Do you have any concern about your plastic products fitting in close food safety standards? Making the wrong choice of mold steel may cause contamination, recall of the product and lose of your brand image. It is not only a compliance problem, it is a matter of consumer trust. One wrong move in the choice of the material may cost a lot and have a long-term effect. The first step towards quality and safety is to know why certain steels such as S136 are necessary.

S136 stainless steel is the best food-safe molding due to its unparalleled corrosion resistance, purity and the ability to polish exceptionally. Such properties ensure that the final plastic product does not transfer rust and contaminants to the end product and fulfills high health and safety requirements. Its longevity also ensures a long life of the mould, which ensures product quality remains high in millions of cycles, which are essential in high-volume food and medical grade production.

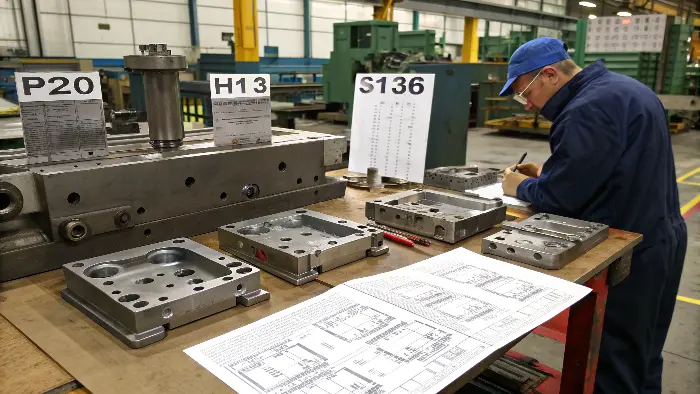

The correct selection of steel is one of the most important choices in mold making. It influences not only the quality of the end product, but also the life of the mold and your total production expenses. I have personally experienced how the appropriate material could complete or fail a project. So, we are going to plunge into the realm of mold steels to learn what makes them so significant and which one will be the best in your particular case.

What is the fundamental purpose of mold steel in manufacturing?

Ever wonder why so much is made of the kind of steel you use to cast a mold? It may sound like any hard metal would be sufficient to the task. However, the application of incorrect material can result in premature breakdown of the mould, inadequate finish on the surface of your parts, and expensive production delays. The selection of steel is no trifle. We are going to demanipulate the fundamental functions of mold steel during the manufacturing process.

Mold steel’s primary use is to create the cavity and core that shape molten plastic or metal into a final product. It must withstand immense pressure, high temperatures, and corrosive forces while accurately transferring intricate details. Its job is to be durable enough for millions of cycles, tough enough to resist wear and tear, and machinable enough to be crafted into complex geometries, forming the very heart of the injection molding process.

Steel selection is a starting point decision from which a manufacturing project’s success or failure hinges. It is not a lump of metal but a very specially engineered instrument for a tough, repetitive task. From my experience, where it is applied, its function can be summarized in three main areas.

Shaping the End Product

Mold steel’s most obvious purpose is to give the shape. The steel creates the negative, the mold cavity, in which the melted material fills. Its precision machinability and high-polish hold are a direct carryover to the finished appearance and dimension of the product. I recall a job for a company producing clear cosmetic jars. The high-polish on the steel was so critical that any minute imperfection was accentuated on the finished piece. We did have to use a high-polish steel and put additional time in on the final finish, but the end product was a clear piece appearing to be glass. This is where the quality of the steel is a direct carryover to the quality of the product.

Enduring the Manufacturing Gauntlet

Injection molding is a tough environment. The steel has to handle clamping forces in the thousands of tons, rapid heating and cooling cycles, and the abrasive or corrosive nature of some plastics. This is where properties like hardness, toughness, and corrosion resistance come into play. A steel that can’t take the heat will literally lose its shape over time, and a steel that rusts will contaminate the parts.

