Manual assembly can be time consuming and error ridden as well as costly. You require a simplified solution that has components tied together.

Insert molding is more economical than conventional assembly processes because it helps cut cost on labor, make parts more consistent and increases product life. It reduces several manufacturing operations into a single operation and the overall costs of production are frequently reduced, particularly in high-volume quantities, whereas the initial costs in terms of tooling may be high.

My entry into the mold industry led to much confusion in decision-making on the manufacturing process many companies had. It is a huge move; which influences things related to your budget as well as to the final quality of your product. So, let us dissect insert molding and compare it to the other alternatives to understand what exactly makes it the right choice of your next project. We will discover what it is, its advantages and disadvantages and compare it with other similar methods.

Then What is Insert Molding?

You have heard the phrase insert molding but you are not really sure what it implies to your parts? It also sounds fancy but it is an ingenious method of merging. Being conversant with it will open new design frontiers to you.

Insert molding Plastic insert molding Assemblies can be made through plastic injection molding technique in which a completed component is typically metal or a different plastic, and it is placed into a mold cavity. Liquid plastic is injected around this "insert" resulting in a one piece, one component. This causes the secure attachment of the insert to the plastic.

Dive deeper Paragraph:

Insert molding is a fascinating technique that I’ve seen solve many design challenges. Think of it like this: you have a component, say a metal screw or a ceramic pin, that needs to be part of a larger plastic piece. Instead of making the plastic part and then manually attaching the screw later, insert molding does it all in one go.

Here’s a simple breakdown of the process:

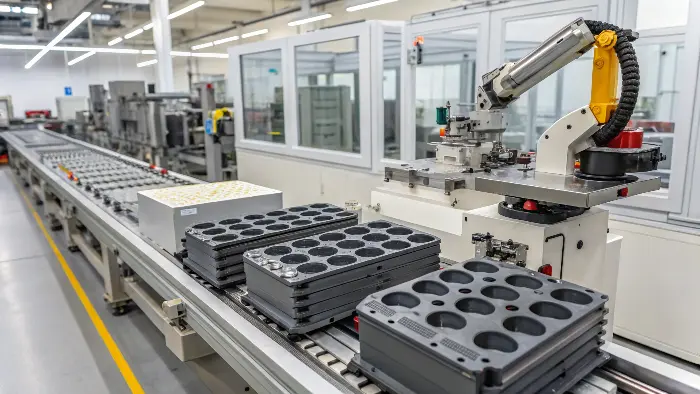

- Insert Placement: The pre-made insert (like a threaded bushing, a shaft, or an electrical contact) is carefully placed into the mold. This can be done manually by an operator or automatically by a robot, depending on the production volume and complexity.

- Mold Closure: The mold closes, holding the insert securely in its designated position.

- Injection: Molten plastic resin is injected into the mold cavity, flowing around the insert.

- Cooling and Solidification: The plastic cools and solidifies, forming a strong bond with the insert.

- Ejection: The mold opens, and the finished part, with the insert now an integral component, is ejected.

The process is excellent in the production of sturdy pieces with improved characteristics. To take such an example, you can design plastic knobs that are reinforced with metal to the threads that are embedded on the knob itself or even electrical connectors that have pins that are molded directly into the plastic case. It removes secondary assembly processes such as screwing, gluing or welding.

This reduces time and has the potential to enhance the general quality and reliability of the end product. I recall one customer who had a problem with loose metal inserts in their plastic handles, a move to insert molding cured the problem entirely and eliminated their assembly aches and pains.

How Does Insert Molding Differ From Overmolding?

Not sure of insert molding or overmolding? These are similar in their sounding, and two mixes the materials, yet they are used with different purposes. The difference is also important as it helps in selecting the appropriate process in your product.

Insert molding involves placing a separate, pre-existing component (the insert) into a mold before injecting plastic around it. Overmolding, on the other hand, involves molding a layer of material (often a soft thermoplastic elastomer) over an already existing part, which acts as the substrate.

Dive deeper Paragraph:

Both insert molding and overmolding are fantastic ways to create multi-material parts, but they achieve this in slightly different ways and for different reasons. I’ve used both extensively in my career, and the choice really depends on the end goal for the product.

