Struggling with defects like flash or sink marks in your TPE parts? These issues often point back to a mold design that doesn’t account for the unique properties of thermoplastic elastomers. This can lead to increased cycle times, high scrap rates, and ultimately, lost profits. Mastering a few key design principles can transform your TPE molding process from a constant headache into a reliable, efficient operation.

Designing a successful mold for TPE materials hinges on three critical areas. First, precise gate location is essential to control material flow and prevent cosmetic defects. Second, an optimized cooling system ensures uniform temperature control, which minimizes warpage and shrinkage. Finally, a robust ejection strategy is needed to handle the flexible, often sticky nature of TPE and prevent part damage during demolding. Getting these three elements right is fundamental to achieving high-quality results consistently.

Getting these three elements right is where the art of mold making meets science. It’s not just about creating a cavity; it’s about controlling how the material behaves from the moment it’s injected until the finished part is in your hand. This requires a deep understanding of the material itself and how it interacts with steel.

Let’s break down each of these critical areas one by one. By the end, you’ll have a clear roadmap to turn TPE molding challenges into your competitive advantage.

How Does Gate Location Affect TPE Molding Quality?

Have you ever seen an otherwise perfect TPE part ruined by a visible, ugly gate mark? Or maybe you’ve struggled with parts that don’t fill completely, leaving you with scrap. The placement and type of your gate are often the hidden causes of these costly frustrations. Getting it wrong leads to wasted material and time, but mastering gate location can dramatically improve your part’s appearance and structural integrity.

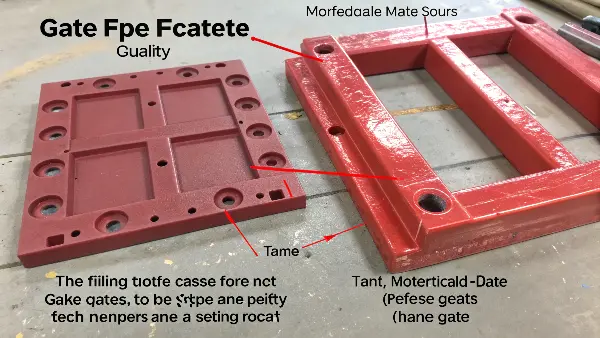

Proper gate location for TPE molding is crucial for controlling flow, appearance, and part integrity. The best location ensures a balanced fill pattern, minimizes shear stress on the material, and avoids placing the gate in cosmetically sensitive or high-stress areas. Common types like fan gates or tab gates are chosen based on the part’s size, geometry, and the specific TPE grade. This choice directly impacts the final product quality by preventing defects like jetting and flow marks.

The gate is the doorway for molten TPE to enter the mold cavity, and its design is more critical for TPEs than for many rigid plastics. Because TPEs have high viscosity, the gate needs to be large enough to allow for an easy, uniform flow without generating excessive shear heat. Too much shear can degrade the material, leading to weak spots or discoloration in the final part. I remember a project involving a soft-touch TPE handle. We initially used a simple pin-point gate for a clean break, but the high injection pressure required was causing shear burn right at the gate. The part looked great everywhere else, but that one blemish made it unusable.

We had to rethink our approach. We switched to a tab gate located on a non-visible edge of the part. This allowed us to use a larger opening, reducing the injection pressure and eliminating the shear burn. It’s a perfect example of how the right gate strategy solves problems before they even happen. The goal is always to achieve a smooth, progressive fill from the thickest section of the part to the thinnest. This helps prevent sink marks and voids.

