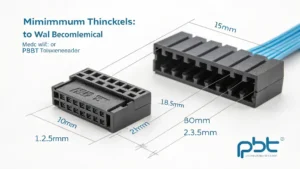

What are the effects of wall thickness on plastic parts, and how can you get it right?

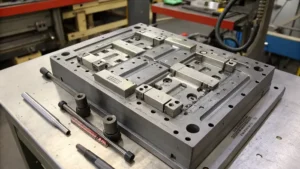

You modeled a flawless looking part in your CAD tool and when you receive the first sets of production the parts returned are deformed, they have unsightly sink marks and other flaws. It is a frustrating procedure that distorts the aspect and merit of the part, creating re-designing of tools