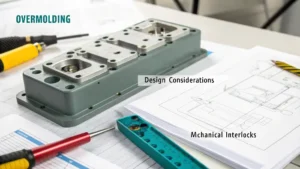

TPU Overmolding Mastery: Techniques, Materials and Process Parameters?

Creating parts with both rigid strength and a soft-touch feel can be a real headache. Separate components mean assembly issues and more chances for things to break. I know this frustration well. Mastering TPU overmolding involves selecting compatible materials, designing molds for strong bonding, and precisely controlling injection parameters like