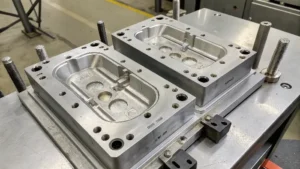

Efficient Mold Flow Analysis for Optimal Injection Molding: How Can It Revolutionize Your Process?

Do you want to prevent costly rework and injection molding production downtime? These issues are typically the result of unexpected problems like warpage or air traps that are devouring your bottom line. Proper mold flow analysis offers a solid solution to forecast and prevent these problems before they occur. Mold