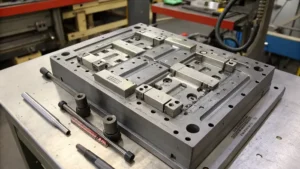

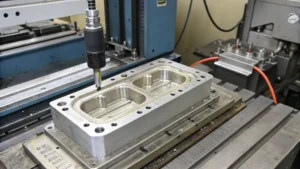

What Are The Basics Of Injection Mold Design? Introduction?

It’s frustrating for a product designer when a great design fails on the production line because of overlooked molding principles. This can lead to budget overruns, missed deadlines, and a flawed final product. Mastering the basics of injection mold design is the essential first step to ensure your vision becomes