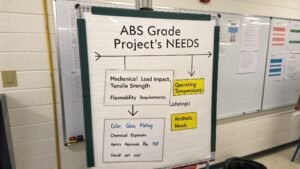

Complete Guide to ABS Grades: How Can You Select the Right Material for Your Injection Molding Project?

Overwhelmed by ABS options? Choosing the wrong grade means project delays and cost overruns. We simplify ABS selection, ensuring your project’s success from the start. Selecting the right ABS grade involves understanding your project’s specific requirements for impact strength, heat resistance, flow characteristics, and any special properties like flame retardancy