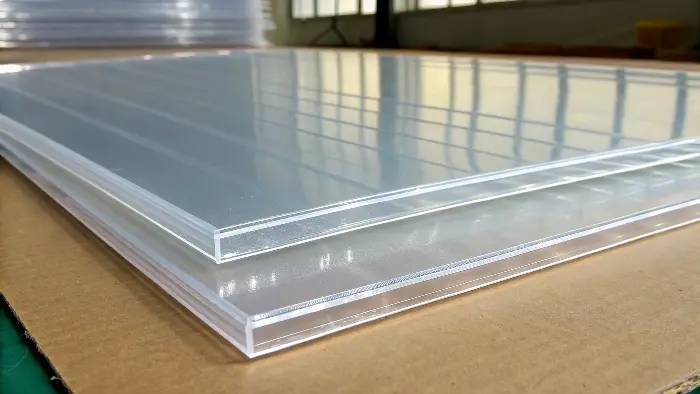

The material of your parts is hard to find, and you need it to be ridiculously strong and exceptionally clear at the same time? It can be exasperating when the condition is that materials of your strength needs to be opaque, or there is no material at all yet at least it can be clear material, but unfortunately not durable. This creates the tendency to tamper with the design or performance. An effective solution is the PC plastic molding, which supplies outstanding durability and uncompromising transparency in challenging usages.

PC plastic molding, through polycarbonate injection molding, is a production process where molten PC plastic is pressured into a mold cavity. The plastic cools and hardens, duplicating the shape of the mold with precision. The process is the preferred method for manufacturing highly strong, impact-resistant, heat-resistant, and optically clear parts for the automotive, electronics, medical device, and consumer appliance markets. It supports high-volume production of complex and precise parts with high repeatability.

You now have a simple understanding of what PC plastic moulding is but you are likely to have a lot more questions. It is a flexible procedure, however in order to effectively apply it, you have to know the material joining which itself- ex. what it is, what are its limitations, and what it is compared to other common plastics. These are the details that you need to have right to end up with a successful project. It is time to equip ourselves with more information on the world of polycarbonate to enable you make the most appropriate decisions in your designs.

What does PC plastic stand for?

You keep seeing the acronym "PC" every time in specs and technical talk. But not entirely sure what it represents or what it entails can be somewhat puzzling in your profession. This doubt can be a minus in the important design meeting. Let’s get this straight so you can have the knowledge to talk about this potent substance with confidence.

PC stands for Polycarbonate. It’s a performance thermoplastic polymer. The name is a pretty good hint at its chemistry: "poly" means many, and "carbonate" means the carbonate groups in its molecular backbone. This specific chemical structure is the source of its most famous properties: incredible impact strength, stiffness, and optical clarity. It’s a material engineered from the molecules up to be tough and transparent.

When I first got into this business I would see "PC" all of over drawings. I figured it was a strong, transparent plastic, but I had no idea "why" until I looked deeper into its composition. Realizing its a "polycarbonate" makes you understand how it behaves.

The Power in the Name: Thermoplastic

PC is a thermoplast. It is an important fact to any one in molding. What it means is that you are able to heat the product to a point of liquidity followed by molding and then cooling into a solid again. It is even possible to regrind scraps and uses the material again albeit personally, I will always insist that when it is a critical application then it should be fresh material. The reason as to why this property makes it so amenable to injection molding, which is a technique that is based on the melting and hardening of plastic a number of times.

Key Properties Derived from its Structure

The carbonate groups that link up the long chains of the polymer to form PC are what make it possess the unique set of features. My favorite project was to create a protective package of an industrial scanner. It was to be "virtually durable" said the client and he wanted to be able to see the indicator lights lit up inside. Already the preferred choice was PC. A two-meter drop on the concrete floor could be undertaken without any crack on the final parts. That was a lesson that made me realize the relationship between the name of the material and its performance in real-life.

Here’s a quick comparison of how PC stacks up against other common thermoplastics:

| Property | Polycarbonate (PC) | Acrylonitrile Butadiene Styrene (ABS) | Polypropylene (PP) |

|---|---|---|---|

| Impact Strength | Excellent (Virtually unbreakable) | Good (Tough but can crack) | Moderate (Flexible but lower impact) |

| Clarity | Excellent (Water-clear) | Opaque | Translucent to Opaque |

| Heat Resistance | High (up to 135°C / 275°F) | Moderate (up to 80°C / 176°F) | Moderate (up to 100°C / 212°F) |

| Stiffness | High | High | Medium |

Understanding that PC stands for Polycarbonate is more than just trivia; it’s the key to understanding why it’s one of the most reliable engineering plastics available for tough jobs.

Polycarbonate Advantages, and Applications

Fillers and additives may cause the typical values to go up or down but the general strength of polycarbonate cannot be changed. Five of them are particularly important as are seen in their applications.

Temperature strength and high resistance:

Polycarbonate is a very strong and durable plastic that is able to survive high impacts and withstand high temperatures. Examples of application would be automotive tail lights housings and LED lighting fittings.