Let’s look at the core differences in a simple table:

| Feature | Insert Molding | Overmolding |

|---|---|---|

| Core Process | Plastic is molded around a pre-placed insert. | A material is molded onto an existing substrate part. |

| Insert/Substrate | Insert is often metal, ceramic, or a different plastic. | Substrate is typically a rigid plastic or metal part. |

| Main Purpose | Integrate functional components (threads, pins), add structural strength, reduce assembly. | Add soft grip, sealing, aesthetics, or dampen vibration. |

| Timing | Insert is placed before the main molding cycle. | Substrate is molded first, then moved to another mold or station for the overmold. |

Consider the insert molding as the process of embedding something to the plastic. One of the examples I may refer to is a screwdriver handle. The metal shaft (which is the insert) is set in the mold and then the plastic handle is formed around it thereby making one solid piece.

Overmolding resembles skinning of an existing part more. Take the case of a toothbrush: the hard plastic handle (the substrate) is produced first. The grippy material that you can touch on the handle is then pressed on particular parts of that handle. This is overmolding. The first component is complete even before the second content is layered. There are occasions that the substrate even has been produced through an entirely different process and is then taken to the injection molding machine to have the overmolding process done. Therefore, though both involve production of one component consisting of several materials, insert molding aims at encapsulating a specific component, whereas overmolding aims at draping a layer on a surface.

Considerations Before Insert Molding

The following are some of the factors that should be considered

The Inserts Types

Before inserting molding, there are factors that must first be put into consideration and these are the type of insert. You can choose whatever insert to use, but it must be able to endure the extremes of temperature and pressure that are usually encountered to do the process.

Reduce the distinction between metal parts insertions

The difference between the metal insert molding and the molten material is one other additional thing that would be considered before insert molding. In addition to that, reducing the distance between objects improves the reliability of the molding of the composite product of metal insert.

Choose Suitable Molding and Resin Condition

When inserting molding it is highly recommended to choose the appropriate resin and molding conditions. This selection also applies in handling easily broken products such electrical parts, glass and coils. This kind of resins is the best to seal and fixate.

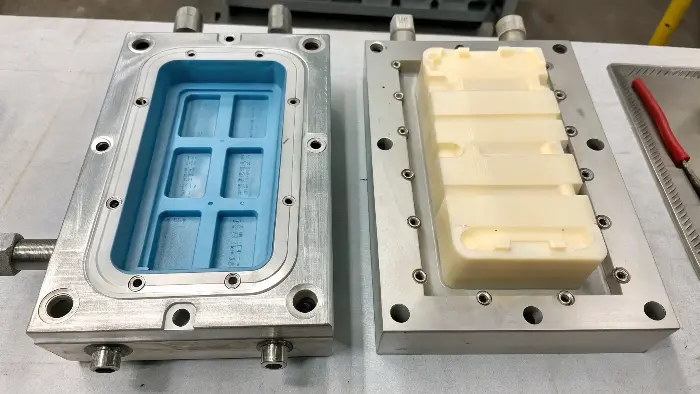

Right Mold Selection

The insert molding mold is not just making the shape of the molten material. It is also useful in keeping the insert in position through insert molding process. It should thus be noted that insert type injection mold should be used which holds the inserts during the process.

Insert Location

The insert positioning dictates the forces that would be acting on the insert in the long term. In addition, location should consider the purpose of insert and plastic required to fix its position.

The Cost

An important factor to consider is on cost-sensitive parts. The price consists of the price of the inserts as well as one of contracting an operator. The other cost factor involves knowing the increment in piece price that the insertion of inserts would bring.

Production Volume

Depending on volumes of production, the difference will be between a manual or an automated loading technique. Therefore, the process of making the correct loading requires having a cost-benefit analysis and having knowledge of the production requirements

What About Overmolding Versus 2K Molding – Are They Different?

As now we have mentioned overmolding, you may have heard of 2K molding, Is it overmolding using different terminology or a different thing? This is confusing, particularly in planning when you are involved in production and attempt to be accurate in the usage of words.

