Are you a product designer trying to create the perfect plastic part, only to feel like the manufacturing tool itself is a mystery? This uncertainty can lead to design flaws, project delays, and expensive mistakes. But what if you could grasp the core concepts of injection molds, allowing you to anticipate problems before they happen? Let’s break down what an injection mold is and how it brings your brilliant designs into the real world.

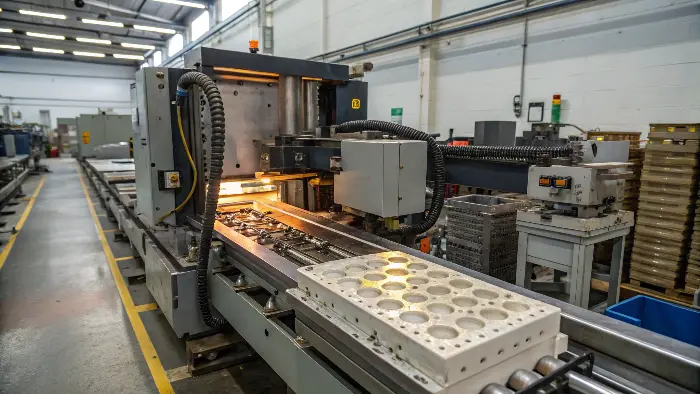

An injection mold is a custom-made tool, usually from steel, that functions like a highly precise, reusable 3D negative for shaping molten plastic. Molten plastic material is forced under high pressure into a hollow space within the mold, known as the cavity. After the plastic cools and hardens into the desired shape, the mold opens, and the finished part is ejected. This method is essential for mass-producing identical plastic parts with incredible speed and accuracy.

That’s the basic idea, and it’s a good starting point. But if you want to design parts that are not just functional but also optimized for manufacturing, you need to look closer. A true understanding goes beyond the simple definition. To truly master your craft, you need to explore the deeper meaning of the mold, the specific steps of the process it enables, and why this technology is so fundamental to modern industry. Let’s dive in.

What is the meaning of an injection mold?

You know that a mold makes parts, but do you really understand what it represents? It’s easy to dismiss it as just a heavy block of steel. This view can cause you to underestimate its complexity, where every single groove, pin, and channel serves a critical purpose. Ignoring these details can derail an entire project. So, let’s look beyond the surface. An injection mold is not just a tool; it’s the physical blueprint of your design, engineered to perfection.

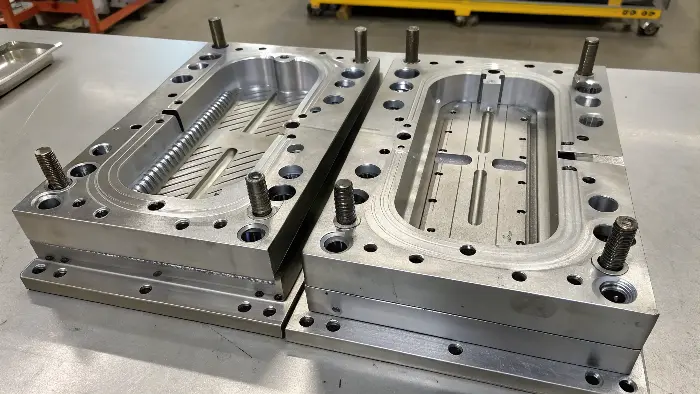

At its core, an injection mold is a highly engineered, hollow tool made from hardened steel like P20 or H13. Its primary function is to be the precise negative shape of the part you want to create. It is built in two main halves, the "A" side (cavity) and the "B" side (core). When these halves are closed together, they form a void—the mold cavity—into which molten plastic is injected. It is the heart of mass production for plastic components.

When I was just starting as an apprentice in a mold factory, I remember the first time I saw a complex mold taken apart for maintenance. I was completely amazed. It looked like an intricate three-dimensional puzzle made of polished steel. My mentor saw my expression and told me, "Every single piece you see, from the largest block to the smallest pin, has to work in perfect harmony. If one part is off by the width of a human hair, the entire batch of products could be ruined." That day, I learned that mold making is as much an art as it is a science. It’s about turning a digital design into a physical reality that can be replicated millions of times.

