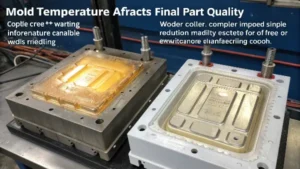

How Do Advanced Mold Temperature in Injection Molding Controls Revolutionize?

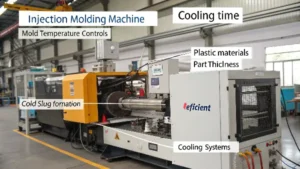

Do inconsistent quality of plastic parts, frustratingly long cycle times, and material waste eating into your profitability sound all too familiar? These common injection molding problems can stall your production and damage your hard-won reputation. It seems like you’re always fighting the machine to get the results that you need.