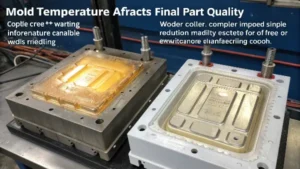

Are Your Injection Molds Vented Correctly for Different Plastics?

Do you have a problem of injection molding such as burn, short shots, or weak weld lines? It could be the machine or the material but the actual offender is usually lurking in the shadow. The problems result in delays during production and wastage of materials which are going to