightly lower than the front barrel zone to prevent drooling.

- Mold Temperature: This affects the cooling rate and surface finish. A warmer mold can improve weld line strength and give a glossier finish, but it will extend the cycle time.

Understanding Pressure Dynamics

Pressure isn’t a single setting. It’s applied in stages.

- Injection Pressure: This is the force used to push the melted plastic into the mold cavity. It needs to be high enough to fill the part completely and quickly.

- Holding Pressure (or Packing Pressure): After the cavity is filled, this lower pressure is applied to pack more material in and compensate for shrinkage as the part cools. This is crucial for preventing sink marks.

- Back Pressure: This is pressure applied to the screw as it retracts to pick up the next shot. It helps with melt homogeneity and color mixing, but too much can degrade the material.

The Impact of Speed

Injection speed determines how fast the molten plastic fills the mold. A a velocity profile—starting slow, speeding up for the main fill, and slowing down at the end—is often best. A slow speed can cause premature freezing, leading to short shots. A speed that’s too fast can cause jetting, burn marks from trapped air, or high internal stress. The right speed ensures a smooth, even fill and a high-quality surface.

| Parameter | Primary Function | Common Problems if Incorrect |

|---|---|---|

| Temperature | Controls material viscosity and flow. | Degradation, short shots, poor surface finish. |

| Pressure | Fills the mold and compensates for shrinkage. | Flash, sink marks, short shots, warp. |

| Speed | Determines fill rate and material behavior. | Jetting, burn marks, weld lines, internal stress. |

What Is the Recommended Processing Temperature for TPE?

Are your TPE parts coming out brittle or with flow marks? The wrong processing temperature is often the culprit. Using a temperature that’s too low leads to incomplete filling, while one that is too high can degrade the material, causing discoloration and a loss of properties. This can lead to entire batches being rejected by your client, which is a situation I’ve seen happen to even experienced shops. Getting the settings right from the start is crucial.

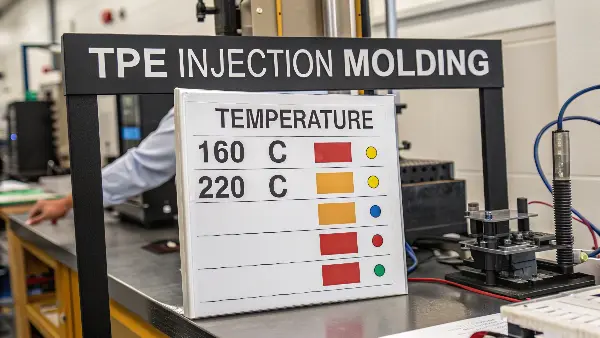

The recommended processing temperature range for TPE injection molding typically falls between 160°C and 220°C (320°F to 428°F). However, this is just a general guideline. The exact temperature depends heavily on the specific TPE grade, its hardness (durometer), and the part’s design. Always start with the manufacturer’s data sheet recommendations. For softer TPEs, use the lower end of the range, and for harder grades, use the higher end. A systematic approach to finding the optimal temperature is key.

Simply setting the machine to a single number within this range won’t work. The temperature needs to be managed across different zones of the machine. I always tell my team to think of it as creating a smooth temperature "ramp" for the material. This prevents thermal shock and ensures the TPE is perfectly melted by the time it reaches the mold. It’s a bit of an art, but there’s a science to it.

Barrel Temperature Profile

The barrel is where the TPE pellets are melted and conveyed. It’s divided into several heating zones, usually a rear, middle, and front zone. A typical profile for a general-purpose TPE might look like this:

- Rear Zone (near the hopper): 160°C – 180°C (320°F – 356°F)

- Middle Zone(s): 180°C – 200°C (356°F – 392°F)

- Front Zone: 190°C – 210°C (374°F – 410°F)

This gradual increase helps the material melt evenly. Starting too hot in the rear can cause premature melting and bridging in the feed throat, which is a real headache to clear.

Nozzle and Mold Temperature

The nozzle temperature is the final checkpoint before injection. It should generally be set at or slightly above the front zone temperature, but be careful. If it’s too high, the TPE can drool out between shots. I usually set it about 5°C lower than my target melt temperature to keep things under control.

Mold temperature is equally important. For TPEs, a mold temperature between 30°C and 60°C (86°F to 140°F) is common. A warmer mold helps the material flow better, improves the surface finish, and strengthens weld lines. But, it also increases the cooling time, which slows down your cycle. You have to find the right balance for your specific part and production needs. Always start with the material supplier’s recommendations and adjust from there.

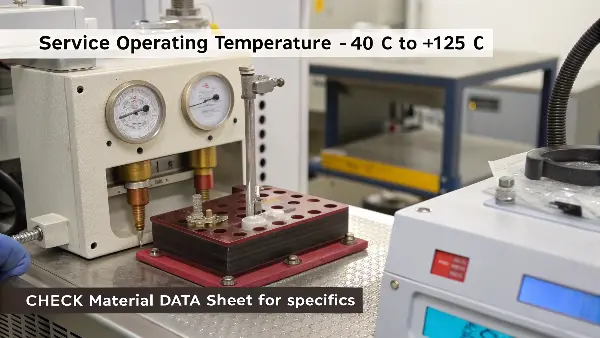

What Is the Service Operating Temperature of TPE?

You’ve perfectly molded a TPE part, but will it survive in its final environment? Thinking only about a material’s processing temperature is a common mistake. If the part gets exposed to heat or cold beyond its limits, it can fail spectacularly, leading to product recalls and a damaged reputation. This is why understanding the service temperature is just as important as knowing how to mold it correctly.