Here’s a breakdown of common gate types used for TPEs:

| Gate Type | Description | Pros | Cons |

|---|---|---|---|

| Tab Gate | A rectangular gate attached to the side of the part. | Easy to machine, low shear, good for filling larger parts. | Requires manual trimming, can leave a noticeable vestige. |

| Fan Gate | A wide gate that spreads the flow of material into the cavity. | Reduces stress, prevents jetting, ideal for flat, thin parts. | Can be difficult to degate, takes up space on the part. |

| Pin-Point Gate | A small, circular gate that often "snaps" off during ejection. | Automatic degating, good for multi-cavity molds. | Can cause high shear, not suitable for all TPE grades. |

| Tunnel Gate | A gate that feeds material into the part below the parting line. | Automatic degating, hides the gate mark on a non-cosmetic surface. | More complex to machine, can be difficult to remove. |

Choosing the right one depends entirely on your part geometry, the TPE grade you’re using, and your cosmetic requirements. Don’t be afraid to gate onto a thicker section, even if it seems counterintuitive. For TPEs, this helps pack the part properly and control shrinkage.

Why Is a Specialized Cooling System Crucial for TPE Molds?

Are you constantly fighting long cycle times and warped TPE parts? It can feel like you’re just waiting and waiting for the material to cool, only to pull out a part that’s distorted anyway. This inefficiency eats into your profits and delays shipments. What if your cooling system was perfectly tailored for TPE, ensuring fast, uniform cooling every single time and delivering dimensionally stable parts?

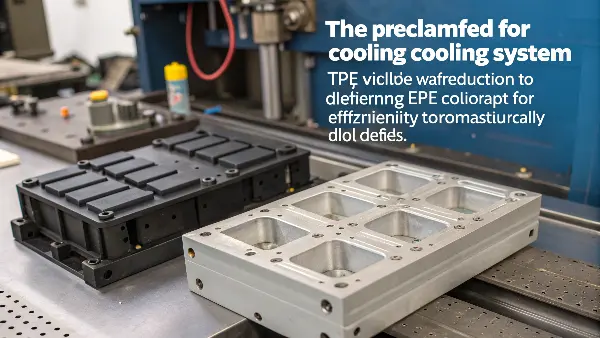

A specialized cooling system is vital for TPE molds because TPEs have poor thermal conductivity and retain heat much longer than rigid plastics. Efficient and uniform cooling is necessary to control shrinkage, prevent warpage, and significantly reduce cycle times. Cooling channels must be placed strategically close to the cavity surface, especially in thick sections, to ensure consistent heat removal and produce stable, high-quality TPE parts.

Think of TPE as a thermal insulator. Unlike plastics like polypropylene that transfer heat quickly, TPE holds onto it. If your mold cooling isn’t aggressive and even, you’ll get hot spots. These hot spots cause differential shrinkage—where one part of the component shrinks more than another—which is the primary cause of warpage. I learned this the hard way on an early project for an automotive client. We were molding a large, flat TPE gasket. The mold had a standard cooling layout, and the parts kept coming out twisted like a potato chip.

We spent days tweaking processing parameters with no luck. Finally, we pulled the mold and analyzed its cooling. The channels were too far from the cavity surface, and a few areas had no cooling at all. We re-machined the mold, adding extra cooling lines that closely followed the contour of the part, a technique now known as conformal cooling. The results were immediate. The cycle time dropped by 30%, and the parts came out perfectly flat. It was a powerful lesson: with TPEs, you can’t treat cooling as an afterthought. It has to be a core part of the design strategy.

Here are the key principles for effective TPE mold cooling:

Key Cooling Design Principles

- Proximity is Everything: Place cooling channels as close to the molding surface as possible, typically within 1.5 to 2 times the channel’s diameter. This minimizes the distance heat has to travel.

- Separate Circuits: Use separate cooling circuits for the core and cavity halves of the mold. The core often runs hotter, and having independent control allows you to balance the heat removal for uniform cooling.

- Target Thick Sections: Pay extra attention to thick-walled areas of the part. These sections hold the most heat and are the most prone to sink marks. Add dedicated cooling lines, like baffles or bubblers, to extract heat from these critical zones.

- Maximize Flow: Ensure your cooling channels have a large enough diameter and are free of sharp turns that could restrict water flow. High-volume, turbulent flow is much more effective at removing heat than slow, laminar flow.

By implementing these strategies, you move from passively cooling the mold to actively managing the thermal profile of the part itself. This control is what separates an average TPE molder from a great one.

