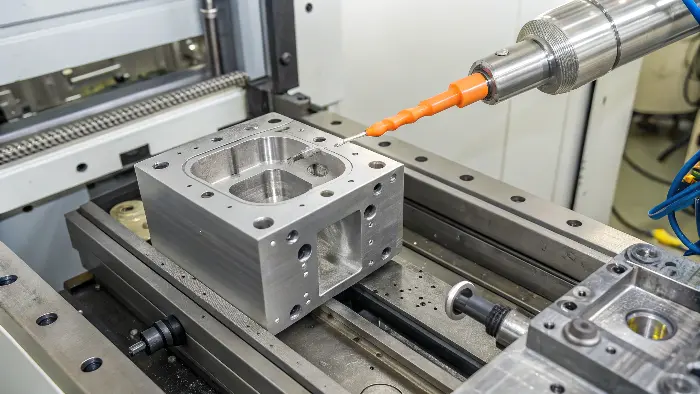

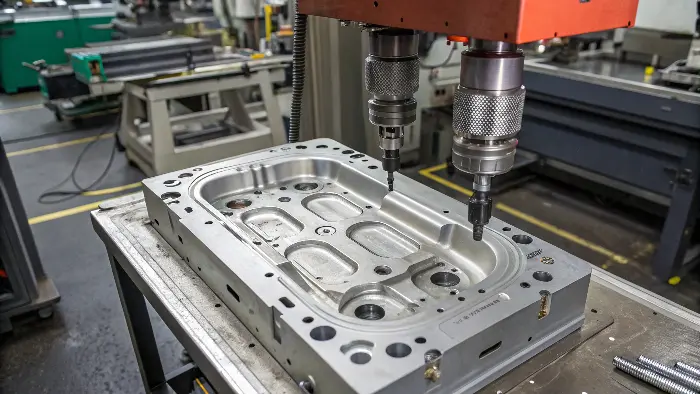

A mold is an empty metal block through which molten plastic is injected to take the shape of a definite shape. Even though they are not depicted in the figure below, in reality there are numerous holes drilled in the block to control temperature through the medium of hot water, oil or heaters.

Hot plastic is pumped into a mold via a sprue and flows into cavities via runners and gates. The mold is subsequently opened following the cooling process and the injection molding machine’s ejector rod forces the ejector plate of the mold to eject additional moldings.

An injection mold is a specifically made instrument which is basically a hollow block of metal that contains a accurately shaped hole within it. It is typically made out of tough steel (e.g. P20 or H13). During the production procedure, hot plastic in liquid stain is pressured in large quantities into this hole. The plastic is then left to cool and become solid, acquiring the specific shape of the cavity. The mold is opened, and the complete part of plastic is extruded. The cycle enables the production of similar parts in a swift and repeat fashion, including a bottle cap and a car dashboard.

That is the high level overview. But there is more to that to master this craft. I recall my initial days in a mold manufacturing plant where these huge blocks of steel can open and close through which the perfect parts are being spit at every few seconds. It was magic. However, there is nothing magic about it, it is engineering. The actual formula of success is know everything about the design and the functioning of these tools. So let us analyze that information.

What Is The Core Meaning Of An Injection Mold?

When you hear the phrase injection mold you can imagine an uncomplicated metal box. What can this tool really mean in the manufacturing world? It is easy to underestimate the complexity of the matter, when you think of it too simply. You may also lose the very important connection between the design of the mold and quality of the final product along with its strength and finish. Suppose we get at its real meaning. An injection mold is not just a mold, it is actually the core of mass-production of plastic parts.

The essence of an injection mold is the fact that, it is your final product inverted or negative. Just think of making a jelly dessert; the jelly has a shape because of the mold. The same is done by an injection mold except an injection mold does so by using high tech plastics at extreme conditions. It is a highly engineered piece of steel, which holds the exact inverse geometry of what it is you are interested in making. It is intended to mold molten plastic using immense pressure and heat and create a solid repeatable product.

Application of Injection Mold

Injection molding offers a very broad manufacturing venture of creating a wide variety of products about plastic products. Whether it is on wire spools or bottle caps and packaging materials or parts of car and toys and combs as also parts of movable instruments, the uses of the same are practically unlimited.

