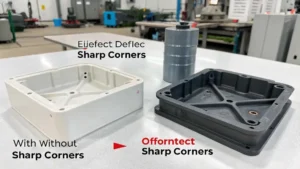

How Did We Eliminate Persistent Scratches in a Deep-Cavity Electronics Housing?

Are you struggling with a high scrap rate from scratches on your plastic parts? It feels frustrating when you’ve invested in a new mold, only to see profits disappear with every rejected unit. You know there’s a solution, but your current supplier can’t seem to find it, causing delays and