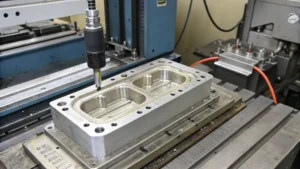

What are the seven basic components of injection molding?

Have you ever created a plastic part that was absolutely perfect on screen, then encountered infinite difficulty during production? A minor mistake in how the part is being molded can result in expensive tooling changes and annoying delays. Learning about the fundamental elements of an injection mold is the first