A variety of other common products which are in use can be manufactured through injection moulding such as those common plastic products such as bottle tops or remote control casings, syringe and so on. It is also applied commonly to manufacture big things like body panel of the vehicle.

Where there is a requirement to produce thousands or millions of identical parts using a mould then injection moulding is the primary method of manufacture.

It also is widely applied in the production of one-piece chairs, low size tables, storage boxes and gears and other machineries. Being the most widespread present-day method of forming plastic, the injection molding is particularly effective in case of large productions of the same objects.

This notion of the "negative space" I emphasize to ever-new designers who decide to do business with me. The "positive" is your device design. Its opposite is the mold. all the curves, ribs, bosses that you design on your part should be precisely 1 marked in the steel. That is why the mold is more than a piece of metal, it is the tangible example of how your online design was transferred into an object capable of producing millions of actual items. It is where your concept actually touches reality of production.

The Mold as a Blueprint in Steel

Think of the mold as a three-dimensional, functional blueprint. A paper blueprint only describes the part. The mold creates the part. This is why the choice of steel is so important. The material must be strong enough to withstand the immense pressure of injection, which can be thousands of PSI, and durable enough to last for hundreds of thousands or even millions of cycles without wearing down.

More Than Just a Cavity

A common mistake is to think the mold is just the cavity that shapes the part. In reality, it’s a complex machine with multiple integrated systems. The cavity and core (the two halves that form the part’s shape) are just one part of it. The mold also contains a network of channels for cooling fluid to flow through, a system of runners and gates to guide the plastic, and an ejector system to push the part out. Each system must work in perfect harmony.

Here’s a simple breakdown of common mold steels I’ve used over the years:

| Mold Steel Type | Key Characteristics | Typical Application |

|---|---|---|

| P20 | Pre-hardened, good polishability, easy to machine | Prototyping, low to medium volume production runs |

| H13 | High toughness, excellent heat resistance | High volume production, abrasive or corrosive plastics |

| S136 | High corrosion resistance, excellent polishability | Medical parts, optical lenses, transparent parts |

| NAK80 | Pre-hardened, high hardness, superb mirror finish | High-polish applications, precision components |

Choosing the right steel is a critical decision that balances cost, production volume, and the type of plastic being molded.

How Can We Explain Injection Molding Simply?

It may be challenging to describe the process of injection molding to the client or a new employee. There should be a simple and clear manner to explain it in a manner that is not lost in the technical terms. Explaining it in such a complicated manner may result in losing their interest or may get them confused that is what delays the project. I will simply explain it step by step in a way that everyone would understand.

The simplest description of injection molding is that is resembles a high-powered automatic hot glue gun. The first step is a melting of tiny plastic pellets to make a hot liquid. This liquid plastic is then forcefully squirted or shot into a closed metal mold among another thing. The plastic is cooled by circulation of water around the mold and as such, the solidification process is very fast. The mold is lastly opened and the new part of plastic pushed out. All this runs again, and again, in a few seconds or a little more, to produce thousands or millions of exactly the same parts.

The relevant assumption to be sequestered is the idea of a hot glue gun, because this device has the essential steps, melt, inject, cool, and eject. I recall how I attempted to talk of this with a manufacturing novice client. His face cleared when I applied this analogy. He got the idea at once. At that point, we would be able to discuss the details of his design much better, such as where he needed to locate the so-called nozzle (the gate) in his piece. This is an easy step between an old notion and a heavily industrialised procedure.

