Do you struggle with surprise defects, expensive tool changes, and production downtime in your production process? These problems can devour your profits and schedules. Mold flow analysis is a valuable tool to foresee and fix these problems before they even reach the factory floor.

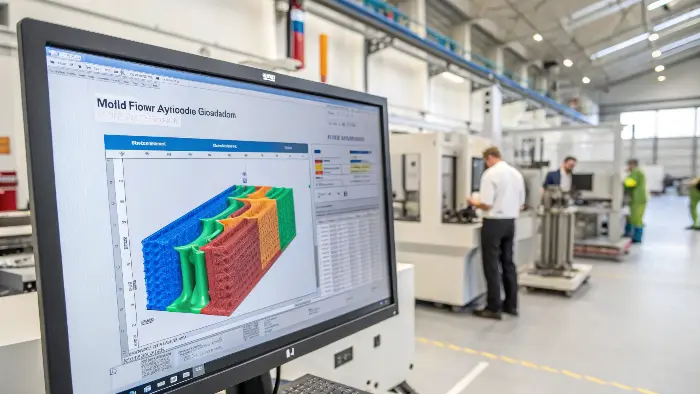

Mold flow analysis is a computer simulation method with special software to predict and optimize injection molding. It allows manufacturers to understand how plastic resin will flow into and fill up a mold. This allows design improvement, prevention of defects like weld lines or air traps, and optimization of gate location, thereby improving product quality and reducing production cost.

Understanding that mold flow analysis can help is the first step. But to truly leverage its power, you need to know what it really is, what makes it tick, and how it fits into the bigger picture of making products. Let’s explore these aspects so you can see how it can make a real difference in your manufacturing outcomes.

What Exactly is Mold Flow Analysis and Why Should You Care?

Do you ever get the sensation of flying by the seat of your pants in designing a mold, then discover there are unforeseen issues in production? Uncertainty can result in expensive trial-and-error, putting your product launch behind schedule. Mold flow analysis can eliminate much of the guesswork, allowing you to have confidence in your designs.

Mold flow analysis is a computer simulation technique that predicts the molten plastic behavior as it is injected into a mold cavity. It simulates a virtual image of the filling, packing, and cooling operations. It helps engineers to design parts and molds more optimally, anticipate and prevent potential defects like sink marks or warpage, and ultimately improve the quality and manufacturability of plastic parts.

So, what does this translate into in the real world? Let’s say you’re designing a new plastic enclosure, like a lot of the work Jacky, our product designer, does. Mold flow analysis software allows you to "see" inside the mold before any steel is ever cut for it, which is extremely expensive. You can see that the plastic fills all the nooks and crannies. I remember one project early in my career where we didn’t want to take the time to do a proper analysis. We had severe warpage issues that cost us a lot to repair and delayed the product launch weeks. What that taught me was the true value of this simulation.

Mold flow analysis helps you with:

- Predict Defects: It is able to identify possible flaws like:

- Weld lines: Where two fronts of flow intersect.

- Air traps: Pockets of air which cannot escape.

- Sink marks: Depressions on the surface.

- Warpage: Warping of the part on cooling.

- Optimize Design: You can attempt different:

- Gate locations: Where the plastic enters the cavity.

- Runner systems: Routes that supply plastic to the gates.

- Wall thicknesses: Consistent filling and cooling.

- Optimize Processing Conditions: It helps to establish best:

- Filling time.

- Injection pressure.

- Melt and mould temperatures.

By catching these issues early, you save an enormous amount of time and money on physical testing and tool changes. It’s making informed decisions early on in the design cycle.

What Key Parameters Drive a Successful Mold Flow Analysis?

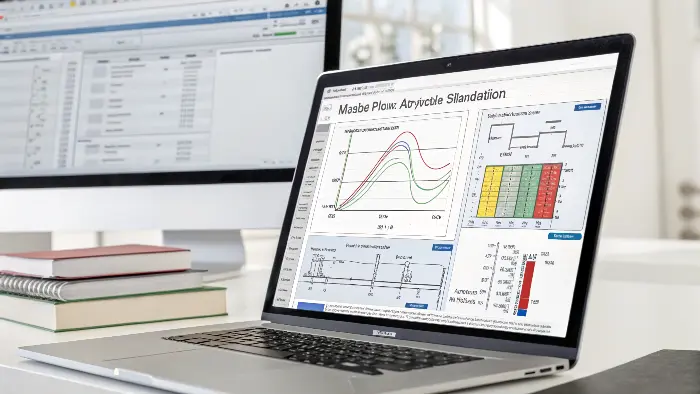

Are your mold flow analysis results not giving you the right predictions that you need? Incorrect results will lead to you making the wrong design choices. The success of any mold flow analysis depends significantly on the correctness and quality of the input parameters.

Proper inputs to flow simulation in a mold are full material properties (such as viscosity and thermal response), correct processing conditions (injection pressure/speed, melt/mold temperature, and packing parameters), and correct mold geometry (part geometry, runner/gate system, and cooling channels). Input of proper and full data for these inputs is strictly necessary to obtain correct and useful simulation results.

