What Is the Role of Mold Flow Analysis in Injection Molding?

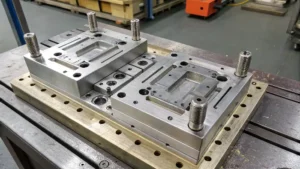

Have you ever invested a lot of time and money in a new mold, only to experience warpage or sink marks on the initial trial run? Such issues lead to costly rework and infuriating delays, sending your whole production schedule into a tailspin. Would it not be wonderful if you