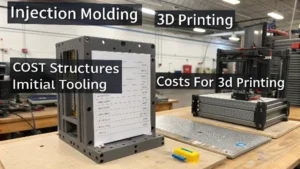

3D Printing vs. Injection Molding in the Automotive Industry: Cost, Quality, and Time Considerations?

When it comes to making car components, deciding between 3D printing and injection moulding may cause a headache. Both are effective, but both carry strengths as well as weaknesses, and opting for the wrong one may result in time being wasted, increased expenses, or a loss of quality. Spur-prototyping and