It’s critically important that these parameters are accurate. I remind my clients each time that the analysis is only as good as the data you feed it with. If you’re feeding it generic material data for a very specific polymer, you can’t anticipate good results. It’s like trying to bake a complicated cake with an approximation of the ingredients and oven temperature.

Let’s break down these critical parameters:

-

Material Properties: These are probably the most critical set of data.

- Rheological Data: This refers to a description of the way the plastic flows. It consists of viscosity measurements at various shear rates and temperatures. Without good viscosity data, simulation of how the plastic fills the mold will be incorrect.

- Thermal Properties: They are the specific heat (the amount of energy needed to heat the plastic), thermal conductivity (the way it conducts heat), and the ejection temperature (when it is hard enough to be ejected from the mold). They affect cooling time and warpage.

- PVT (Pressure-Volume-Temperature) Data: This is the manner in which plastic density varies with respect to pressure and temperature. It’s extremely critical in the sense of accurately forecasting shrinkage and warpage. I’ve had cases where accurate PVT data made a tremendous amount of difference in forecasting sink marks.

-

Processing Conditions: These are the conditions you’d set on the actual injection molding machine.

*Yes- Melt Temperature: The temperature of the plastic when it is introduced into the mold.

- Temperature of the Mold: Surface temperatures of the mold.

- Injection Speed/Profile: The speed at which the plastic is injected. Sometimes a non-linear speed profile is used.

- Packing Pressure and Time: Pressure applied after mold filling to compensate for shrinkage.

- Cooling Time: The length of time which the part is in the mold to harden.

-

Geometric Parameters: Your computer representation of your mold and part.

- Part Geometry: The 3D model of the part, including all features and wall thicknesses.

- Feed System: The sprue, runners, and gate design. Their shape and size are very important to flow.

- Cooling System: The form and quantity of cooling channels in the mold. This is crucial in the computation of cooling efficiency and warpage.

Having exact information on all these parameters, generally from material suppliers or dedicated lab testing, is very important to a simulation that is a true representation of reality.

How is Mold Flow Analysis Improving Mold Design?

Mold flow analysis is a robust process that allows engineers to identify some of the design problems early on in the process. It also allows for earlier part design optimization and reduced retooling cost later in the process.

Reduction in Part Warping

Differential wall thickness parts injection molding will introduce unwanted warpage under pressure. Such issues can be identified and resolved through mold flow analysis before a mold is created.

Facilitates Uniform Filling of Mold Cavities

Mold flow analysis ensures an equal filling of mold cavities. Therefore, it minimizes the risk of air being trapped between mold cavities. It also minimizes surface defects such as sink marks and weld lines. It also assists engineers in determining the optimal gate location position to aid continuous and uniform flow of resin during the mold.

It Facilitates Comparison of Physical and Chemical Properties before Production

Mold flow analysis online offers engineers the ability to compare the chemical and physical characteristics of different material manufacturing materials prior to production. It enables engineers to select an appropriate material to match the composition of the part to its intended application.

Which Mold Flow Analysis Software is the Right Fit for Your Needs?

Lost in the ocean of software choices for mold flow analysis? Wasting money and learning a new tool’s ropes if you buy the wrong one can be a frustrating experience. Understanding the top software and their specialties can give you a solid basis to make an informed decision.

Autodesk Moldflow, Moldex3D, and SOLIDWORKS Plastics are among the best and most highly respected mold flow analysis software programs. "Best" is actually a function of the complexity of your parts, your budget, your staff’s capabilities, and how well it will work with your existing CAD systems. Test driving before you buy in the sense of test-drives on trial versions and considering what problems you most frequently need to solve is a good strategy.

Obtaining the right software is a very important decision. When I set up CKMOLD originally, I was aware that having access to, and familiarity with, quality analysis software was going to be completely key to helping my customers. There is no simple solution. For a consumer electronics design engineer like Jacky, who is already familiar with CAD, the choices might be other than for an analysis expert team designing very sophisticated automotive parts.

Here’s a brief glimpse at some popular choices:

- Autodesk Moldflow: Generally the norm, particularly for sophisticated analyses. It’s very detailed and provides you with a deep understanding of everything about the injection molding process. It’s got a bit of a learning curve but is extremely powerful. I’ve utilized Moldflow on countless tough projects, and the analysis level is amazing.

- Moldex3D: A very powerful and accurate tool, well-known for its solid 3D meshing and advanced simulations. It is also very well-suited for challenging parts and challenging analysis, being nearly as good as Moldflow.

- SOLIDWORKS Plastics: This is a great option for designers and engineers who are already familiar with SOLIDWORKS CAD software. It’s highly integrated, so it’s less complicated to transition from design to analysis. It might not carry all the functionality of Moldflow or Moldex3D, but it’s very capable of handling a great deal of the common injection molding issues and has a less steep learning curve. This would be a great option for Jacky to double-check his designs easily.