Flexibility:

Surfaces with complicated shapes and designs can also be designed using the polycarbonate injection molding. One example is the enclosure of devices and equipment, e.g. scientific tools and medical robots.

Low cost:

Another aspect of the polycarbonate injection moulding process is that it is cost-effective and helps produce high-volume parts. High-volume PC component applications include brackets and medical tubing.

Optical transparency:

Polycarbonate is highly transparent with good optical clarity, which makes it suitable where there is a need of transparent or see-through components. Examples are eyeglass lenses, hard hat visors, and safety goggles.

Lightweight:

Polycarbonate is a very light weight plastic that can make a product much lighter at the end of the day. That applies to the automotive and aerospace industries, as well as handheld consumer products.

What are the disadvantages of PC plastic?

Polycarbonate is a wonder material, solving problems of strength and clarity at the same time. But if you buy it for a project without understanding its shortcomings, you may be inviting disaster. Parts will catastrophically crack, yellow, or scratch, leading you to have to recall them at a huge cost and ruin your reputation. It is equally important to understand the weaknesses of PC as it is to understand its strengths.

Although PC plastic has its advantages, it has some significant disadvantages. It is prone to scratching unless a hard protective surface is applied to it. It also stress-cracks upon exposure to some chemicals, primarily solvents and alkaline cleaners. It also yellows and becomes brittle with time when exposed to UV light from the sun. Finally, it requires high processing temperatures, hence increased energy consumption during production.

Anything and everything comes with trade-offs and PC is not any different. I got the hard way on one of my first ventures, an outdoor enclosure. We did not use any UV- stabilized grade and in a year the customer had complained that the clear covers had yellowed and were hazy. It came at a high cost of learning to be sensitive to the limitations of the material.

Susceptibility to Scratches and Chemicals

PC is a relatively soft material on the surface, making it easy to scratch. For applications like lenses or display covers, a hard-coating treatment is almost always necessary to maintain clarity. More importantly, PC is vulnerable to a phenomenon called environmental stress cracking (ESC). Certain chemicals, like acetone, gasoline, and some cleaning agents, can attack the polymer chains, causing microscopic cracks that lead to catastrophic failure, especially if the part is under stress. You must always check the chemical compatibility for your part’s intended environment.

Processing and Environmental Concerns

It is harder to shape PC compared to some other plastics.

- Significance of Drying: PC is hygroscopic, i.e., it absorbs moisture from the environment. If you try to shape it without drying it in advance (typically 4 hours at 120°C), the water will evaporate at processing temperatures and create splay marks and structurally weaken the part.

- High Temperatures: It has a high melting point, which requires process temperatures between 280-320°C (535-610°F). It is heavier-duty equipment and more energy intensive than polypropylene materials.

- BPA Issues: Most standard PC is made with Bisphenol A (BPA). While entirely safe for the overwhelming majority of industrial uses, it has proven to be a problem with food-contact and medical product uses. Thankfully, most "BPA-free" PC grades are now offered by suppliers to address this.

UV Degradation

| Disadvantage | Common Solution |

|---|---|

| Prone to Scratching | Apply a hard-coating post-molding. |

| Chemical Sensitivity | Check compatibility charts; choose a resistant grade. |

| Requires Drying | Pre-dry pellets thoroughly before molding. |

| UV Degradation | Use a UV-stabilized grade for outdoor applications. |

| BPA Content | Specify BPA-free grades for food/medical use. |

What is the difference between PVC and PC plastic?

In plastics, you will come across the acronyms PC and PVC. They sound alike, and if you are not working with them on a daily basis, you will easily confuse them. Replacing one with the other when you actually need the other can be disastrous. Having the wrong material will result in a product that will break, melt, or decay in its application, wasting time and money.

The primary distinction is that PC (Polycarbonate) is a structural plastic that is greatly valued for its great impact strength and clarity, while PVC (Polyvinyl Chloride) is a low-cost commodity plastic and extremely versatile. PC is used in such applications as bulletproof glass and goggles. PVC is much more ductile and used in pipes, electrical insulation, and inflatable items. They have vastly different uses and are not interchangeable.

I have clients who once requested whether I could produce a transparent machine guard to cut on costs using PVC. I needed to tell him that although PVC is a low cost material, a flying debris off the machine would probably break the material. We required the high impact withstanding quality of PC to keep the worker safe. Injury Avoidance was a good way to get even with the increased material cost. It is an ideal case when such knowledge about the difference can be called critical.

A Head-to-Head Comparison

Let’s break down the key differences in a more structured way. Thinking about these properties will help you choose the right material every time.

| Property | Polycarbonate (PC) | Polyvinyl Chloride (PVC) |

|---|---|---|

| Full Name | Polycarbonate | Polyvinyl Chloride |

| Impact Strength | Extremely High (250x stronger than glass) | Good, but can be brittle (especially rigid PVC) |

| Clarity | Excellent, optically clear | Can be clear, but often not as high-quality |

| Heat Resistance | High (up to 135°C / 275°F) | Low (around 60-80°C / 140-176°F) |

| Flexibility | Rigid and stiff | Can be rigid or very flexible (with plasticizers) |

| Chemical Resistance | Poor against solvents and alkalis | Excellent against acids, salts, and bases |

| Cost | Higher | Lower |

| Common Uses | Safety glasses, electronic housings, CDs, riot shields | Pipes, window frames, flooring, electrical cables |

| Recycling Code | #7 (Other) | #3 |

When to Choose One Over the Other

The choice is usually clear once you define your project’s needs.