The term overmolding generally refers to the process of molding of one material over another (2K molding, two-shot molding), where the leading material is a plastic resin The two-shot molding use two different plastic resins injected into the same mold in a sequential cycle-usually in a rotary-type mold.

Dive deeper Paragraph:

This is a common point of confusion I encounter, and it’s important to clarify. "Overmolding" is the broader concept. You can overmold a material onto a part that was made hours, days, or even weeks before, perhaps even in a different factory. The substrate part is loaded into a mold (manually or automatically), and the second material is molded over it.

2K molding, also known as two-shot molding or multi-shot molding (if more than two materials are involved), is a more specialized and often more integrated version of overmolding. Here’s how it typically works in a dedicated 2K machine:

- First Shot: The first material (e.g., a rigid plastic) is injected into a mold cavity to create the substrate.

- Mold Repositioning: The mold then rotates, or a core slides, to a new position. This aligns the first shot (which is still in the mold) with a new cavity configuration.

- Second Shot: The second material (e.g., a soft TPE) is injected from a second injection unit into the new cavity, flowing onto or around the first shot.

This all happens in one machine, in one continuous, automated cycle.

Key distinctions to remember:

- Process Integration: 2K molding is highly integrated, using a single specialized machine with multiple injection units. Traditional overmolding can use separate machines or manual loading between shots.

- Cycle Time: 2K molding is generally faster for high volumes because it’s a continuous process within one machine cycle. This can lead to significant cost savings in large production runs.

- Bonding: The bond between materials in 2K molding can be very strong, especially if compatible materials are used. The first shot is often still warm and chemically receptive when the second shot is applied, promoting excellent adhesion.

- Tooling Complexity & Cost: 2K molds are significantly more complex and therefore more expensive than single-shot molds or even some simpler overmolding setups. The precision required is very high.

So, all 2K molding is a form of overmolding, but not all overmolding is 2K molding. If you’re making a simple soft-grip handle by manually placing a rigid core into a second mold for the soft material, that’s overmolding. If you’re using a sophisticated machine that injects both the rigid core and the soft grip in a single, automated cycle using a rotating platen, that’s 2K molding. I’ve seen 2K molding produce some incredibly intricate and high-quality parts, like multi-colored automotive taillight lenses or complex medical device components, where precision and material bonding are absolutely critical.

What Are the Downsides of Choosing Insert Molding?

While insert molding offers many benefits, it’s not always the perfect solution for every project. Are there hidden costs or complexities you should be aware of? It’s important to be aware of the possible disadvantages before beginning this process.

The main disadvantages of insert molding include higher initial tooling costs due to more complex mold designs, potentially slower cycle times if inserts are manually loaded, and the risk of insert damage or misplacement during molding. Material compatibility between the insert and the plastic is also a critical consideration.

Dive deeper Paragraph:

Insert molding is a powerful technique, but like any manufacturing process, it has its trade-offs. I always advise clients to weigh these carefully against the benefits for their specific application.

Here are some key disadvantages to consider:

- Higher Initial Tooling Costs: Insert molding is logically more complicated than regular injection molds. They should have accurate features so that they can locate and safely retain the inserts in the process of injecting the molten plastic at high pressure. Such design and manufacturing complexity implies that the mold itself is going to be more expensive. This initial cost may be high particularly in case of small production volumes.

- Potentially Slower Cycle Times: If inserts need to be loaded into the mold manually by an operator, this adds time to each cycle. While automation (using robotics) can speed this up for high-volume production, it adds another layer of cost and complexity to the production setup. This can sometimes offset the labor savings gained from eliminating secondary assembly steps.

- Risk of Insert Damage or Misplacement: Inserts must be placed precisely. They also need to be robust enough to withstand the forces of mold clamping and plastic injection. If an insert is misplaced, it can lead to scrapped parts or, even worse, damage to the mold, which is a costly repair. Delicate inserts might get crushed, bent, or deformed by the plastic flow.