What Ejection Strategies Work Best for Flexible TPE Parts?

You’ve successfully filled the part and cooled it perfectly, but now comes the final challenge: getting it out of the mold without damage. With rigid plastics, a simple push from an ejector pin usually does the trick. But with soft, flexible TPEs, those same pins can stretch, tear, or puncture the part, turning a good part into scrap right at the finish line. This is a common and incredibly frustrating problem for many manufacturers.

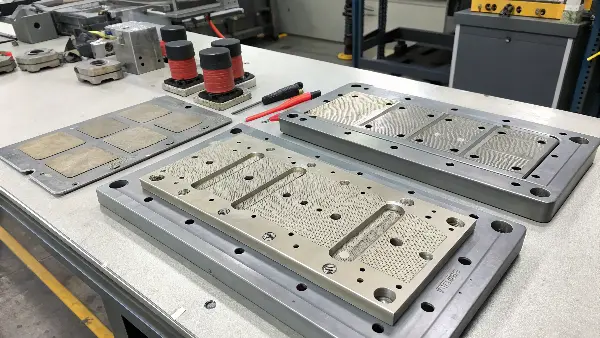

The best ejection strategies for flexible TPE parts involve maximizing surface area to distribute force evenly and prevent damage. Instead of small ejector pins, use large-area ejector pads, sleeves, or stripper plates. Air-assist features and applying a textured or polished surface finish to the mold can also help release the part, overcoming the material’s natural tendency to stick. The goal is a gentle, uniform push rather than a sharp, localized force.

TPE’s flexibility is its greatest strength in application, but its greatest challenge in molding. It doesn’t behave like a solid. When you push on it with a small pin, it’s like poking your finger into dough—it just deforms around the pin. If the material is also a bit sticky, which many TPE grades are, the pin can end up tearing right through the part. I’ve seen entire production runs scrapped because of poor ejection design. One customer came to us with a TPE boot that was getting damaged by ejector pins on every cycle. The part had a thin flange that was tearing.

Our solution was to redesign the ejection system completely. We replaced the individual pins with a custom stripper ring that matched the contour of the part’s flange. This stripper ring pushed on the entire edge of the part at once, distributing the force over a huge surface area. The part came off cleanly every time, with no marks or tears. It highlights a critical rule for TPEs: spread the load.

To build a robust ejection system for TPE, consider these tiered strategies:

Ejection Methods for TPE

-

Maximize Ejector Surface Area:

- Ejector Pins: If you must use pins, use as many as possible and make them as large in diameter as the part design allows. Place them on thick, non-cosmetic areas like ribs or bosses.

- Ejector Sleeves: These are excellent for pushing on round features, as they distribute force around the entire circumference.

- Stripper Plates/Rings: This is often the best solution. A plate or ring makes contact with the entire perimeter of the part, providing a smooth, uniform push that eliminates stress points.

-

Reduce Sticking:

- Surface Finish: A highly polished mold surface (SPI-A2 or better) can sometimes increase stiction due to a vacuum effect. A lightly textured surface (using bead blasting, for example) can actually help break the vacuum and make release easier.

- Draft Angles: Be generous with draft angles, typically 2-5 degrees or more. This helps the part separate from the core and cavity walls as the mold opens.

-

Incorporate Air-Assist:

- Air Poppets: Strategically placed air poppets can introduce a small blast of compressed air between the part and the mold surface just before ejection. This small pocket of air is often all that’s needed to break the seal and allow the part to release with minimal force.

A successful ejection strategy is a combination of mechanical force and clever design features that help the part release itself. By thinking beyond simple ejector pins, you can ensure that every TPE part you mold comes out of the tool as perfectly as it was designed.

Conclusion

Mastering mold design for TPE materials comes down to respecting the unique properties of the material. By focusing on three key areas—intelligent gate location to ensure clean filling, a robust cooling system for dimensional stability, and a gentle yet effective ejection strategy—you can overcome common molding challenges. These principles will help you reduce cycle times, minimize scrap, and produce high-quality, reliable TPE parts for your customers every time.