To help you understand this "puzzle," here are the basic components of a standard mold:

| Component | Function | Why It’s Important for a Designer |

|---|---|---|

| Cavity (A-Side) | Forms the external, cosmetic surface of the part. | This is the "show" side. Surface finish and texture are defined here. |

| Core (B-Side) | Forms the internal, functional features of the part. | This side often includes ribs, bosses, and other structural elements. |

| Runner System | A network of channels that guides molten plastic. | The runner design affects fill pressure, cycle time, and material waste. |

| Gate | The specific entry point where plastic enters the cavity. | Gate location is critical; it affects part appearance and structural integrity. |

| Ejector Pins | Pins that push the cooled part out of the mold. | Your design needs draft angles so these pins can push the part out cleanly. |

| Cooling Channels | Passageways for water to regulate the mold’s temperature. | Proper cooling is key to preventing part defects like warping and sink marks. |

Thinking about a mold in terms of these components helps you design parts that are not just possible to make, but easy to make well.

How does the injection molding process actually work?

You’ve finalized your part design, and the steel mold is ready. But what exactly happens between the moment the machine operator presses the ‘start’ button and when you’re holding a finished part? Many designers don’t have a clear picture of this cycle. This gap in knowledge can lead to designs that are difficult to mold efficiently, causing defects that send you right back to your CAD software. Let’s walk through the injection molding cycle step-by-step, because understanding this process is the key to creating manufacturable parts.

The injection molding process is a rapid, repeatable cycle with four main stages: clamping, injection, cooling, and ejection. First, the two halves of the mold are pressed together with immense force. Second, a precise amount of molten plastic is injected into the mold cavity. Third, the plastic cools and solidifies, taking the shape of the cavity. Finally, the mold opens, and the part is pushed out. This entire cycle can be as short as a few seconds.

I once had a client in my trading company who was facing a huge problem with warping parts. The factory kept blaming the plastic material, but the issue persisted. I flew to the facility to see for myself. After watching the process and inspecting the mold, I suspected the problem wasn’t the material at all. We found that the cooling channels inside the mold were poorly designed. One side of the part was cooling much faster than the other, causing it to warp as it solidified. A small modification to the mold’s internal water lines solved the problem and saved the entire project. That experience taught me a valuable lesson: the process is everything.

Here’s a deeper look at each stage:

1. Clamping

Before any plastic is injected, a powerful hydraulic system pushes the two halves of the mold together. This creates a tight seal and holds the mold closed against the immense pressure of the injection stage. The force required, known as clamping tonnage, is a key specification of an injection molding machine. If the clamp force is too low, the molten plastic can force the mold open slightly, creating a thin layer of excess material around the part called "flash."

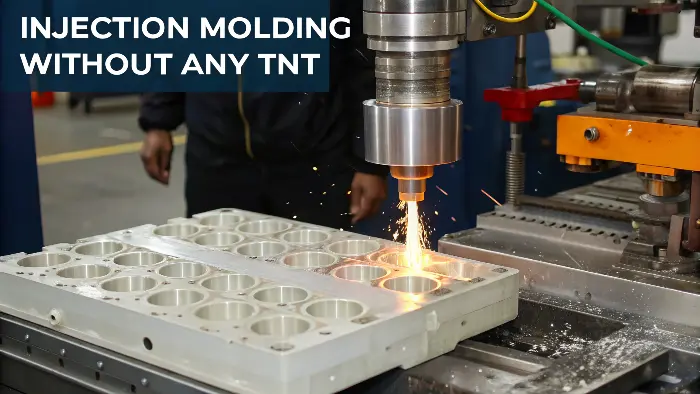

2. Injection

With the mold securely clamped, the injection phase begins. Plastic pellets are fed from a hopper into a heated barrel. A large rotating screw inside the barrel melts the pellets and pushes the molten plastic forward. When enough molten plastic has accumulated, the screw rams forward like a plunger, forcing a "shot" of material through the runner system, through the gate, and into the mold cavity. This happens very quickly and under extremely high pressure to ensure the cavity is filled completely.