- Material Compatibility: The plastic resin and the insert material must be compatible. A key factor here is differential thermal expansion and contraction. If the materials expand or shrink at vastly different rates as they cool, it can lead to internal stresses, poor adhesion between the plastic and the insert, or even cracking of the plastic.

- Design Constraints: The need to accommodate the insert can sometimes place limitations on the part design. For instance, wall thicknesses around the insert need to be sufficient to ensure a good bond and structural integrity. The geometry of the insert itself might also dictate certain design features.

- Scrap Rate Considerations: If an insert is faulty or incorrectly placed, the entire molded part (both the plastic and the valuable insert) might become scrap. This can be more costly than if components were assembled separately, where a faulty component could potentially be identified and replaced more easily before final assembly.

I remember a project where we tried to insert mold very thin metal foils. We had a tough time preventing them from wrinkling under the injection pressure. It took several mold revisions and very careful process control to get it right, which added to the development time and cost. So, while the benefits of insert molding are often compelling, it’s essential to anticipate and plan for these potential challenges.

What’s the Difference Between ISO and ANSI Inserts When We Talk About Molding?

On threaded parts, you may be told of the ISO or ANSI specification on inserts. Is this so regarding process of insert molding itself, or only its components? Learning about these standards may influence your sourcing and design decisions.

International Organization of Standardization (ISO) and American National Standards Institute (ANSI) are organizations that develop guidelines on different components such as threaded inserts. They vary in their specifications i.e. thread dimensions (metric and inch) and tolerance. The selection between the two may influence insert availability, cost and compatibility with mating parts.

Dive deeper Paragraph:

So when we speak of ISO and ANSI inserts to insert molding, then we mean the so-called standardized inserts, such as threaded inserts or bushings which are intended to be injection molded into the plastic part. The standards do not govern the insert molding process itself but the specification of inserts you may choose to use in the process.

Here’s why this distinction matters for your project:

- Dimensional Standards: ISO standards typically define metric sizes (e.g., M3, M4, M5 threads), which are common globally. ANSI standards often define inch-based sizes (e.g., 4-40, 1/4-20 Unified National Coarse/Fine threads), which are prevalent in the USA. The standards cover thread pitch, major and minor diameters, and tolerances.

- Availability and Sourcing: The prevalence of ISO or ANSI standard inserts can vary by region and supplier. This can affect how easily you can source them and potentially their cost. Using a widely available standard can give you more supplier options and potentially better pricing.

- Compatibility with Mating Parts: This is often the most critical aspect. The insert must be compatible with the screws or other components that will be used in the final assembly. If your product is designed to use an M3 screw, you absolutely need an M3 (ISO) threaded insert. Using an ANSI insert would lead to assembly problems.

- Design Integration into the Mold: While the molding process remains the same, the design of the mold cavity pocket that holds the insert will need to precisely match the outer dimensions and features of the chosen insert (whether it’s an ISO or ANSI type). The features on the insert designed to grip the plastic (like knurls, grooves, or undercuts) are also important for a strong bond. These gripping features can vary between manufacturers even for inserts that meet the same basic ISO or ANSI thread standard.

- Cost of Inserts: The cost of the inserts themselves can also vary based on the standard, material, and manufacturer. This is a direct component cost that feeds into your overall product cost analysis.

As an example, where I am developing a product to be marketed globally I may incline towards the use of the ISO metric inserts due to the universal wrapper it has. Assuming that the product is meant mainly to be sold by US, and will have to work with other ANSI-sized parts, ANSI inserts may become the obvious solution. Company standards are some of the pre-existing ones that may drive the decision; there may be certain customer needs also. It is not necessarily that there is a differences in the way insert molding machine works, it is rather a way of assuring that the component you are embed becomes that required in the engineering and compatibility along with the cost required in the final product functioning and commerce.

Conclusion

In the end, determining whether or not insert molding is appropriate to you is a matter of what options are more important: the ability to minimize the labor used in assembly and enhance the robustness of the parts versus facing increased tooling and possibly a reduction of cycle time. The most cost-effective decision can be made by accurately analyzing your own product, the volume in which that specific product is being made, as well as the complexity of design that your own product will be going through.