- Other Options: Other programs include Simpoe (now a subsidiary of Dassault Systèmes) and specialist packages.

When selecting software, consider:

- Precision Requirements: Do you require precise pinpoint accuracy in your applications?

- Part Complexity: Do you have simple parts or very complex geometries?

- Simple to Use vs. Advanced Features: Do you require something easy to use, or do you require advanced analysis features?

- CAD Integration: How well does it integrate with your central design software?

- Cost: Software licenses can be very expensive. My suggestion is usually to identify your most common analysis needs and then try out a few options with tests or demos.

How Does Mold Flow Analysis Fit into the Overall Molding Process in Manufacturing?

Do you ever consider mold flow analysis as an independent process, separate from the actual manufacturing? Not knowing where it stands in the entire production process can lead to you not being utilizing it to its full potential. Mold flow analysis performs best when it is integrated within the manufacturing cycle.

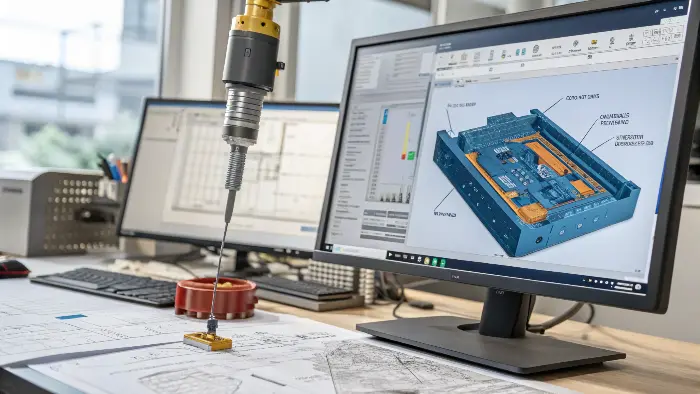

There are several steps in the injection molding process: mold and part design, plastic material preparation, injection molding machine preparation, injection of the plastic melt into the mold, cooling and solidification, part ejection, and any subsequent post-processing. Mold flow analysis is used most often in the product design and pre-production phases in an attempt to optimize these subsequent steps to the utmost possible degree and prevent problems ahead of time.

In order to get a feel for where mold flow analysis is applied, it’s helpful to very briefly illustrate what a typical injection molding process is like. I’ve spent many hours in mold shops watching it happen, and it’s a fascinating dance of power and precision.

The basic steps are:

- Clamping: The two halves of the mold are clamped tightly together by the molding machine.

- Injection: Plastic material in molten state injected under pressure into the mold cavity.

- Packing/Holding: Once the cavity is filled, pressure is again applied to pack in even more material, with allowance for shrinkage when the plastic solidifies.

- Cooling: The material hardens in the mold. This is usually the most time-consuming step in the process.

- Mold Opening: The mold halves are opened.

- Ejection: The solidified part is pushed out of the mold.

So where does mold flow analysis find its place?- At Part and Mold Design (Pre-Production): It is here in its sweet spot.

- Part Design Validation: It can be used by designers such as Jacky to validate whether their part design will be moldable or not. For instance, are there thin walls that won’t fill? Are there any features that might lead to sink marks?

- Mold Design Optimization: This is where it really shines for mold makers. It helps identify the optimal gate location and gate size, create efficient runner systems for maximum material utilization, and create efficient cooling channel configurations for minimum cycle time and warpage. I have used it to decide between a single gate and multiple gates for a large part and improved fill balance considerably.

- Process Parameter Optimization (Pre-Production): Even prior to the first trial shot, analysis can provide optimal injection speeds, pressures, and temperatures, minimizing the trial-and-error required on the machine.

- Troubleshooting (In Production – less often for full re-simulation but lessons are transferable): When an in-production mold is delivering defective parts, analysis can be used periodically to model the present defective process and experiment with potential solutions in a virtual setting. By including mold flow analysis early on, you ensure subsequent steps in the molding process are smoother, faster, and with fewer costly surprises. It closes the loop between design intent and manufacturing reality.

Why Mold Flow Analysis Needs to Become an Engineering Mainstream Tool?

Mold flow analysis is no longer a "nice-to-have" but an essential tool in the arsenal of the engineer for competitive, high-quality injection molded parts. By investing a relatively modest amount of time and budget early on, companies can reap long-term benefits in terms of:

- First-time-right tooling

- Less engineering changes (ECOs)

- Rapid time-to-market

- Lowered manufacturing risk

- Improved product quality

With increasing pressure to cut back on development time and improve part performance, engineering teams that employ mold flow analysis from the onset of the design process are consistently beating their competitors.

Conclusion

Mold flow analysis is a vital simulation tool in modern product manufacturing. It empowers designers and engineers to predict how plastic will behave during injection molding, allowing for proactive optimization of part and mold designs. By identifying potential issues like air traps or uneven filling early, it significantly reduces costs, shortens development time, and ultimately leads to higher quality products and a more efficient manufacturing process.