The Four Key Stages of the Injection Molding Cycle

While the analogy is useful, a professional like you needs to know the specific stages. The entire process is a finely tuned cycle. If any stage is off by even a fraction of a second, it can lead to defects. The cycle consists of four main stages that repeat seamlessly.

| Stage | Purpose | Critical Factors |

|---|---|---|

| 1. Clamping | The two halves of the mold are securely closed by the molding machine. | Clamping Force: Must be high enough to keep the mold shut against injection pressure. |

| 2. Injection | Molten plastic is forced from the injection unit into the mold cavity. | Injection Pressure & Speed: Controls how the part is filled. Too fast causes flash; too slow causes short shots. |

| 3. Cooling | The part solidifies inside the mold as heat is transferred to the mold. | Cooling Time: The longest part of the cycle. Determines cycle time and affects part shrinkage and warping. |

| 4. Ejection | The mold opens, and the ejector system pushes the solid part out. | Ejection Speed & Force: Must be controlled to avoid damaging or deforming the newly made part. |

Understanding these four stages is fundamental. As a designer, your choices directly impact each one. For example, a thick wall section in your design will dramatically increase the required cooling time, slowing down the entire production run and increasing the cost of every single part.

What Are The Key Components Of An Injection Mold?

You may know that a mold has a hole, but what about the rest of the parts that causes it to work? Learning all about the structure of a mold is essential in ensuring the designing of parts that can be produced in an efficient manner. By overlooking these additional elements, you will very easily design something that is hard to manufacture or one that causes typical defects in appearance such as sink marks, warping, or flash. Just to cut up a normal injection mold and see the key parts.

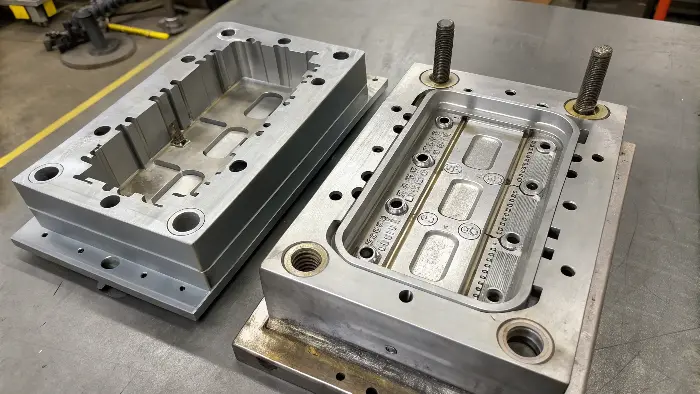

An injection mold is a complex assembly with several key systems. The two main halves are the A-side (or cavity side) and the B-side (or core side). Inside, you have the cavity and core, which come together to form the part’s shape. The sprue, runners, and gates create a pathway for the plastic to flow into the cavity. A cooling system of channels regulates the mold’s temperature. Finally, the ejector system, with its pins and plates, pushes the finished part out after it has cooled.

Once in a while, when I would start designing a mold on my first programs, I would simply take them apart and reassemble them. That was the easiest thing to teach myself how everything was to fit. It takes you quite a while to see the fact that a mold is not a single piece of steel but a complex of dozens of precision components collaborating. With this anatomy in mind, a designer will be able to foresee the manufacturing problems and incorporate elements that will eliminate or simplify the issues.

The Two Halves: A-Side and B-Side

Every standard mold is split into two halves.

- The A-Side (Cavity Half): This half usually forms the exterior of the part, often the "show" surface that the customer sees. It’s typically mounted on the stationary platen of the molding machine. The main sprue bushing, where plastic first enters the mold, is on this side.

- The B-Side (Core Half): This half is mounted on the moving platen. It usually forms the interior features of a part, like ribs, bosses, and other functional elements. The ejector system is housed within the B-side, as this is the half the part sticks to when the mold opens.

The Systems That Make It Work

Beyond the two halves, the mold is organized into several critical systems. As a designer, you need to consider how your part will interact with each one.

| System Name | Components | Function | Design Consideration |

|---|---|---|---|

| Feed System | Sprue, Runners, Gates | Delivers molten plastic from the machine nozzle to the cavity. | Gate location is critical. It affects filling, part appearance, and de-gating. |

| Shaping System | Cavity, Core, Slides, Lifters | Forms the actual shape of the plastic part, including undercuts. | Requires draft angles for easy release. Complex geometry may need slides or lifters. |

| Cooling System | Cooling Channels, Baffles, Bubblers | Removes heat from the plastic, allowing it to solidify. | Uniform cooling is essential to prevent warping and minimize cycle time. |

| Ejection System | Ejector Pins, Blades, Sleeves, Ejector Plates | Pushes the solidified part out of the B-side of the mold. | Ejector pins must be placed on strong, non-cosmetic areas to avoid marks. |

| Venting System | Vents (tiny gaps) | Allows air trapped in the cavity to escape as plastic flows in. | Poor venting can cause incomplete parts (short shots) or burn marks. |

Thinking about these systems while you design is the difference between a good part and a great, manufacturable part.