- Choose PC when: Your top priority is impact strength, high clarity, and good performance at elevated temperatures. Think of it as the material for tough, protective applications where failure is not an option.

- Choose PVC when: Your main drivers are low cost, chemical resistance, and flexibility (or rigidity for applications like pipes). It’s a fantastic general-purpose material, especially where high impact strength and heat resistance are not required.

Never think of these materials as competitors. They are tools for different jobs. Using this table and thinking about your primary requirements will guide you to the correct choice every time.

Plastic Similar to Polycarbonate

There are a number of materials that are comparable to polycarbonate in relying on whether or not transparency or impact resistance is needed.

Acrylic (PMMA): Similar to PC, acrylic is clear and possesses good optical clarity. Acrylic is light in weight and provides resistance to UV. Acrylic is not as resistant to impact as PC, but it can be used as a good substitute for applications where high impact resistance is unnecessary, like signs, aquariums, and display cases.

Polyethylene (HDPE or LDPE): Polyethylene is a light and impact-resistant plastic. It is used in applications where flexibility and resistance to chemicals are more desirable than clarity, for example, bottles, pipes, and liners.

PETG (Polyethylene Terephthalate Glycol): PETG is clear in appearance, impact-resistant, and is easy to thermoform. It is commonly employed as an alternative to PC when there are fears regarding the possible release of bisphenol A (BPA).

What are the 5 types of plastic molding?

You’re familiar with injection molding for PC, but that’s just one method in a huge manufacturing landscape. Believing it’s the only option can be limiting. You might be designing a part that is better suited for a different, more cost-effective process, but you wouldn’t know it. Expanding your knowledge beyond one technique opens up new design possibilities and can save your company significant money.

The five main types of plastic molding are Injection Molding, Blow Molding, Extrusion Molding, Compression Molding, and Rotational Molding. Each process is designed for creating different types of plastic parts. For example, injection molding makes solid, complex parts like phone cases, while blow molding creates hollow items like bottles. Understanding the basics of each helps you match your product design to the most efficient manufacturing method.

As a designer, knowing these five methods is like having a full toolbox instead of just a hammer. You can create better products because you can design them with the best manufacturing process in mind from the very beginning. Let’s quickly go over each one so you can see the possibilities.

A Breakdown of the Core Methods

Each molding process has its own strengths and is suited for specific product geometries and production volumes.

1. Injection Molding

This is the process we’ve been discussing for PC. It involves injecting molten plastic into a closed mold. It’s the king of high-volume, high-precision production for solid parts.

- Process: Melt plastic, inject under high pressure, cool, eject part.

- Best for: Complex, detailed parts like gears, enclosures, LEGOs, and automotive dashboards.

- Key Advantage: High speed and low cost per part at high volumes.

2. Blow Molding

If you need a hollow part, this is your process. It starts with a hollow tube of hot plastic, called a parison, which is then inflated with air inside a mold.

- Process: Create a parison, clamp a mold around it, inflate with air.

- Best for: Bottles, fuel tanks, and any other hollow container.

- Key Advantage: Perfect for producing hollow objects quickly and cheaply.

3. Extrusion Molding

This process is for creating long, continuous parts with a consistent cross-section. Molten plastic is pushed through a shaped die.

- Process: Push molten plastic through a die.

- Best for: Pipes, tubing, window frames, straws, and plastic film.

- Key Advantage: Efficiently creates linear, continuous products.

4. Compression Molding

This method is one of the originals. A pre-measured amount of plastic (a "charge") is placed in the bottom half of a heated mold. The top half is then closed, and pressure is applied to force the material to fill the cavity.

- Process: Place plastic charge in mold, close mold, apply heat and pressure.

- Best for: Large, flat, or gently curved parts, often with reinforcing fibers, like electrical components and automotive panels.

- Key Advantage: Good for very large parts and high-strength thermoset materials.

5. Rotational Molding (Rotomolding)

This method is for making large, hollow, and complex items. Plastic powder is loaded into a mold, which is then heated and rotated on two axes. The powder melts and coats the inside of the mold.

- Process: Load powder, heat mold, rotate on two axes, cool, demold.

- Best for: Kayaks, large water tanks, playground slides, and other large, stress-free hollow parts.

- Key Advantage: Low-pressure process creates very strong, uniform-walled hollow parts with minimal residual stress.

Conclusion

In short, PC plastic molding is a top-tier process for creating parts that need to be strong, clear, and heat-resistant. We’ve covered what PC stands for, its key disadvantages, how it differs from PVC, and where it fits among the five main molding methods. Armed with this knowledge, you are now better equipped to select the right materials and processes, ensuring your designs are optimized for both performance and manufacturing success.