Ensuring Economic Viability

A mold is a long-term investment. The correct steel keeps the mold capable of producing millions of parts without having to be repaired or replaced every time it is damaged. This survival or mold life is one of the most important aspects of cost calculation per part. Having cheaper steel can save money in the short term, but in the long term, it will prove much more expensive in downtime, maintenanc,e and rework.

| Property | Why It’s Important in a Mold | Consequence of Poor Choice |

|---|---|---|

| Hardness | Resists wear, scratches, and indentation from plastic flow. | Poor part quality, short mold life. |

| Toughness | Prevents cracking under high pressure and impact. | Catastrophic mold failure, danger. |

| Corrosion Resistance | Protects against rust from moisture and certain plastics. | Part contamination, surface defects. |

| Polishability | Achieves a smooth or textured surface on the final part. | Poor aesthetics, functional issues. |

| Machinability | Allows for the creation of complex and precise mold shapes. | High manufacturing cost, design limits. |

Steel Applications S136

S136 is a stainless tool steel of high quality admired for corrosion resistance, hardness, and excellent polishability. It is extremely popular in tooling and mold applications, especially where cleanliness and surface finish are a factor.

1. Plastic Injection Molds

Usually applied on clear materials such as PMMA, PC, and PS.

Ideal for use in wet locations or on caustic plastics such as PVC.

Provides long life with minimum possibility of contamination and rust.

2. Extrusion Dies and Blow Molding Dies

Utilized in blow bottles and container molds for the reason that it is resistant to water corrosion from cooling and condensation.

Maintains smooth faces on extrusion tooling for consistent product quality.

3. Transparent and Optical Plastic Components

Ideal for lenses where mirror finishes are desired such as in light guides, covers, etc.

Prevents surface defects from occurring, which might impact transparency and optical performance.

4. Tooling for Medical and Food-Grade

Extensively used in medical device molds, pharmaceutical packaging, food packaging.

Offers hygiene benefits in that it does not corrode and can accept a cleaning or sterilization operation.

5. Corrosive or Flame-Retardant Plastics

Ideal for compounding plastics with flame retarders or fillers resulting in acidic byproducts.

Lowered maintenance expense and minimizes early tool wear.

6. Precision Applications and High-Gloss Applications

Good material for cosmetic packaging molds, car light covers, and optical discs.

Guarantees wear resistance and high surface polishability.

S136 stainless steel is overwhelmingly utilized in clear tools and tooling where luster, corrosion protection, and wear resistance are a necessity—therefore perfect for clear, medical, food-safe, and cosmetic products

So, which steel is actually the best for making a mold?

Among all the kinds of mold steel in the market, how do you get the right one? The technical data sheets may be confusing, jargon and figures. Choosing the incorrect one may include a mold that will wear out too soon, create defective parts, or just cost too much to do the job. The fact is that there is no one best steel. The option of the choice solely depends on your own project needs.

The "best" steel for molding depends on your application’s specific needs, including the plastic material, required production volume, and desired part finish. For general-purpose, low-volume molds, pre-hardened steels like P20 are cost-effective. For high-volume, abrasive materials, you need a high-hardness steel like H13. For high-polish and corrosive environments, especially for clear parts or PVC, a stainless steel like S136 is superior. The key is to match the steel’s properties to the project’s demands.

The selection of steel is a juggling act regarding cost and performance and longevity. You would not take a race car engine to your daily commute and the same case applies here. I tend to take clients through this choice by posing three easy questions: What are you making? How many do you need? And what must it appear to be like? These questions tend to lead us to one or two of the common families of steel.

Workhorse: P20 Steel

Steel alloy

P20 is the universal for a lot of jobs. It’s pre-hardened, so you save time and money on heat treating. It’s perfect for prototypes and small production jobs of non-corrosive plastics such as ABS or polypropylene. It’s consistent, easy to machine, and inexpensive. It won’t produce a mirror finish, though, and it’s not good for corrosives or very abrasive plastics. It’s the family sedan of the mold steels.

H13 Steel – A Jack-of-all-trades in

If you need something for high-volume use or are working in an abrasive material like glass-filled nylon, H13 is a good choice. It’s a tool steel and has to be heat-treated for optimum properties, but it ends up being a very hard material. It can handle millions of cycles with very little wear. You pay for it in the sense that it’s more than P20 to machine and to work with, though, due to the added heat-treat step.

