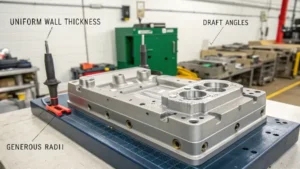

A Comprehensive Guide to Design for Manufacturing(DFM) in Plastic Part Design?

Have you ever designed a fantastic plastic part only to discover that it would be impossible to manufacture? This disconnect between design and reality can result in costly mold modifications, annoying hold-ups, and a subpar finished product. You invest a lot of time and money in a project, only to