Why Is Injection Molding So Significant In Manufacturing?

In the modern world, where there are many options to process something, such as those linked to 3D printing and CNC machines, why is injection molding so strong? Unless you are aware of its untold benefits, you will tend to use an inefficient process or more costly procedure in your project thus a huge amount of money and time goes to waste. Now, we are going to consider the main reasons why injection molding plays such a crucial role in mass production nowadays.

The relevance of injection molding is that it provides unparalleled combination of speed, accuracy and low-cost high volume result. It has made it possible to make very complex and fine detail parts with unbelievable consistency with the millionth part being nearly the same as the first one. It is very versatile since the process works with a vast selection of plastic materials and also colors. The high production of almost any product that should be produced in large volumes, whether medical syringe or phone case, would often have no other possible production method than injection molding. It is used for a variety of reasons, including:

Flexibility:

the plastic injection mold design and the type of thermoplastic used in every component are a choice that the manufacturers have. The implication is that injection molding can create a wide range of components, such as components that are complex and intricately detailed.

Consistency:

when the process parameters are tightly controlled, injection molding can rapidly produce thousands of plastic components of consistent quality.

Cost-effectiveness:

After the mold (which is the most costly item) has been constructed, the cost per component to produce is fairly cheap, especially if produced on a large scale for bulk production.

Efficiency:

once the process has been established and tried, injection molding machines are capable of high volume production. Electric injection molding machines also render the process relatively energy efficient.

Quality:

Manufacturers who are seeking robust, tensile or highly detailed parts, the injection molding process can deliver them to a high quality time and again.

I used to have a client who was producing a small electronic enclosure by CNC machining. They were also producing only a few hundred per month, and the cost per part was very high. They were unaffordable as their demand rose in the thousands. We redone the injection molded part. It was expensive to setup the mold but cost of individual pieces went down by more than 90 percent. This one alteration rendered their product profitable and enabled their venture to expand in magnitude to a huge scope. That is the strength in injection molding.

The Economics of Scale

The biggest factor is the economics. Injection molding has a high initial cost because designing and building a precision steel mold is expensive. However, once that mold is made, the cost to produce each individual part is extremely low. This is the opposite of processes like 3D printing, where the first part is cheap but the 10,000th part costs the same.

Here’s a simplified look at the cost relationship:

| Manufacturing Method | Cost for 100 Parts | Cost for 10,000 Parts | Cost for 1,000,000 Parts |

|---|---|---|---|

| 3D Printing | Low | High | Very High |

| CNC Machining | Medium | High | Very High |

| Injection Molding | Very High (due to mold) | Medium | Very Low |

This table shows why injection molding is the go-to choice for mass production. The high upfront cost is spread out over many parts, making it incredibly efficient at scale.

Unmatched Versatility and Precision

Beyond cost, injection molding offers incredible design freedom.

- Material Choice: You can use hundreds of different types of thermoplastics, each with unique properties for strength, flexibility, temperature resistance, and color.

- Complexity: You can mold complex geometries, intricate textures, and thin-walled sections that would be difficult or impossible with other methods.

- Repeatability: The process produces parts with very tight tolerances, ensuring that every part is consistent. This is why companies like LEGO use injection molding; every brick has to fit together perfectly, every time.

From the dashboard in your car to the cap on your water bottle, injection molding is the hidden engine of the modern consumer world. Its ability to deliver quality, complexity, and consistency at scale is why it remains so significant.

Conclusion

Finally, an injection mold is not just block of steel. It is the reverse of your part, a complicated machine, that has many systems in it, and it is history to correct work in masses. It follows a straightforward cycle; it is done by clamping, injecting, cooling, and ejecting. This basis is the most significant and the initial stage of learning how to design mold and create successful plastic products. It is the information that makes a good idea into a million little details.