Specialist: S136 Stainless Steel

This brings us back to our star player. S136 is a stainless steel, meaning its primary advantage is corrosion resistance. This makes it essential for molding PVC, which releases corrosive gases, or for medical and food-grade products where rust is unacceptable. It also polishes to a beautiful mirror finish, perfect for lenses, light pipes, and clear casings. It’s the premium choice for applications where purity and appearance are non-negotiable.

| Steel Type | Best For | Key Advantages | Key Disadvantages |

|---|---|---|---|

| P20 | Prototypes, medium-volume, non-corrosive plastics. | Cost-effective, good machinability, no heat treat. | Moderate hardness, poor corrosion resistance. |

| H13 | High-volume, abrasive plastics (e.g., glass-filled). | High hardness, excellent wear resistance. | Requires heat treatment, higher cost. |

| S136 | Food/medical grade, clear parts, corrosive plastics. | Excellent corrosion resistance, mirror polish. | Higher material cost, can be tougher to machine. |

What is the difference between 718H and S136?

The primary distinction between 718H and S136 steel is properties and application. 718H is a pre-hardened mold steel that has a hardness between 33 and 40 HRC. It has good toughness and machinability and is applicable in general-purpose molds in the automotive parts, household, and industrial products. The downside is however that it only has moderate corrosion resistance, and thus may corrode in humid conditions or when it is involved in processing corrosive plastics like PVC. Although 718H has the capability to produce a good surface finish, it does not work best in those applications that demand a mirror-like finish. It is largely used because it is cost-effective, and it is mostly acceptable when it comes to large molds with no significant concern on the surface quality or corrosion resistance.

S136, however, is a stainless mold steel with more chromium that is highly resistant to corrosion. Hardening can be taken to approximately 50 to 52 HRC; it is also appreciated due to high polishability. This renders it the choice of moulds to be used in manufacturing transparent plastics, medical equipment, cosmetic containers, and food-grade items, where hygiene, as well as optical clarity, is mandatory.

Compared to 718H, S136 is highly applicable in wet environments or in surfaces where the cooling water comes into contact with the mold. S136 is higher priced, however, it needs minimal maintenance and has a longer service life in rigorous applications.

718H is used in general-purpose, cost effective molds and S136 in high-end molds requiring corrosion resistance, strength and a smooth, clean surface finish.

Is steel always the best metal for making molds?

We’ve talked a lot about steel, but is it the only option for making molds? You might hear about other metals being used and wonder if you’re missing out. Sticking only to steel when another material could offer faster cycle times or better heat transfer could be costing you time and money on every single part you produce. Let’s explore the world beyond steel and see when other metals might be a better choice.

**Although steel is the most popular metal used in making molds because of its durability, it does not necessarily make the best one. Aluminum is very suitable for use in prototyping and low-volume production. It is cheaper, lighter, and far easier to machine. It also has better thermal conductivity, which can greatly minimise the time spent in a cycle. Beryllium-copper alloys are applied to certain inserts that require very high heat transfer. The optimal metal really lies in the lifecycle of the project and the project’s needs.

A non-steel thinking can provide new avenues of efficiency. I was once in a project where I was expected to meet a very tight deadline for a trade show. We wanted hundreds of parts in a hurry. We used a 7075 aluminum mold as opposed to a conventional steel mold (P20). Molded and produced in less than half the time compared with steel, our customer was able to release its product on schedule.

The Case for Aluminum Molds

Speed is the greatest benefit of aluminum. It is far lighter than steel, and hence machines extremely fast. It has a thermal conduction that is approximately five times higher than that of steel, i.e., it warms and cools more quickly. This enables the reduction of injection cycle times, which can be an enormous saving in production cost. Nevertheless, it is not hard enough to be used with large volume production runs or hard materials. Neither is the sprinter, the marathon runner, but prototypes or bridge tooling.

The Role of Copper Alloys

Beryllium-copper (BeCu) is a specialty material. It has even better thermal conductivity than aluminum. You won’t see a full mold made of it due to its high cost and low hardness. Instead, it’s often used for small inserts in steel molds in areas that are difficult to cool, like thin ribs or deep cores. By quickly drawing heat away from these hot spots, BeCu inserts prevent defects like sink marks and speed up the overall cycle.