3. Cooling

Once the cavity is filled, the cooling stage begins. This is often the longest part of the entire cycle. Water or another coolant circulates through channels built into both halves of the mold to draw heat away from the plastic. The plastic must cool down enough to solidify and hold its shape before the mold can be opened. The cooling time depends on the type of plastic, the thickness of the part’s walls, and the efficiency of the cooling system. As a designer, creating uniform wall thickness is the best thing you can do to promote even cooling and prevent defects.

4. Ejection

After the part has cooled sufficiently, the mold opens. The "B" side of the mold, which contains the core, moves away from the stationary "A" side. As it opens, a system of ejector pins located behind the core pushes forward, forcing the solidified part out of the mold. The part then falls into a collection bin, and the machine is ready to start the next cycle. This is why draft angles—slight tapers on the part’s vertical walls—are so important. Without them, the part would stick to the core, and the ejector pins could damage it during removal.

What is the significance of injection molding?

We now know what a mold is and the process it uses. But why has this specific technology been a cornerstone of manufacturing for so many decades? It’s easy to take it for granted. Without injection molding, the consumer electronics, medical devices, and automotive components we use every day would be incredibly expensive or simply impossible to produce at scale. Your job as a product designer would be fundamentally different and far more limited. Let’s explore why injection molding is so significant, because understanding its impact helps you leverage its power.

The true significance of injection molding is its unmatched ability to produce huge quantities of complex plastic parts with high precision, incredible speed, and a very low cost-per-part. This unique combination makes it the dominant method for mass production. It enables intricate designs, guarantees consistent quality from the first part to the millionth, and offers a vast choice of materials and colors. From a simple bottle cap to a complex car dashboard, injection molding is the invisible engine of modern manufacturing.

I once consulted for a startup launching a new kitchen gadget. They were planning to use 3D printing for their first production run to avoid the high upfront cost of a mold. I sat down with them and ran the numbers. The injection mold would cost them $50,000, but their per-part cost would be just $0.30. With 3D printing, their per-part cost was $8.00. I showed them that once they sold more than 6,500 units, the injection mold would not only pay for itself but become far more profitable. They took the leap, and they’ve now sold over a million gadgets. That story perfectly illustrates the economic power of injection molding.

Let’s break down its key advantages in a more structured way:

| Advantage | Explanation |

|---|---|

| Speed & Efficiency | Cycle times are measured in seconds. A single mold can produce millions of parts per year, making it ideal for high-volume production. |

| Low Cost Per Part | While the initial mold investment is high, the cost to produce each individual part is extremely low, especially at high volumes. |

| Design Complexity | Injection molding can create incredibly complex and intricate shapes, including features like living hinges, threads, and snap-fits, all in a single step. |

| High Repeatability | The process is highly automated and controlled, ensuring that every part produced is virtually identical to the last. This is critical for quality control. |

| Wide Material Choice | There is a massive library of thermoplastic polymers available, each with different properties for strength, flexibility, color, and temperature resistance. |

Of course, there are trade-offs. The primary one is the high initial cost and long lead time to create the mold. This makes injection molding unsuitable for very low-volume production or prototypes. Furthermore, once the steel mold is cut, making design changes is difficult and expensive. This is why it’s so important for you, the designer, to get the design right before the mold is made. For a product designer working on consumer electronics, the benefits are clear. You can design a complex phone case with integrated clips, screw bosses, and thin walls, and be confident that injection molding can produce millions of them perfectly. It’s the technology that makes mass-market products possible.

Conclusion

In the end, an injection mold is far more than a block of steel. It is a precision tool that defines the shape of your product, the heart of a process that brings it to life, and the key to making it affordable for the masses. Understanding what it is, how the cycle works, and why it’s so significant is the foundation for any designer working with plastic parts. This knowledge is the first step to mastering your craft and molding things right.