The service operating temperature of a TPE part is the range in which it maintains its physical properties, like flexibility and strength, during use. This typically ranges from -40°C to +125°C (-40°F to +257°F). However, this varies significantly between different TPE families. For example, a standard TPE-S (styrenic block copolymer) might be limited to 100°C, while a high-performance TPE-V (vulcanizate) can withstand higher temperatures. Always check the material data sheet for the specific grade’s heat deflection temperature (HDT) and brittle point.

Many years ago, a client came to me with a problem. They had designed a beautiful soft-touch handle for a kitchen utensil. The parts looked great and felt perfect. But after a few runs through a dishwasher, the TPE handles became sticky and deformed. The problem wasn’t the molding; it was the material selection. They had chosen a TPE without considering its upper service temperature limit. We switched to a more heat-resistant grade, and the problem was solved. This taught me a valuable lesson: always match the material to the end-use environment.

Understanding Temperature Limits

There are two key temperatures to consider for a TPE part’s service life:

- Upper Temperature Limit: This is often related to the Heat Deflection Temperature (HDT) or Vicat Softening Temperature. Above this point, the TPE will soften, lose its structural integrity, and deform under load.

- Lower Temperature Limit: This is called the brittle point or glass transition temperature. Below this temperature, the flexible TPE becomes hard and brittle, and it can easily crack or shatter upon impact.

Comparing TPE Families

Different types of TPEs are engineered for different environments. This is why you can’t just ask for "TPE"; you need to be specific.

| TPE Family | Typical Continuous Use Temp. Range | Key Characteristics |

|---|---|---|

| TPE-S (SEBS, SBS) | -40°C to 110°C (-40°F to 230°F) | General purpose, good feel, cost-effective. |

| TPE-O (TPO) | -40°C to 120°C (-40°F to 248°F) | Good chemical resistance, common in automotive. |

| TPE-V (TPV) | -40°C to 135°C (-40°F to 275°F) | Excellent heat and oil resistance, rubber-like. |

| TPE-E (COPE) | -40°C to 140°C (-40°F to 284°F) | High strength, good flex fatigue resistance. |

| TPE-U (TPU) | -40°C to 125°C (-40°F to 257°F) | High abrasion resistance, strong and durable. |

| TPE-A (COPA) | -40°C to 130°C (-40°F to 266°F) | Good heat resistance, ideal for under-hood apps. |

When you’re selecting a TPE, look beyond the price and processing ease. Always ask: "Where and how will this part be used?" Considering the maximum and minimum temperatures it will experience is a non-negotiable step in the design process.

What Is the Difference Between TPE and TPU Injection Molding?

Are you struggling to choose between TPE and TPU for your next project? They both seem similar—they are both flexible, durable materials. But treating them the same in the injection molding press will lead to problems. This confusion can result in choosing the wrong material or using incorrect processing parameters, causing part defects and wasting valuable machine time. Understanding their key differences is essential for success.

The main differences between TPE and TPU injection molding lie in their material properties and processing requirements. TPU (Thermoplastic Polyurethane) is generally harder, more abrasion-resistant, and requires higher processing temperatures and pressures than TPE (Thermoplastic Elastomer). TPE is softer, more flexible, and often processes at lower temperatures. Critically, TPU is highly hygroscopic and must be thoroughly dried before molding to prevent defects, a step that is less critical, but still recommended, for many TPE grades.

I remember a project where we were molding protective boots for an electronic device. The initial design called for TPE. The molding went smoothly. Later, the client requested a more rugged version that could withstand more scuffs and scrapes. We switched to a TPU grade. Immediately, we started seeing splay and bubbles on the part surface. My less-experienced operator was baffled because he used the same machine settings. The problem? We hadn’t dried the TPU properly. It had absorbed moisture from the air, which turned to steam in the hot barrel. It was a classic mistake that highlights how you can’t just swap these materials without adjusting the entire process.

Pre-Processing: The Drying Difference

This is the most critical difference.

- TPU: It’s a moisture magnet. It absolutely must be dried in a desiccant dryer for 2-4 hours at around 80-110°C (175-230°F) before processing. The target moisture content should be below 0.05%. If you skip this, you will get splay, silver streaks, and brittle parts.

- TPE: Most TPE grades are not as sensitive to moisture. Some don’t require drying at all. However, for certain grades, especially softer ones or if they’ve been stored in a humid environment, drying for 1-2 hours at 60-80°C (140-175°F) is good practice to ensure a perfect surface finish.

Processing Parameters

Here’s how their molding settings generally differ:

| Parameter | TPE (General) | TPU (General) |

|---|---|---|

| Melt Temperature | 160°C – 220°C (320°F – 428°F) | 190°C – 230°C (374°F – 446°F) |

| Mold Temperature | 30°C – 60°C (86°F – 140°F) | 20°C – 70°C (68°F – 158°F) |

| Injection Pressure | Moderate | High |

| Back Pressure | Low to Moderate (0.3 – 1 MPa) | Moderate to High (0.5 – 2 MPa) |

| Shrinkage | 1.2% – 2.5% | 0.8% – 1.8% |

TPU requires more energy to melt and push into the mold due to its higher viscosity. This means higher temperatures and pressures are needed. TPEs, being softer, flow more easily. Because of their different shrinkage rates, you generally cannot use the same mold for a TPE part and a TPU part and expect them to have the same final dimensions. Choose your material first, then design the mold around it.

Conclusion

Mastering the injection molding of TPE materials comes down to controlling the core parameters of temperature, pressure, and speed. It’s also vital to understand the difference between processing temperature and the final part’s service temperature. By carefully selecting the right TPE grade and fine-tuning your process based on data sheets and real-world testing, you can move from guesswork to a reliable, repeatable method for producing high-quality parts every single time.