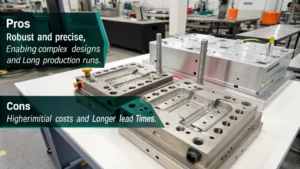

How CKMOLD’s High Pressure Injection Molding Solutions Solved Complex Manufacturing Challenges?

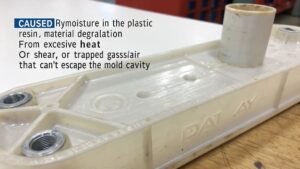

Struggling with tricky plastic parts? Complex designs often lead to frustrating production headaches and delays. It feels like you’re constantly battling defects, doesn’t it? CKMOLD’s approach, particularly with high-pressure injection molding, helps overcome these hurdles. We focus on meticulous design, advanced simulation, and precise process control. This means we can