How Did We Solve Complex TPU Over-Molding for an Automotive Client?

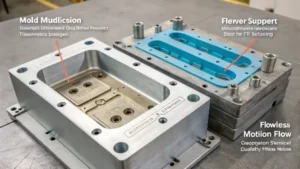

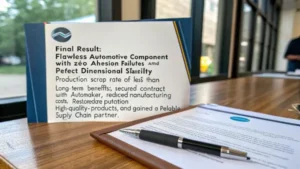

Struggling with complex over-molding projects can be a nightmare. You face high scrap rates, poor adhesion, and endless delays, which hurt your bottom line and reputation. What if you could turn these challenging projects into a success story? Our team at CKMOLD faced a similar challenge with a critical automotive