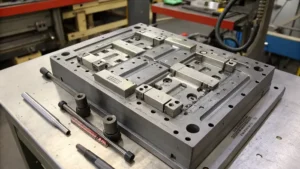

Mold Steel Showdown: P20 vs. H13 vs. S136. How to Choose for Your Mold’s Lifespan and Budget?

Incorrect mold steel selection can ruin a project. It causes premature wear, substandard part quality, and totally blown budgets. Picture your mold breaking in the middle of production, causing huge delays and rework. Getting to know the main differences between P20, H13, and S136 is the beginning of preventing costly