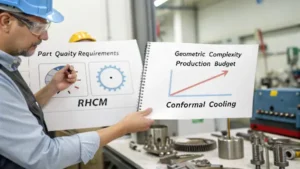

How Do You Translate Customer Requirements into Engineering Specifications for Plastic Parts?

The secret is to learn how to translate your needs into precise engineering specifications. If you have a great idea for a plastic part but your manufacturing partner keeps asking technical questions you can’t answer, this communication gap will cause delays, misunderstandings, and prototypes that don’t match your vision. Translating