Why Steel Still Dominates

Despite such substitutes, though, steel is still the king for a reason: durability. To achieve any significant mass production, you require a system for tooling that can survive half a million or a million or more shots. Steel only offers the hardness and ruggedness to withstand such mistreatment. Copper and aluminum alloys do have their niches, of course, but for any high-volume manufacturing activity where durability is a factor, steel is the most practical and cheapest solution.

| Metal | Primary Advantage | Best Use Case | Main Limitation |

|---|---|---|---|

| Steel | Durability & Hardness | High-volume mass production | Slower cycle times |

| Aluminum | Machining Speed & Thermal Conductivity | Prototyping, low-volume runs | Low wear resistance |

| Beryllium-Copper | Superior Thermal Conductivity | Inserts for cooling hot spots | High cost, soft |

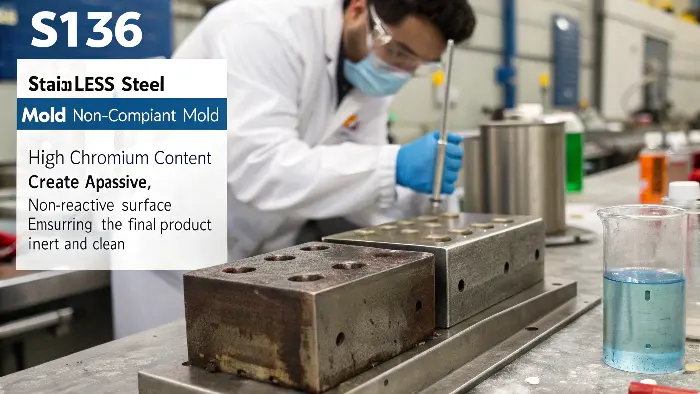

What makes a mold steel "safe," especially for food and medical products?

With products that come into touch with food or are used in a medical environment, you cannot afford to be good enough. The security of the end-user is of first importance. The application of a non-conforming mold steel may bring rust or other harmful components to the end product, resulting to certification failures, product recalls and possibly health hazards. Knowing what exactly makes a steel safe is very important to anyone in this industry.

A "safe" steel for molding, particularly for food-contact and medical applications, is one with high corrosion resistance and high purity. This means it won’t rust or leach metallic elements into the plastic part during the molding process. Stainless steels like S136 are considered safe because their high chromium content creates a passive, non-reactive surface. This ensures the final product is inert, clean, and complies with strict regulatory standards like those from the FDA

The idea of safety in molding is reduced to just one word, that of stability. You require a substance that does not melt or interact in severe environment of the molding procedure. Molds grown on ordinary steel have been observed to produce microscopic rust points in only a few weeks in a damp factory. Although these spots are not visible to the naked eye, they can infect all manufactured parts resulting in a significant contamination issue that can be catastrophic to a food or medical brand.

The Enemy: Corrosion

Corrosion, or rust, is the oxidation of iron. It happens when steel is exposed to oxygen and moisture. Certain plastics, like PVC, also release acidic gases during molding that aggressively attack the steel. This rust can flake off and embed itself in the plastic parts. For a food container or a syringe, this is completely unacceptable. It’s a direct path to contamination and product failure.

The Shield: High Chromium Content

This is where S136 shines. S136 is a stainless steel, which means it has a high percentage of chromium (typically 13% or more). The chromium reacts with oxygen in the air to form a very thin, invisible, and incredibly tough layer of chromium oxide on the surface of the steel. This "passive layer" acts as a shield, protecting the iron underneath from corroding. If the surface gets scratched, the layer instantly reforms, making it self-healing. This is the core reason S136 is so resistant to rust and chemical attack.

Beyond Rust: Purity and Polish

Safety isn’t just about rust. S136 is also produced using special refining processes (like Electro-Slag Remelting or ESR). This process remelts the steel to remove impurities like sulfur and other non-metallic inclusions. This results in a very clean, pure steel. This purity, combined with its ability to be polished to a mirror finish, means there are no microscopic pits or crevices where bacteria or residue can hide. This is absolutely critical for medical devices and food containers where cleanliness is paramount.

Conclusion

Mold material selection is a key decision affecting quality, profitability, and safety. While P20 and H13 steels are great for much industry use, and aluminum provides rapidity for proto-tooling, they are not superior in safety matters. For food-grade and medical-grade manufacturing, superior corrosion resistance, high purity, and polishability favor S136 stainless steel as the clear winner, guaranteeing your products to be safe and your company to be protected.